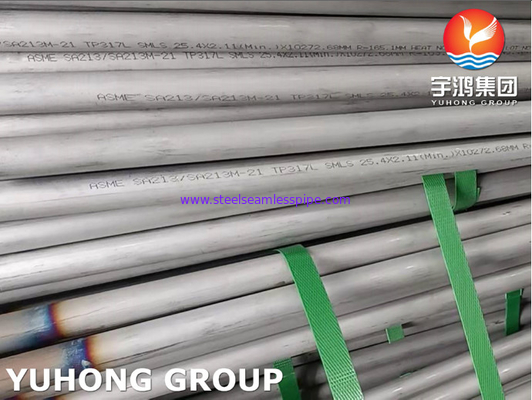

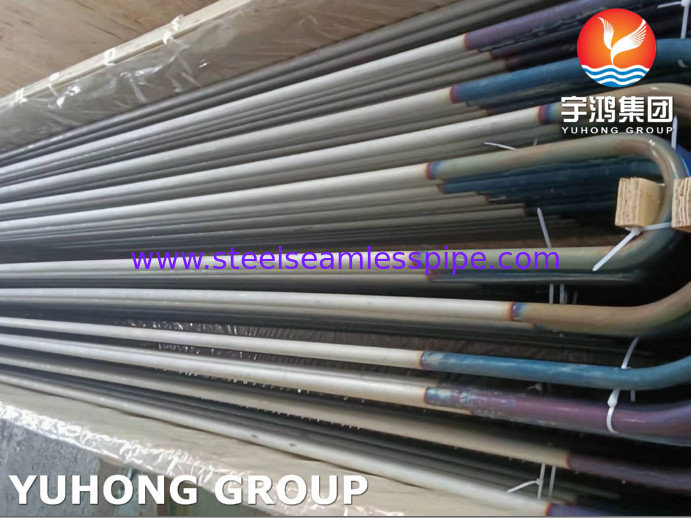

Stainless Steel U Tube ASTM A213 TP317L SMLS For Heat Exchanger

Yuhong Group has been operating stainless steel/duplex/nickel seamless steel pipes for more than 32 years, with annual sales of more than 80,000 tons of stainless steel/duplex/nickel seamless steel pipes.

Our customers have covered more than 65 countries around the world. Our stainless steel seamless pipes are widely used in petrochemical, chemical, mining, energy, food mills, paper mills, gas and fluid industries, etc.

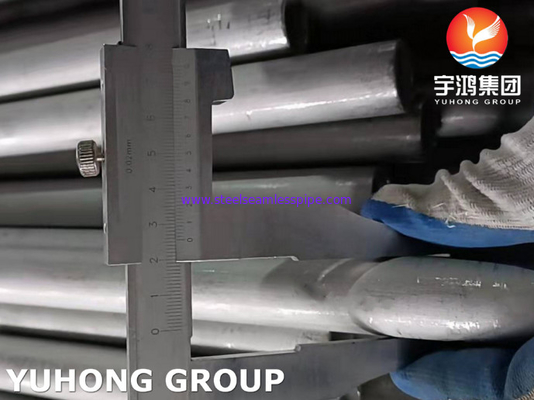

Tubing Size: 1/8″NB to 30″NB IN

Specialty: Large Diameter Sizes

Tubing schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Tube Type: Seamless / ERW / Welded / Fabricated / LSAW Tube

Form: round, square, rectangular, hydraulic, etc.

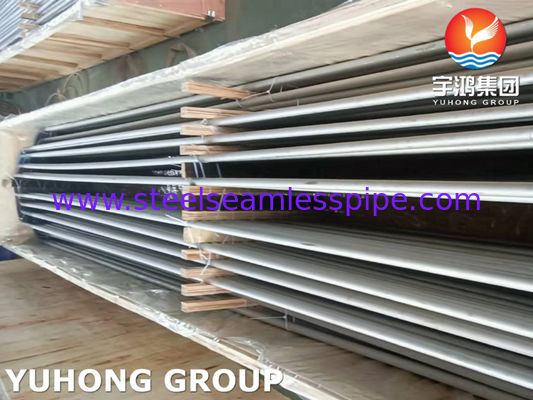

Lengths: single random, double random and cut length.

Tubing end: flat end, beveled end,

Stainless steel is often referred to as corrosion resistant steel - it does not stain, corrode or rust as easily as regular carbon steel. However, it would be misleading to say that it is corrosion resistant. It differs significantly from standard carbon steel due to its chromium content, which limits surface corrosion, which can rust when exposed to air and any moisture in the atmosphere. Stainless steel is often a popular solution due to its antioxidant properties.

Stainless Steel Seamless (SMLS) pipe is formed by drawing a solid billet over a perforated rod to form a hollow shell. Since the manufacturing process does not include any welding, seamless pipes are considered stronger and more reliable. Historically, seamless pipe has been considered to withstand pressure better than other types and is generally more readily available than welded pipe.

317L stainless steel is a low carbon version of 317 stainless steel. It has the same high strength and corrosion resistance as 317 steel, but produces stronger welds due to its low carbon content.

Alloy 317L (UNS S31703) is a molybdenum-containing austenitic stainless steel with significantly improved chemical resistance compared to conventional chromium-nickel austenitic stainless steels such as alloy 304. Additionally, Alloy 317L has higher creep, stress-fracture and tensile strength at elevated temperatures than conventional stainless steels. It is a low carbon or "L" grade that provides resistance to sensitization during welding and other thermal processes.

317L is a molybdenum-containing, low carbon content "L" grade austenitic stainless steel that offers increased corrosion resistance compared to 304L and 316L stainless steels. Low carbon provides sensitization resistance during welding and other thermal processing.

317L is non-magnetic in the annealed condition, but may become slightly magnetic by welding.

317L has excellent corrosion resistance in a variety of chemicals, especially in acidic chloride environments such as those encountered in pulp and paper mills. The increased chromium, nickel and molybdenum content increases resistance to chloride pitting and general corrosion compared to 316L stainless steel. The resistance increases with the molybdenum alloy content. The 317L can tolerate sulfuric acid concentrations up to 5% at temperatures up to 120°F (49°C). This alloy has excellent resistance to highly concentrated solutions at temperatures below 100°F (38°C). However, service testing is recommended to take into account the effects of specific operating conditions that may affect corrosion behavior. 317L is more resistant to corrosion than traditional alloy 316 at the condensation point during the condensation of sulfur-containing gases. Acid concentration has a significant effect on corrosion rates in such environments and testing should be carefully determined based on service.

Chemical Composition of 317L

| Element |

Content (%) |

| Iron, Fe |

Balance |

| Chromium, Cr |

18-20 |

| Nickel, Ni |

11-15 |

| Molybdenum, Mo |

3-4 |

| Manganese, Mn |

2 |

| Silicon, Si |

1 |

| Phosphorous, P |

0.045 |

| Carbon, C |

0.03 |

| Sulfur, S |

0.03 |

| Properties |

Metric |

Imperial |

| Tensile strength |

595 MPa |

86300 psi |

| Yield strength |

260 MPa |

37700 psi |

| Modulus of elasticity |

200 GPa |

29000 ksi |

| Poisson’s ratio |

0.27-0.30 |

0.27-0.30 |

| Elongation at break (in 50 mm) |

55% |

55% |

| Hardness, Rockwell B |

85 |

85

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!