ASME SB163 Inconel 601 Alloy Steel Seamless Tube NDT Available

We are one of the biggest manufactures of stainless steel & duplex steel & alloy steel tubes and pipes in China. With development more than 20 years, we have accumulated a great many clients all around the world and Yuhong products also won the great praise among the customers.

ASME SB163 covers seamless tubes of nickel and nickel alloy for use in condenser and heat-exchanger service. This covers outside diameter and average wall, or outside diameter and minimum wall tube. Tube shall be furnished in the alloys and conditions defined by this specification. The material shall conform to the composition limits of nickel, copper, molybdenum, iron, manganese, carbon, silicon, chromium, aluminium, titanium, phosphorus, cerium, zirconium, yttrium, born, cobalt, columblum, tungsten, and nitrogen specified. Tensile strength, yield strength, elongation, and Rockwell hardness of the material shall conform to the required mechanical properties set by this specification. Test methods such as chemical analysis, tension, rounding procedure, Rockwell hardness, grain size and hardness conversion shall be performed.

Inconel 601 Corrosion resistance: One of the mainly performance of 601 is inexorability in high temperature, even in very inclement conditions. If in the process of heating and cooling cycle, 601 can generate the dense layer of oxide film to get high spalling resistance. 601 have good carbonation resistance. With excellent inoxidability in the high temperature of sulfur atmosphere since it has high chromium and aluminum content.

Inconel 601 Tubes Specification

Pipe Specification : ASTM B163, B516 / ASME SB163, SB516

Size : 1/8″NB TO 30″NB IN

Thickness Range : 0.3mm – 50 mm

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

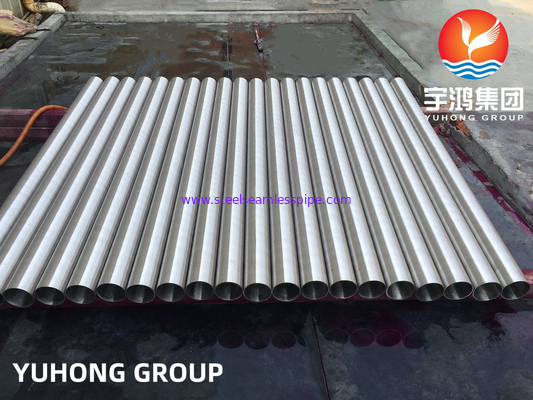

Type : Seamless Tube, Welded Tube, ERW Tube, Fabricated Tube, CDW

Form : Round Tubes, Square Tubes, Rectangular Tube

Length : Single Random, Double Random & Cut Length.

