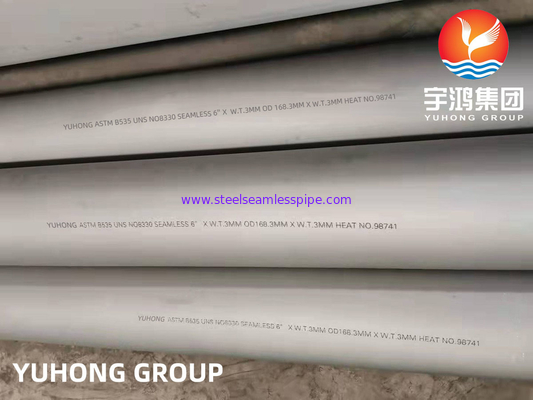

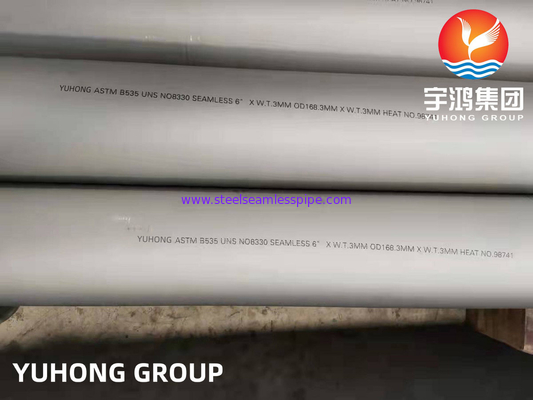

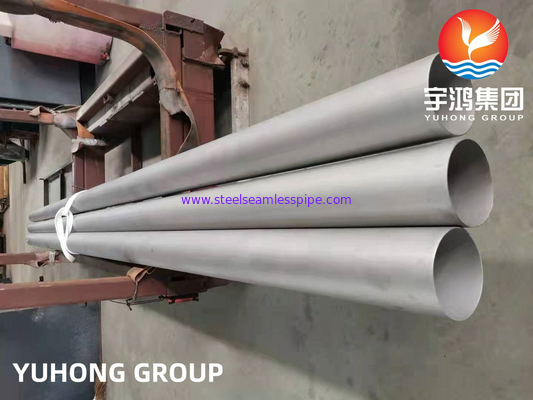

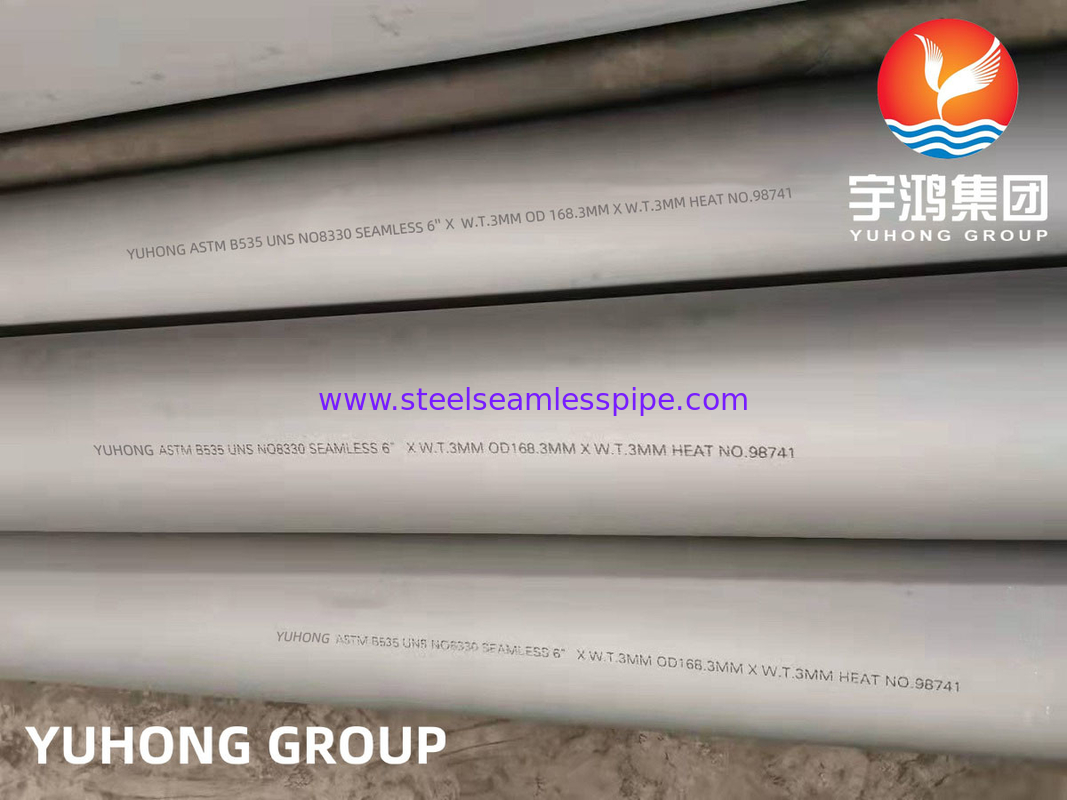

ASTM B535 UNS N08330 Nickel-Iron-Chromium-Silicon Alloy Seamless Tubes

Alloy 330 (UNS N08330) is an austenitic, nickel-chromium-iron-silicon alloy that has outstanding resistance to oxidation and carburization up to 2200°F with high strength. The excellent resistance to oxidation and carburization is provided by the high nickel and chromium content of the alloy, further enhanced by its silicon content. Alloy 330's ultra high nickel content of 34 to 37% also provides high resistance to chloride stress corrosion cracking and embrittlement from the precipitation of sigma phase in most furnace atmospheres. Alloy 330 also has a low coefficient of expansion, excellent ductility, and high strength.

Production Specification

|

ASTM B535

|

Specification for Nickel-Iron-Chromium-Silicon Alloys (UNS N08330 and

N08332) Seamless Pipe and Tube

|

|

ASME SB535

|

|

Material Grade

|

UNS N08330 / UNS N08332

|

|

Size

|

1/2'' - 48''

|

|

Thickness

|

SCH5 - SCHXXS

|

|

End

|

Beveled End, Plain End

|

|

Length

|

As per your requirement.

|

|

Packing

|

Export Standard packing or as per your requirements.

|

ASTM B535 N08330 ASTM B535 Equivalent

| Grade |

Standard |

Area |

Content |

| B535 N08332 |

ASTM B535 |

America |

Nickel-iron-chromium-silicon alloy seamless tube |

| B535 N08330 |

ASTM B535 |

America |

Nickel-iron-chromium-silicon alloy seamless tube |

ASTM B535 N08330 Tube Mechanical Properties

The main mechanical properties are elasticity, plasticity, stiffness, aging sensitivity, strength, hardness, impact toughness, fatigue strength and fracture toughness.

Elasticity: Metal material deforms when it is subjected to external force. When the external force is removed, it can restore its original shape.

Plasticity: The ability of ASTM B535 N08330 ASTM B535 to produce permanent deformation without causing damage under external forces.

