| Shapes |

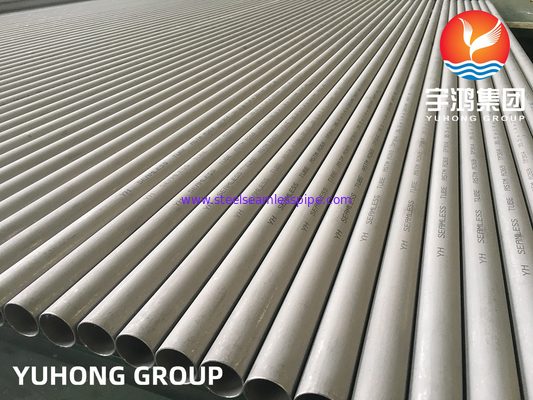

Round, Rectangular, Square, Hydraulic, Straight, "U" Shape, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type |

Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100% X Ray Welded |

| Delivery Condition |

Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Surface Finish |

BA, 2B, No.4, No.1, No.3, No.8, 8K, HL, 2D, 1D, Mirror Polished, 180G, 320G, 400G Satin/ Hairline, 400G, 500G, 600G or 800G Mirror finish Tubing or Custom Finish as per customer's specification |

| Thickness Range |

SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS, SCH XS |

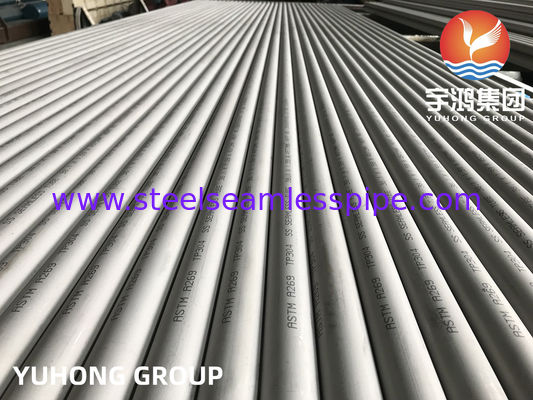

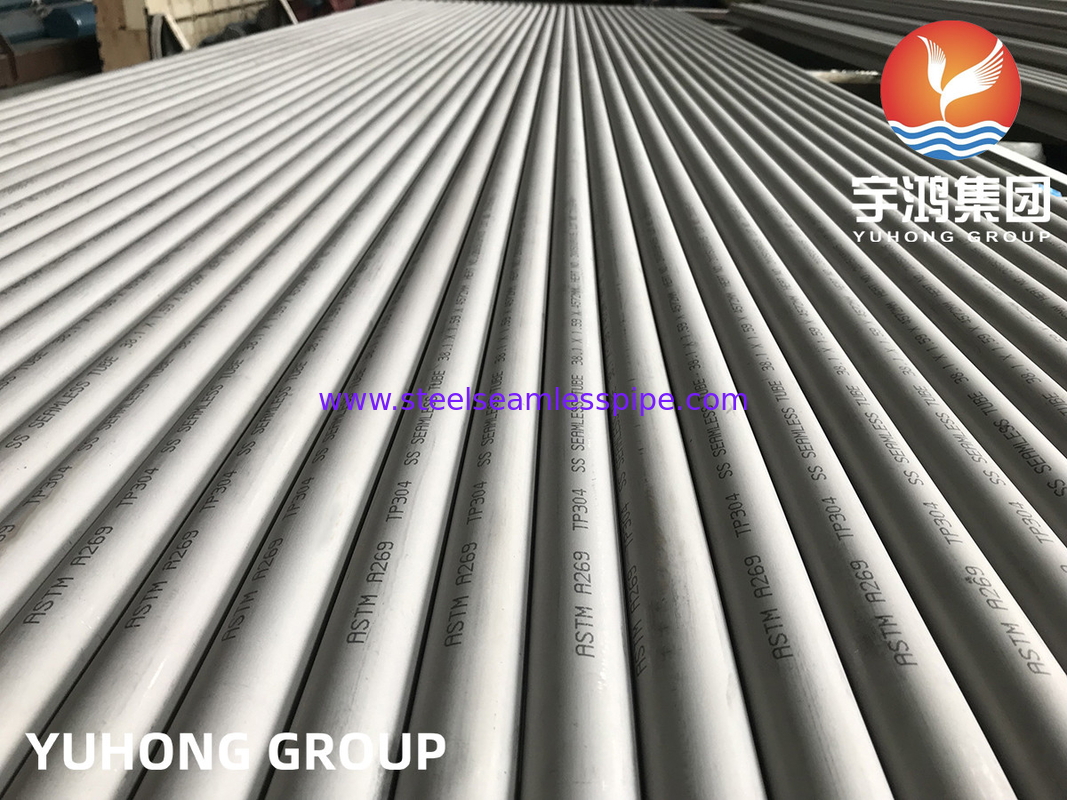

| Standard |

SUS, JIS, AISI, ASTM, GB, DIN, EN |

| Relevant Standard |

ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A554, ASTM A249, ASTM A269, ASTM A270, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 |

| Value Added Services |

- Cutting

- Beveling

- Threading

- Polishing (Electro & Commercial)

- Draw & Expansion as per required Size & Length

- Destructive and Non Destructive

- Ultrasonic Testing

- Annealed & Pickled Bending

|

| Swg & Bwg |

10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| END |

Plain End, Beveled End, Treaded |

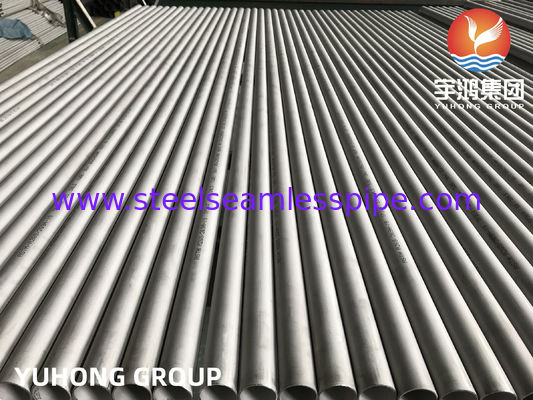

| Processing Service |

Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Technique |

Cold drawn, Cold rolled, Hot rolled, Extrusion Tube |

| Test Certificate |

- DFARS compliant

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- 100% Radiography Test Report

- Raw Materials Certificate

- Third Party Inspection Report

- Fumigation Certificates

- Heat Treatment Charts

- HS Code Commercial Invoice

- Form A for Generalized System of Preferences (GSP)

- Manufacturer Test Certificate

- Moisture testing

- Surface roughness measurement

- Laboratory Test Certificate from Govt. Approved Lab

|

| Packing |

Ends Capped, Sleeved, Wooden Boxed |

| |

|

| Uses & Application |

- Common industrial services (Petroleum, chemical, paper, fertilizer, fabric, aviation and nuclear)

- Fluid, gas and oil industry

- Heat transmission and pressure service

- Construction and ornamental

- Boilers and Heat exchangers

- Decoration purpose, boiler, auto parts, medical device, food industry, building materials)

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!