End : Plain End, Beveled End, Threaded

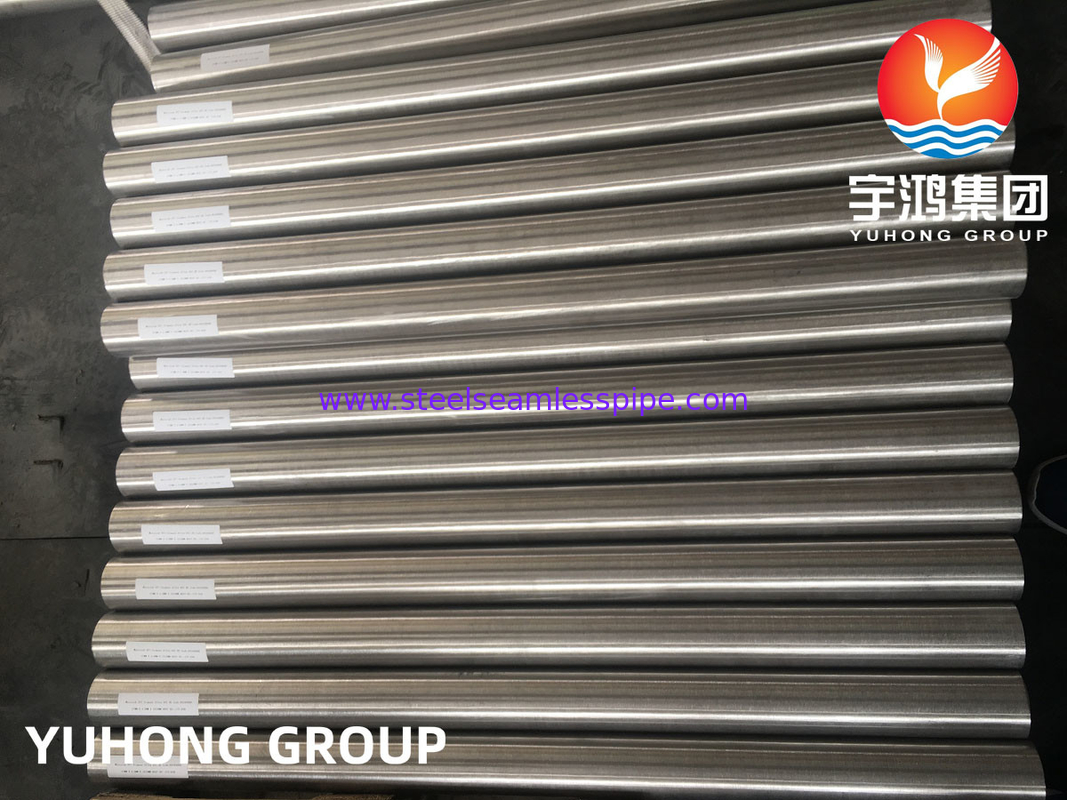

End Protection : Plastic Caps

Outside Finish : 2B, No.1, No.4, No.8 Mirror Finish

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

External Coating : 3LPE / 3LPP/ FBE/ DFBE/ PP

Origin : Indian Origin, European Origin, Japanese Origin.

Testing and Documents : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

Packing : Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

Inconel 601 Nickel Alloy Seamless Tubes Tubing Pipes Characteristic

-

1️⃣ High-Temperature Resistance: One of the primary advantages of Inconel 601 is its exceptional resistance to high temperatures. It can withstand temperatures up to 1200°C (2200°F), making it suitable for applications in extreme heat environments such as furnace components and heat exchangers.

2️⃣ Oxidation and Corrosion Resistance: Inconel 601 exhibits excellent oxidation resistance, even in environments with sulfur compounds and elevated temperatures. Its high chromium content provides protection against corrosive gases, reducing the potential for degradation and extending the service life of the pipes.

3️⃣ Good Mechanical Properties: The combination of nickel, chromium, and iron in Inconel 601 enhances its mechanical properties, providing good tensile strength, yield strength, and toughness. This makes the seamless pipes resistant to deformation and suitable for demanding applications.

4️⃣ Suitability for Various Environments: Inconel 601 seamless pipes offer resistance to a wide range of corrosive environments, including sulfuric acid, hydrochloric acid, nitric acid, and alkaline solutions. This versatility allows them to be used in various industries, such as chemical processing, power generation, and oil and gas.

5️⃣ Excellent Formability: Inconel 601 possesses good formability and weldability, making it easier to fabricate and install. This enables the production of custom-shaped pipes and fittings, ensuring a precise fit for specific applications.

Inconel 601 Nickel Alloy Seamless Tubes Tubing Pipes Chemical Composition

| Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Al |

P |

S |

| ASTM B163 N06601 |

Min. |

58 |

21 |

|

|

|

|

|

1 |

|

|

| ASTM B163 N06601 |

Max. |

63 |

25 |

balance |

0.1 |

1 |

0.5 |

1 |

1.7 |

0.02 |

0.015 |

| Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Cu |

Al |

P |

S |

| ASTM B167 N06601 |

Min. |

58 |

21 |

|

|

|

|

|

1 |

|

|

| ASTM B167 N06601 |

Max. |

63 |

25 |

balance |

0.1 |

1.5 |

0.5 |

1 |

1.7 |

0.02 |

0.015 |

Inconel 601 Nickel Alloy Seamless Tubes Tubing Pipes Mechanical Properties

| Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Inconel 601 |

8.1 g/cm3 |

1411 °C (2571 °F) |

Psi – 80,000 , MPa – 550 |

Psi – 30,000 , MPa – 205 |

30%

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!