Stiffness: The ability of ASTM B535 N08330 ASTM B535 to resist elastic deformation under stress.

Strength: The ability of ASTM B535 N08330 ASTM B535 to resist deformation and fracture under external forces.

Hardness: The ability of ASTM B535 N08330 ASTM B535 to resist the pressure of a harder object into it.

Impact toughness: The ability of ASTM B535 N08330 ASTM B535 to resist fracture under impact loading.

Fatigue strength: The maximum stress that does not cause fracture when ASTM B535 N08330 ASTM B535 is subjected to numerous repeated or alternating loads.

Fracture toughness: a performance index used to reflect ASTM B535 N08330 ASTM B535 is ability to resist crack instability and expansion.

| Tensile Strength – ksi (min.) |

0.2% Offset Yield Strength – ksi (min.) |

Elongation in 2 inches – % (min.) |

Hardness – Rockwell B |

| 70 |

30 |

30 |

90 |

ASTM B535 N08330 Tube Physical Properties

Physical properties of ASTM B535 N08330 ASTM B535 are mainly indicated by modulus of elasticity, thermal conductivity, specific thermal capacity, electrical resistance value, coefficient of thermal expansion, density, poisson's ratio, etc.

Density

(lb. / cu. in.) |

Specific Gravity |

Specific Heat

(Btu/lb Deg F – [32-212 Deg F]) |

Magnetic Permeability |

Modulus of Elasticity Tension |

| 0.289 |

7.99 |

0.11 |

1.02 |

28.5 |

Alloy 330 (UNS N8330) Tube Application

Alloy 330 is extensively used in high temperature environments where resistance to the combined effects of thermal cycling and carburization is necessary. Applications include:

1. Chemical and Petrochemical Processing: cracked ammonia components, petrochemical furnace parts, heat exchangers, flares, etc

2. Thermal Processing: heat-treat furnace containers & compartments, high temperature fans, salt pots, etc

3. Ore Processing: perlite system and equipment

4. Power Generation: boiler fixtures, gas turbine components, etc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!