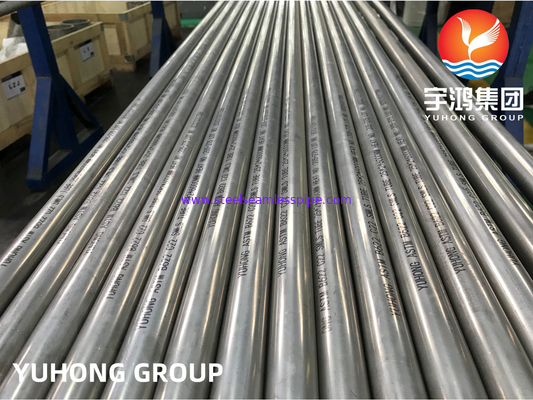

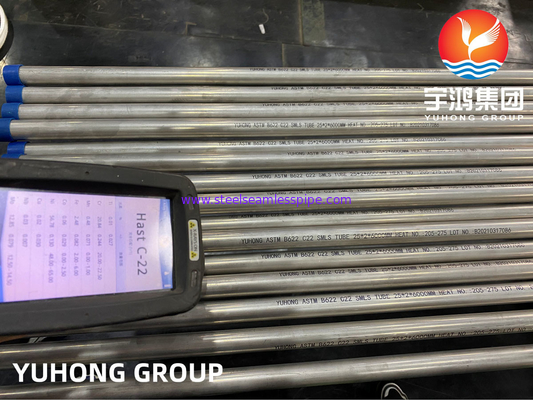

ASTM B622 C22 (UNS NO6022) HASTELLOY STEEL SEAMLESS TUBE ET-ASTM E571 , HT. ET UT-E213

HASTELLOY Alloy C-22 is an alloy composed of nickel, chromium, and molybdenum that offers improved resistance to pitting, crevice corrosion, and stress corrosion cracking. It is highly resistant to the formation of grain boundary precipitates in the heat-affected zone during welding, making it suitable for use in its welded state. C-22 exhibits exceptional resistance to both reducing and oxidizing substances, making it suitable for environments prone to challenging conditions. It has been proven to have excellent weldability and is commonly used as filler wires and electrodes due to its high corrosion resistance. C-22 can be easily shaped through cold-working methods, although it requires more energy compared to austenitic stainless steels due to its stiffness. In a specific example, a 0.28" thick sheet of C-22, heat-treated at 2050°F and rapidly quenched, had an average olsen cup depth of 0.49".

Yuhong Group deal with Nickel base alloy steel pipe , fitting, flange more than 30 years , the detail material grade contain:

Hestalloy:C-276, C-4, C-22, C-2000, X, B-2, B-3, G-30, G-35.

Monel:400,401, 404, R-405, K500.

Inconel:600, 601, 617, 625, 690, 718, 740, X-750.

Incoloy:800, 800H, 800HT, 825, 840, 925, 926

Pure Nickel:Ni-200, Ni-201, Ni-270.

NS Alloy:Ns 1101, NS1102, NS1103,NS3105.

Our products already export more than 55 countries .

Chemistry

Chemical Requirements

|

|

|

Ni

|

Cr

|

Mn

|

C

|

Mo

|

Si

|

Fe

|

|

Max

|

Bal.

|

22.5

|

0.50

|

0.015

|

14.5

|

0.08

|

6.0

|

|

Min

|

|

20.0

|

|

|

12.5

|

|

2.0

|

Tensile Data

Mechanical Property Requirements

|

| |

Ultimate Tensile

|

Yield Strength (0.2% OS)

|

Elong. in 2 in. (50.8mm) or 4D min., %

|

R/A

|

Hardness

|

| Min |

100 KSi |

45 KSi |

45 |

|

|

| Max |

|

|

|

|

|

| Min |

690 MPa |

310 MPa |

|

|

|

| Max |

|

|

|

|

|

Specifications

|

UNS

|

|

Bar

|

ASTM B574

|

|

Wire

|

|

|

Sheet

|

ASTM B575

|

|

Plate

|

ASTM B575

|

|

Fitting

|

ASME SB-366

|

|

Forging

|

ASME SB-564

|

|

Weld Wire

|

AWS A5.14

|

|

Weld Electrode

|

|

HASTELLOY FAMILY OF CORROSION-RESISTANT ALLOYS

| Hastelloy B-3 alloy |

Same excellent resistance to hydrochloric acid and other strongly reducing chemicals as B-2 alloy, but with significantly better thermal stability, fabricability and stress corrosion cracking resistance. |

| Hastelloy HYBRID- BC1 alloy |

A new Ni-Cr-Mo alloy with superior resistance to hydrochloric and sulfuric acids, without the drawbacks of the Ni-Mo and Zr materials. Its resistance to these key chemicals is much greater than that of the popular Ni-Cr-Mo (C-type) alloys, yet it shares with them the outstanding resistance to pitting and crevice attack in chloride salt solutions, and even withstands high levels of oxidizing impurities that the Ni-Mo alloys cannot cope with. |

| Hastelloy C-4 alloy |

High-temperature stability in the 1200-1900°F (650-1040°C) range as evidenced by good ductility and corrosion resistance. Virtually the same corrosion resistance as alloy C-276. |

| Hastelloy C-22 alloy |

Better overall corrosion resistance in oxidizing corrosives than C-4, C-276 and 625 alloys. Outstanding resistance to localized corrosion and excellent resistance to stress corrosion cracking. Best alloy to use as universal weld filler metal to resist corrosion of weldments. |

| Hastelloy C-22HS alloy |

This alloy was designed to exhibit corrosion resistance comparable to other C-type alloys, but which can be heat treated to obtain approximately double the yield strength. |

| Hastelloy C-276 alloy |

Versatile, corrosion resistant alloy. Very good resistance to reducing, and mildly oxidizing corrosives. Excellent stress corrosion cracking resistance with very good resistance to localized attack. |

| Hastelloy C-2000 alloy |

Most versatile, corrosion resistant alloy with excellent resistance to uniform corrosion in oxidizing or reducing environments. Excellent resistance to stress corrosion cracking and superior resistance to localized corrosion as compared to C-276 alloy. |

| Hastelloy G-30 alloy |

Many advantages over other metallic and non-metallic materials in handling phosphoric acid, sulfuric acid, nitric acid, fluoride environments and oxidizing acid mixtures. |

| Hastelloy G-35 alloy |

Excellent resistance to corrosion in highly oxidizing media and acidic chloride environments. |

| Hastelloy N alloy |

Good resistance to aging and embrittlement and good fabricability. It has excellent resistance to hot fluoride salts in the temperature range of 1300°F to 1600°F (705°C-870°C). |

Hastelloy Applications

Hastelloy serves many different applications in these industry categories:

- Chemical Process

- Petrochemical

- Oil & Gas

- Pharmaceutical

- Geothermal

- Sea Water

- Water Desalination

- LNG (Liquefied Natural Gas)

- Biomass

- Mining

- Utilities

- Nuclear Power

- Solar Power

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!