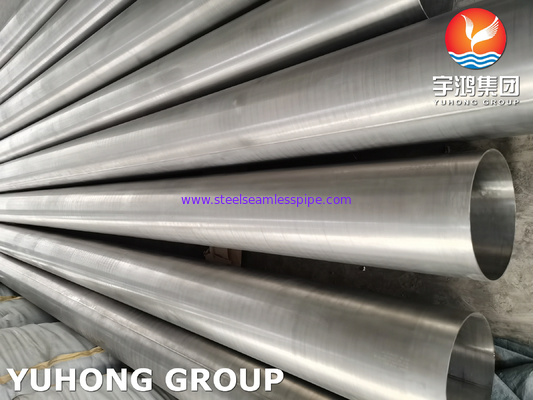

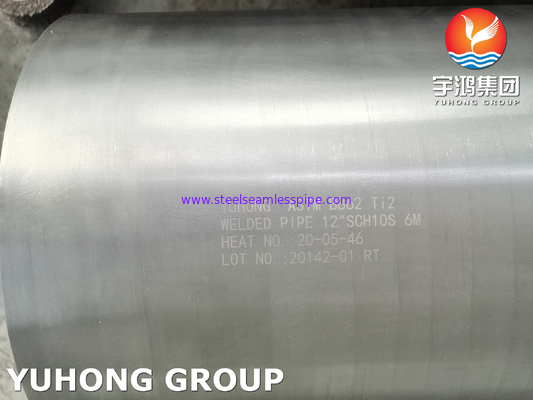

| ASTM B862 Titanium Alloy Pipe Specification |

ASTM B338 / ASTM B861 / ASTM B862 / ASME SB338 / ASME SB861 / ASME SB862 |

| ASTM B862 Titanium Alloy Pipe Grades |

Grade 1 , Grade 2, Grade 3 , Grade 5 , Grade 7, Grade 8, Grade 9, Grade 11, Grade 12, Grade 23, UNS R50250, UNS R50400, UNS R56400, UNS R52400, UNS R56320, UNS R53400, Ti-6Al-4V, C-130AM, C-110M, Ti-4Al-3Mo-1V, Ti-6Al-2Sn-4Zr-2Mo, Ti-8Al-1Mo-1V, Ti-13V-11Cr-3Al, Ti-15V-3Cr-3Sn-3Al |

| ASTM B862 B862 Titanium Alloy Pipe Type |

Hot Rolled / Cold Drawn / Welded / ERW |

| ASTMB862 Titanium Alloy Pipe Outer Diameter Size |

Seamless - 1/4"NB to 12"NB (Nominal Bore Size)

Welded / ERW- 1"NB to 16"NB (Nominal Bore Size) |

| ASTM B862 Titanium Alloy Pipe Wall Thickness |

Schedule 10 to Schedule 160 |

| ASTM B862 Titanium Alloy Pipe Length |

5 to 7 Meters, 09 to 13 Meters, Single Random Length, Double Random Length And Customize Size. |

| ASTM B862 Titanium Alloy Pipe Pipe Ends |

Plain Ends / Beveled Ends |

| ASTM B862 Titanium Alloy Pipe Delivery Conditions |

As Rolled, Cold Drawn, Hot Finish, Stress Relieved, Annealed, Hardened, Tempered |

| ASTM B862 Titanium Alloy Pipe Coating |

Electropolish, Mechanical Polish, Satin Finish, Passivated |

| ASTM B862 Titanium Alloy Pipe Other Testing |

ardness Test, Hydrostatic Test, Eddy Current test, Eddy Current, Tensile Test, Flattening, Flare Test, Annealed, Hydrostatic Test, Tempered, Stress Relieved etc. |

| ASTM B862 Titanium Alloy Pipe Dimension |

All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM And ASME |

| ASTM B862 Titanium Alloy Pipe Value Added Services |

Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| ASTM B862 Titanium Alloy Pipe Packaging |

Loose / Bundle / Wooden Pallet / Wooden Box / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| ASTM B862 Titanium Alloy Pipe Shipment & Transportation |

By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

| ASTM B862 Titanium Alloy Pipe Material Test Certificate |

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!