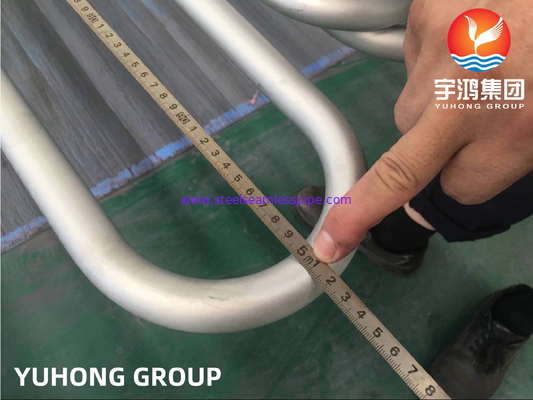

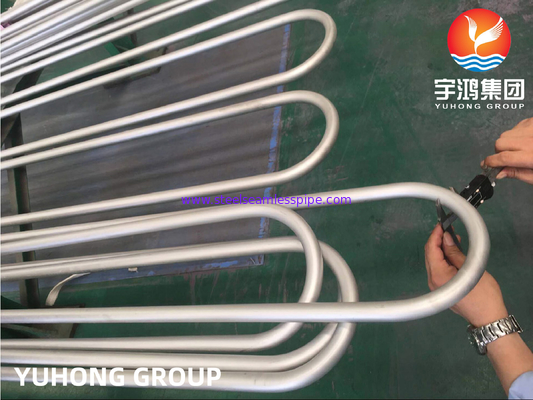

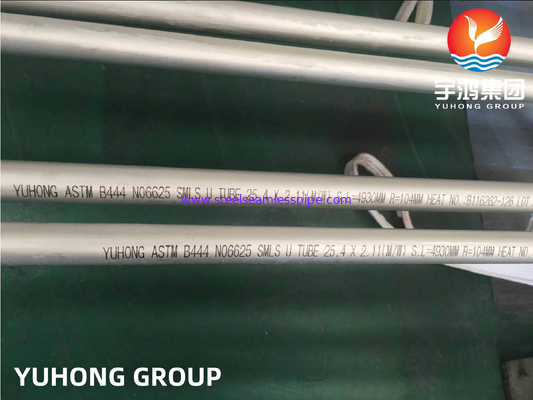

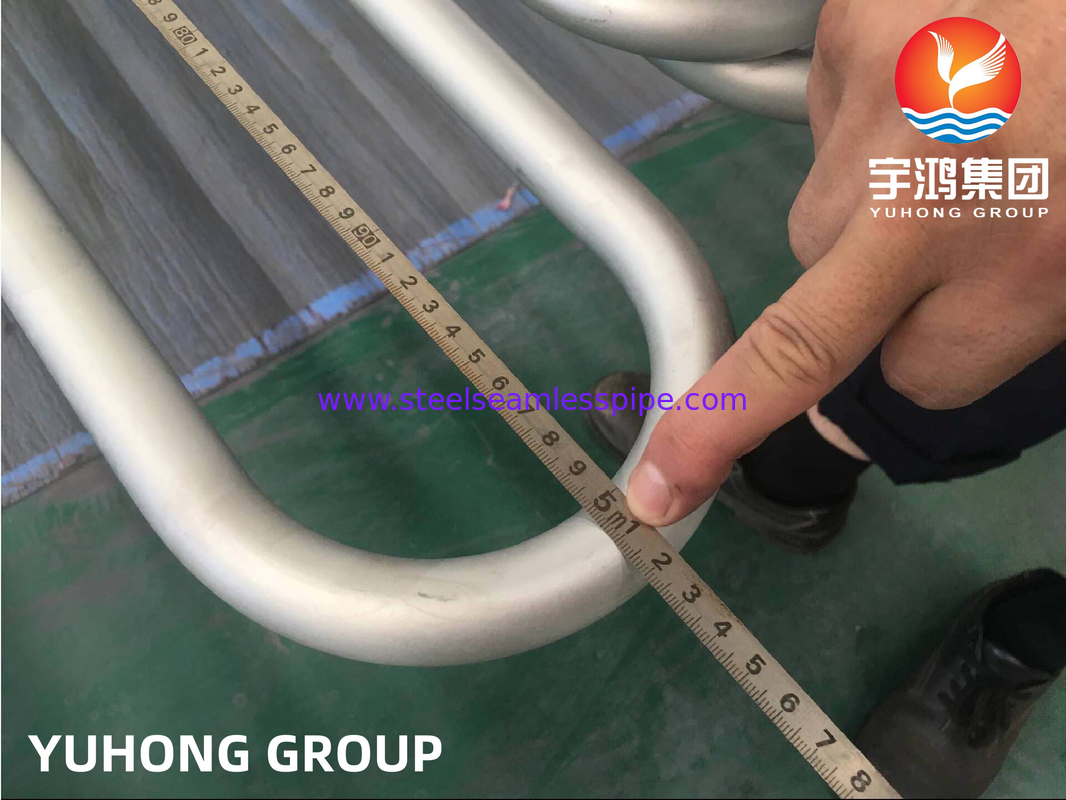

Corrosion Resistance ASTM B444 N06625 Inconel Seamless U Bend Tube

ASTM B444 covers nickel-chromium�molybdenum-columbium alloys (UNS N06625 and UNS N06852) and nickel-chromium-molybdenum-silicon alloy (UNS N06219) in the form of cold-worked seamless pipe and tube.

What is Inconel 625?

Inconel 625 is a corrosion and oxidation resistant nickel alloy used for its high strength and excellent resistance to aqueous corrosion. Its excellent strength and toughness are due to the addition of niobium, which, together with molybdenum, hardens the matrix of the alloy.

Alloy 625 has excellent fatigue strength and resistance to stress corrosion cracking from chloride ions. This alloy resists a wide range of severely corrosive environments and is particularly resistant to pitting and crevice corrosion.

Corrosion Resistance of Inconel

Inconel 625 has corrosion resistance to many environments. In mild environments such as atmosphere, fresh water and sea water, neutral salts and alkaline media there is almost no attack. In more aggressive media nickel and chromium resist oxidising attack, while nickel and molybdenum resist reducing environments.

Molybdenum provides exceptional resistance to pitting and crevice corrosion, and niobium stabilises against sensitisation and intergranular corrosion. The nickel content makes Inconel 625 essentially free from chloride ion stress corrosion cracking. Inconel 625 also has excellent corrosion fatigue properties.

UNS N06625 products are furnished in two grades of different heat-treated conditions:

1.1.1.1 Grade 1 (annealed)—Material is normally employed in service temperatures up to 1100°F (593°C).

