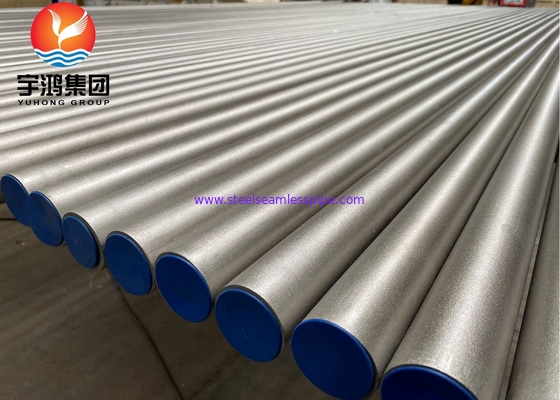

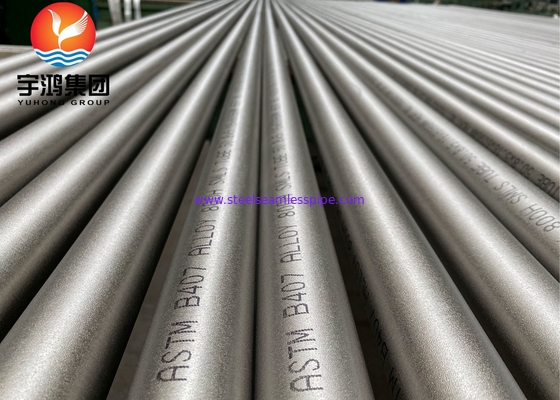

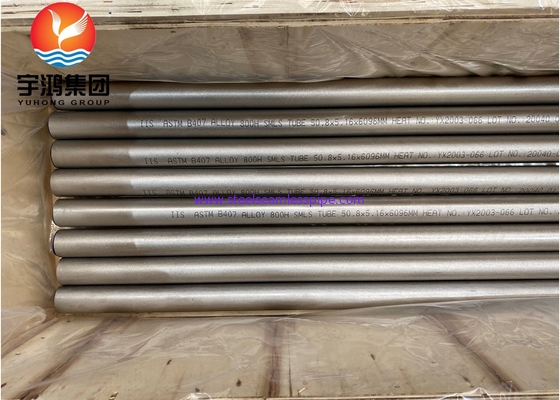

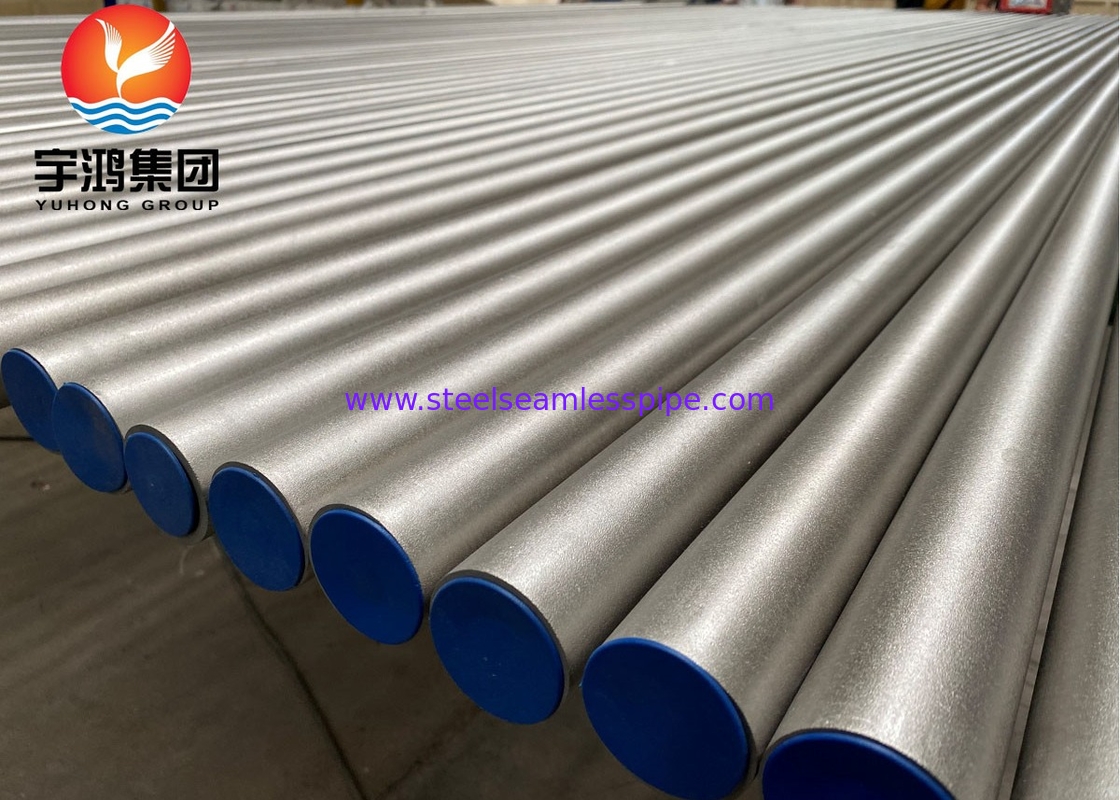

ASME SB407 Incoloy 800H / UNS N08810 Nickel Alloy Steel Seamless Tube

Overview:

Incoloy 800H is a high-performance nickel-chromium-iron alloy known for its excellent resistance to oxidation, carburization, and various corrosive environments. This alloy, often used in the form of seamless tubes, exhibits exceptional mechanical properties at elevated temperatures, making it suitable for industrial applications such as petrochemical processing, power plants, and waste heat recovery systems.

The alloy's composition includes approximately 30% nickel, 20% chromium, and a small amount of titanium, which contributes to its enhanced strength and stability, particularly in high-temperature conditions. Its ability to maintain strength and resist thermal creep makes it ideal for applications where high heat exposure is common.

Incoloy 800H seamless tubes are manufactured through a process that ensures uniform wall thickness and integrity, thus improving their overall durability and reliability. These tubes can withstand pressures and temperatures that would typically degrade other materials, thereby extending service life and reducing maintenance costs.

Moreover, Incoloy 800H is also notable for its ease of fabrication. It can be readily welded and formed into various shapes, making it versatile for different installation requirements. The alloy’s resistance to scaling and oxidation at high temperatures further supports its use in aggressive environments, and it performs well in both oxidizing and reducing conditions.

Specification:

| Specifications |

ASTM B407 & Its equivalent ASME, DIN & EN Standard. |

| Grades |

UNS N08810/Incoloy 800H |

| Type |

U-bend & Straight seamless tube |

