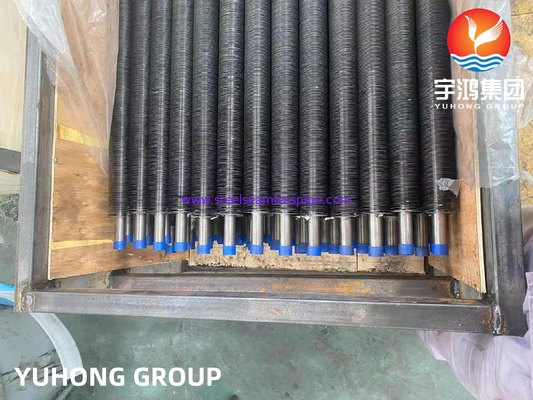

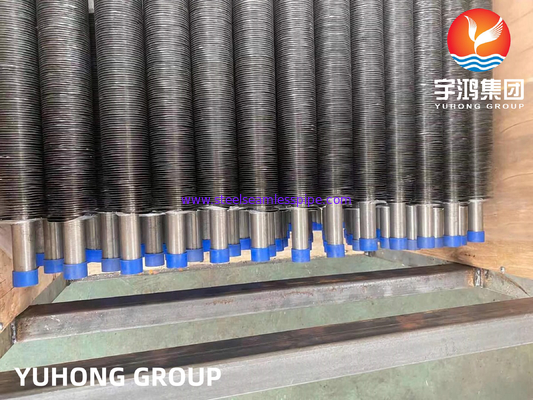

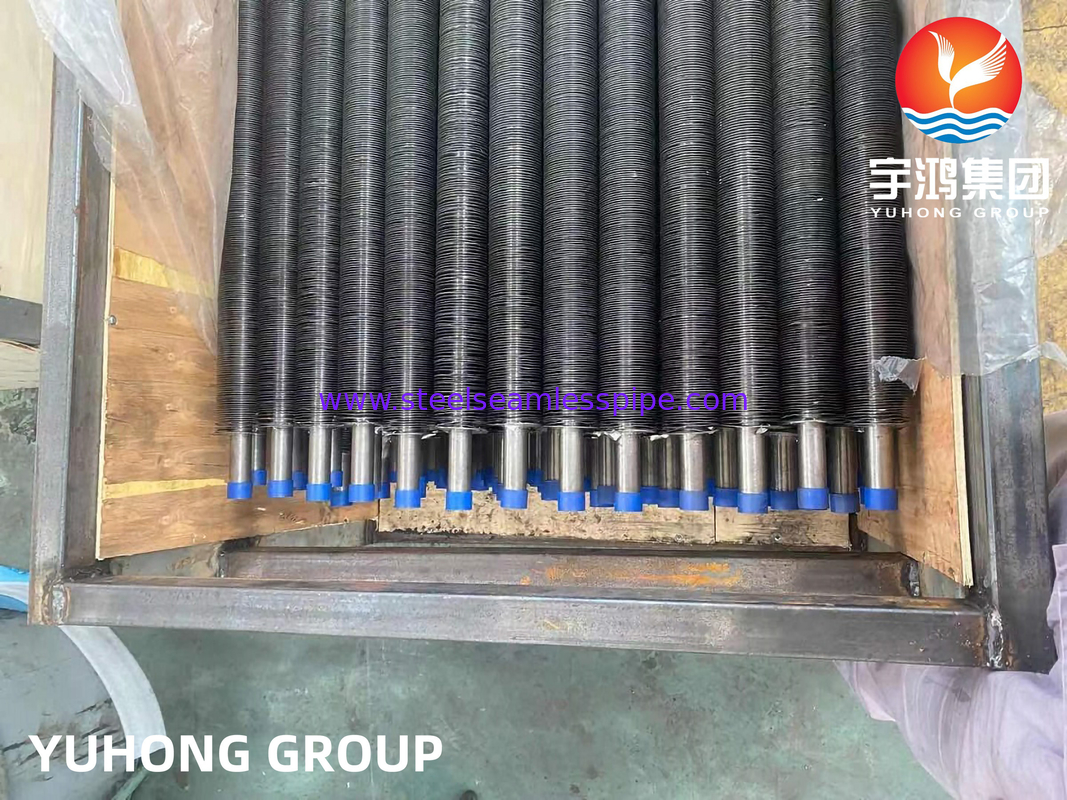

ASME SB163 Monel 400, UNS N04400 Nickel Alloy Tube With Embedded G Type Fin Tube

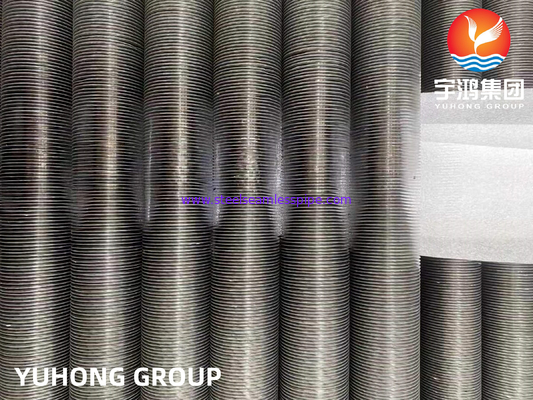

ASME SB163 UNS N04400 Embedded G Type Fin Tube is known for its resistant to seawater and steam at high temperatures. In G-type fin tubes, the fins are prepared by embedding the metal strip into a groove. The latter is formed on a base tube. Placing the fin on it, back-filling is done – resulting in strong attachment of the fins to the base tubes. Hence, the name G-Fin Tubes has come up. The three processes mentioned above are carried out simultaneously. Maximum heat transfer is expected out of the g-fin tubes as the fins are strongly attached to the base tube. The embedded G type fin tubes usually work at high temperature (with around 400 degree Celsius) applications. Made of copper, carbon, or aluminium, these fins have comparatively less resistance towards atmospheric corrosion. On the other hand, mechanical resistance is acceptable. Stainless steel and carbon steel fin materials are also used, but particular processing and tooling of the steel fin strips are necessary. Air coolers, radiators, etc use the g-fin tubes.

G-Type Fin Tube Features:

1. Compact design

2. High-performance

3. Easy installation

4. Less space required

5. Less cabling

6. Optimized surface

7. Finest technology used

8. Average corrosion protection

9. Less energy consumption

10. Increased reliability

11. Low maintenance

12. High mechanical resistance