1.1.1.2 Grade 2 (solution annealed)—Material is normally employed in service temperatures above 1100°F (593°C) when resistance to creep and rupture is required.

Chemical Composition of N06625:

| (Ni) Nickel |

58.0 min |

| (Cr) Chromium |

20.0 to 23.0 |

| (Fe) Iron |

5.0 max |

| (Mo) Molybdenum |

8.0 to 10.0 |

| (Nb+Ta) Niobium+Tantalum |

3.15 to 4.15 |

| (Co) Cobalt* |

1.0 max |

| (Mn) Manganese |

0.50 max |

| (Si) Silicon |

0.50 max |

| (C) Carbon |

0.40 max |

| (Ti) Titanium |

0.40 max |

| (Al) Aluminum |

0.10 max |

| (P) Phosphorus |

0.015 max |

| (S) Sulfur |

0.015 max |

N06625 Material Equivalent

| Grade |

UNS No |

Old British |

Euronorm |

GOST |

Japanese JIS |

| BS |

En |

No |

AFNOR |

| Alloy 625 |

N06625 |

NA 21 |

NiCr22Mo9Nb |

2.4856 |

NC22DNB4M |

ХН75МБТЮ |

NCF 625 |

Inconel 625 Mechanical and Physical Properties:

| PROPERTY |

21°C |

204 °C |

316 °C |

427 °C |

538 °C |

649 °C |

760 °C |

871 °C |

| Ultimate Tensile Strength /Mpa |

992.9 |

923.9 |

910.1 |

910.1 |

896.3 |

820.5 |

537.8 |

275.8 |

| 0.2% Yield Strength /MPa |

579.2 |

455.1 |

434.4 |

420.6 |

420.6 |

413.7 |

406.8 |

268.9 |

| Elongation % |

44 |

45 |

42.5 |

45 |

48 |

34 |

59 |

117 |

| Coefficient of Thermal Expansion µm/m⁰C |

- |

13.1 |

13.3 |

13.7 |

14 |

14.8 |

15.3 |

15.8 |

| Thermal Conductivity /kcal/(hr.m.°C) |

8.5 |

10.7 |

12.2 |

13.5 |

15 |

16.4 |

17.9 |

19.6 |

| Modulus of Elasticity/ MPa |

2.07 |

1.93 |

1.93 |

1.86 |

1.79 |

1.65 |

1.59 |

- |

Applications:

-Heat shields

-Tubing

-Combustion and chimney liners

-Distillation columns

-Bubble caps

-Reaction vessels

-Heat exchangers

-Furnace hardware

-Gas turbine engine duct work

-Equipment used to produce acid

-Sour gas production tubes

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!