| Outside Diameter |

1/4'' to 2'' or custom size |

| Wall Thickness |

BWG25;BWG22;BWG20;BWG18;BWG16;BWG14;BWG12;BWG10 |

| Length |

Upto 6 meters, custom cut lengths |

| Delivery Condition |

Solution Annealed & Pickled |

| Ends |

Plain End, Beveled End |

| Other Testing |

Product Analysis, Eddy Current Test, Hydrostatic Test, Ultrasonic Test, Flattening Test, Hardness Test, Tensile Test etc. |

| Dimension |

All Pipes & Tube Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Packing |

Plywood case/Woven bag in bundle |

Chemical Composition:

| Grade |

Ni |

Cr |

Fe |

Mn |

C |

Cu |

Si |

S |

Al |

Ti |

| UNS N08810 |

30.0-35.0 |

19.0-23.0 |

39.5 min. |

1.5 max |

0.05-0.10 |

0.75 max. |

1.0 max. |

0.015 max |

0.15-0.60 |

0.15-0.60 |

Mechanical Properties:

| Grade |

Tensile Strength

min, ksi (MPa)

|

Yield Strength

min, ksi (MPa)

|

Elongation in 2 in.

or 50mm, min (%)

|

| UNS N08810 |

65(450) |

25(170) |

30 |

Applications:

1. Power Generation: Used in steam boilers and heat exchangers due to its resistance to oxidation and carburization at high temperatures.

2. Chemical Processing: Ideal for harsh environments in chemical plants, especially where acidic conditions are present.

3. Oil and Gas Industry: Employed in downhole tubing and other components that require durability and heat resistance.

4. Nuclear Applications: Used in components that need to withstand high temperatures and corrosive environments.

5. Heat Exchangers: Excellent choice for applications requiring high thermal stability and corrosion resistance.

6. Aerospace and Marine: Suitable for structures where strength and resistance to stress corrosion cracking are critical.

7. Food Processing: Used in equipment that requires high cleanliness standards and resistance to various chemicals.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!