ASTM A213 / ASME SA213 TP304/TP316L/TP321 / TP321H /TP347H 3/4" , Stainless Steel U Bend Tube For Heating Application, 100% ET & HT

SA213 TP304 is a range of minimum wall thickness pipe series. We supply the SA 213 TP 304 Pipes in different types, shapes and sizes. The SA 213 Tp 304 Material consists of 18% chromium and carbon, manganese, phosphorus, sulfur, silicon and nickel in the composition. There is also the molybdenum, nitrogen, niobium and titanium addition in trace quantities. The SA 213 Tp 304 Density is lower than the ordinary 304 material. It is 7.8 grams per cubic centimeter. We offer ASTM A213 TP 304 for high temperature services. Our 304 Stainless Steel Tube components are of less absolute roughness which means they could be used in high precision equipment and applications.

YUHONG GROUP deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy , Monel, Inconel, Incoloy ) seamless and welded pipe and tube already more than 25 years, every year sell more than 80000 tons of steel pipe and tube. Our client already cover more than 45 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Korea, Singapore, Austrial, Poland, France , ....And our group branch company and factory have been already approved by :ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

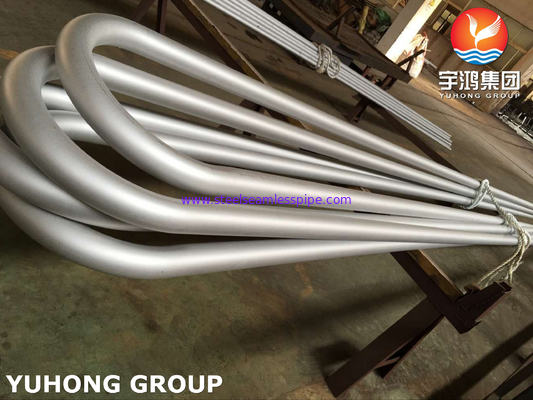

U-Bend Tube are widely used in Heat Exchanger Systems. Heat-Exchanger Equipment on the basis of

Seamless Stainless U-Tubes and Welded Stainless U bend Tube is essential in strategically important and

critical felds---Nuclear And Petrochemical Machine Building.

The U-Bend Tube Comply With The Following Standards:

1. ASTM A688/ASME SA688

2. ASTM A803/ASME SA803

3. ASTM A556/ASME SA556

Steel Grade:

| Ferrite |

Austenite |

Duplex |

Super Duplex |

Ni-Alloys |

Titanium |

|

TP410

TP405

S44400

S44660

TP430

|

TP304/304L

TP316/316L

TP316Ti

TP317/317L

TP321

TP347

|

S31803

S32205

S32304

|

S32750

S32760

|

N06600

N08020

N00880

N08825

N08904

|

Gr.2 |

Tube Of Other Alloys And Steel Grades Can Be Produced Upon Agreement.

Technical Requirements:

Straight Tubes Standard Specification For Bending:

ASME SA 213; ASME SB 163; ASME A789, ASME SA268, ASME SA269, etc.

Marking: Before Bending By Marking Machine All Over The Tube Length (Bent Section After Heat

Treatment Without Marking)

Note: Marking is also possible After Bending On The Straight Parts Of U-Bending Tube.

U-Bend Tubes:

- TEMA RCB 2.31 Standard Of The Tubular Exchanger Manufacturers Association (9th Edition).

- ASTM A688/ASME SA688 Standard Specification For Welded Tubes Of Austenitic Corrosion Resistant

Steel Grade Designed For Feed Water Boilers.

- ASTM B163/ASME SA163 Standard Techinical Requirements For Tubes Of Nickel And Nickel Alloy For

Condensers And Heat Exchangers.

Customer Specifications.