Technical Details/Base Tube Details:

Tube Diameter : 20 mm OD Min to 219 mm OD Max.

Tube Thickness : Minimum 2 mm up to 16mm

Tube Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, CK 20 material and some other material.

For a rapid quotation, plz send with following requirement:

Number of pieces

base tube: Diameter, thickness, length and material specification.

Fins: material specification, type (solid or serrated), height, thickness, spacing, finned length and unfinned sections. Weld prep details if required.

Delivery period required.

Chemical Composition:

| Grade |

C |

Mn |

Si |

S |

Cu |

Fe |

Ni |

| Monel 400 |

0.30 max |

2.00 max |

0.50 max |

0.24max |

28.0-34.0 |

2.50 max |

63.00 min |

Mechanical Properties:

| Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Monel 400 |

8.8 g/cm3 |

1350 °C (2460 °F) |

Psi – 80,000 , MPa – 550 |

Psi – 35,000 , MPa – 240 |

40 % |

Physical Properties:

| Properties |

Metric |

Imperial |

| Density |

8.8 gm/cm3 |

0.318 lb/in3 |

Industries where G-Type Fin Tubes are used:

1. Rubber plants

2. Power plants

3. Petroleum industries

4. Chemical industries

Other Applications:

1. Marine engineering.

2. Chemical and hydrocarbon processing equipment.

3. Gasoline and freshwater tanks.

4. Crude petroleum stills.

5. De-aerating heaters.

6. Boiler feed water heaters and other heat exchangers.

7. Valves, pumps, shafts, fittings, and fasteners.

8. Industrial heat exchangers.

9. Chlorinated solvents.

10. Crude oil distillation towers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!