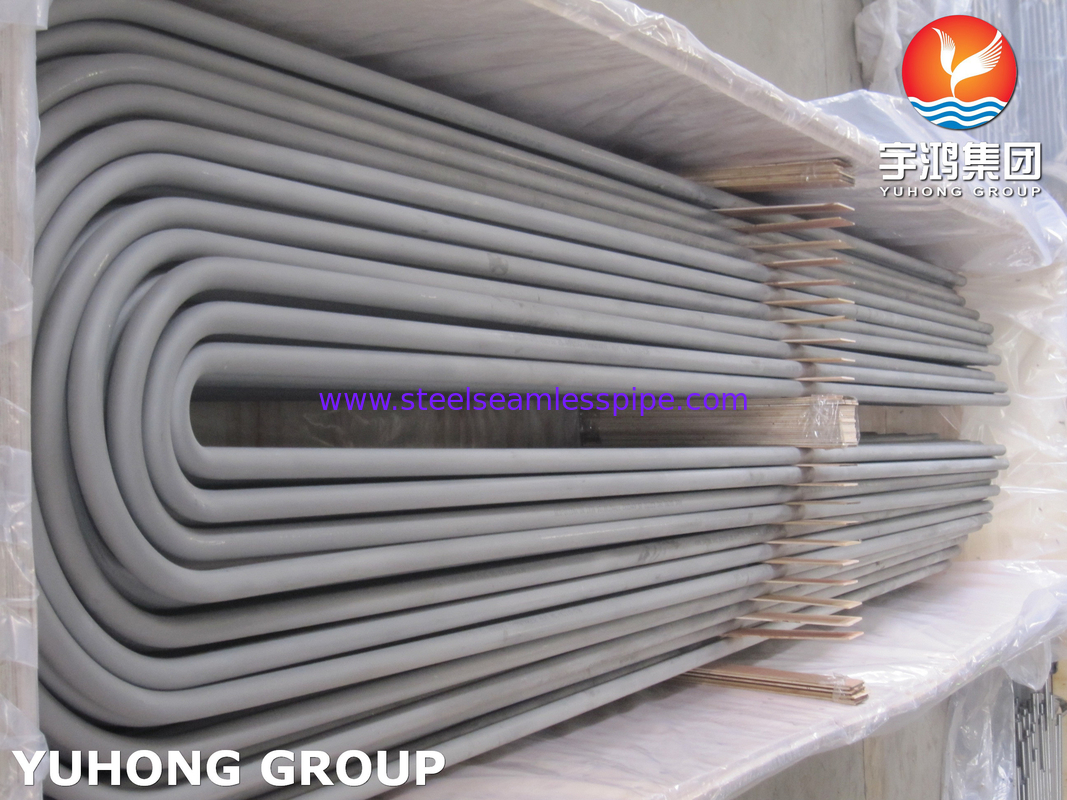

Bending Radius: From 1.5*OD(Outside Diameter) To 1500mm

When Ordering Tubes With Radius less or equal to 1.5*OD, It Is Necessary To Agree Precision Of Geometrics.

Straight Tubes Maximum Length:(Before Bending): 35000 mm.

Leg Length: Min 1 Meter, Max. 16500 mm (For Max R=1500mm)

Note: Other Size Are Available Upon Agreement.

Heat Treatment: Stress Relieved After U-Bending (Bending Area Plus 300MM For Each Leg).

Hydrostatic Test After U Bending: Maximum Test Pressure 600 Bar, Soaking 10 Sec. With

Dematerialized Water. Compressed Air Cleaning After Hydro-Test.

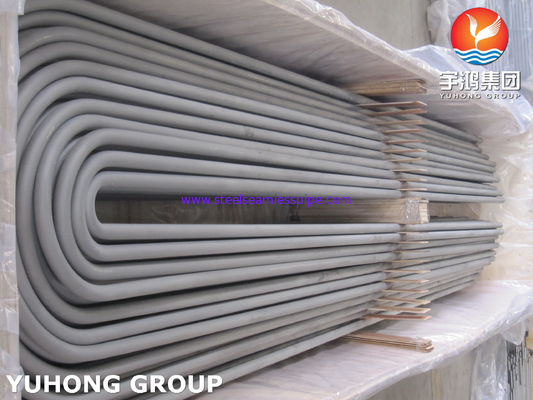

Packaging: In Strong Transport-Worthy Pre-fumigated wooden boxes of corresponding dimensions for

each tube Length, Radius, Diameter, According To PO requirements as well as wrapped In polyethylene

films With soft plastic caps on both end of Tube.

Some of the quality tests carried out by us includes:

| Corrosion Test |

Conducted only when specially requested by the client |

| Chemical Analysis |

Test done as per required quality standards |

| Destructive / Mechanical Testing |

Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests |

Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing |

Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing |

100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test |

To check any evidence of air leakage |

| Visual Inspection |

After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

- Eddy Current Testing

- O.P Testing

- Radiography Testing

|

- Corrosion Testing

- Micro Testing

- Macro Testing

|

- IGC Testing

- Ultrasonic testing

- Liquid Penetrate testing

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!