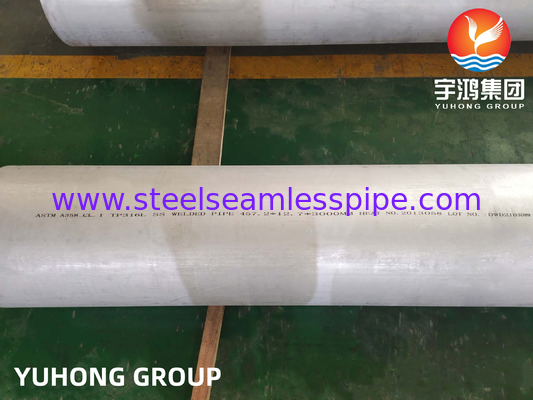

ASTM A358 CLASS 1 TP316L Stainless Steel Welded Pipes for Refineries

YUHONG GROUP with stainless steel seamless pipe and tube already more than 33 years, every year sell more than 12000 tons of stainless steel seamless pipe and tube. Our client already cover more than 65 countries.

Overview

Composition: TP316L contains a lower carbon content compared to TP316, which enhances its resistance to sensitization - a process that can lead to corrosion in certain environments. The composition typically includes elements such as chromium, nickel, molybdenum, and sometimes small quantities of elements like titanium and manganese.

Corrosion Resistance: Like other austenitic stainless steels, TP316L demonstrates excellent corrosion resistance in various environments, including corrosive acids, chloride-containing solutions (such as seawater), and high-temperature applications. Its low carbon content aids in preventing carbide precipitation in the heat-affected zones during welding, thereby reducing the susceptibility to intergranular corrosion.

Applications: TP316L stainless steel pipes are commonly used in industries where corrosion resistance, strength, and high-temperature performance are critical. These applications can include chemical and petrochemical processing, pharmaceuticals, food processing, marine environments, heat exchangers, and various high-temperature services.

Manufacturing Standards: TP316L stainless steel pipes are produced according to ASTM standards, ensuring consistency in mechanical properties, dimensions, and quality.

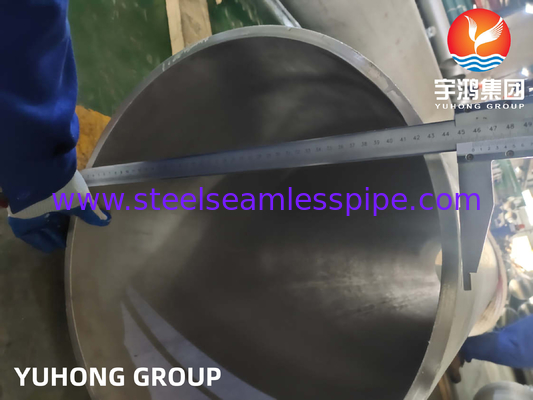

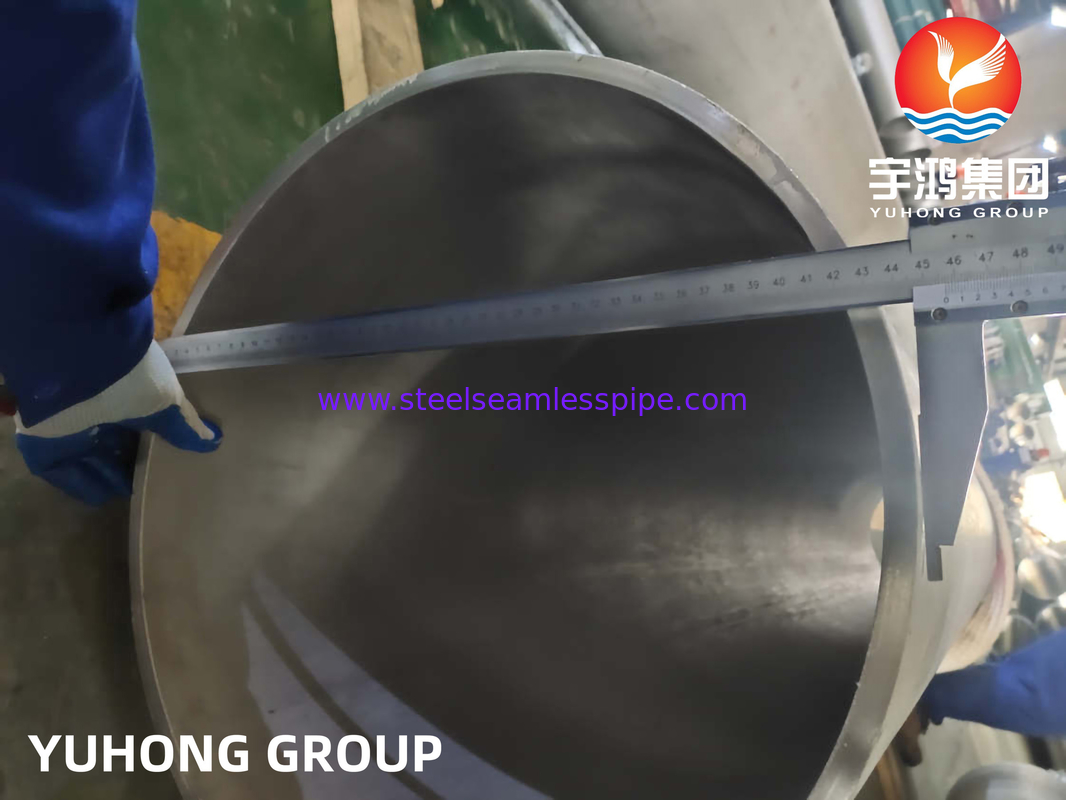

Types and Sizes: TP316L pipes come in various forms such as seamless, welded, and heavily cold worked pipes. They are available in a range of sizes and dimensions to suit different applications.

Welding and Fabrication: TP316L is easily welded using standard welding techniques. Post-weld annealing may be necessary to restore corrosion resistance and eliminate sensitization in the heat-affected zone.

High Temperature Performance: TP316L exhibits good strength and creep resistance at elevated temperatures, making it suitable for applications involving high heat.

Cost and Availability: TP316L stainless steel pipes are readily available in the market, but their cost can vary based on factors such as size, type, quantity, and current market conditions.

When selecting TP316L stainless steel pipes for a specific application, considerations should include the intended environment, pressure, temperature, and required mechanical properties to ensure optimal performance and longevity.

What is TP316L Stainless Steel Pipes

Stainless Steel 316L tubing is made from austenitic stainless steel with chromium, nickel, and molybdenum in its composition, with a carbon content below the 316 grade. The low carbon content of this tubing makes it easier to use in welding applications.

316L stainless steel tubing is suitable for use in aqueous environments where chloride ions are highly corrosive. Because of the molybdenum content of the material, it has a lower corrosion rate in chloride-rich environments. Steel pipe is classified as welded, seamless and fabricated.

EQUIVALENT GRADES FOR STAINLESS STEEL TP316 / 316L CLASS 1 EFW PIPES

|

STANDARD

|

WERKSTOFF NR.

|

UNS

|

JIS

|

BS

|

GOST

|

AFNOR

|

EN

|

|

SS 316

|

1.4401 / 1.4436

|

S31600

|

SUS 316

|

316S31 / 316S33

|

-

|

Z7CND17-11-02

|

X5CrNiMo17-12-2 / X3CrNiMo17-13-3

|

|

SS 316L

|

1.4404 / 1.4435

|

S31603

|

SUS 316L

|

316S11 / 316S13

|

03Ch17N14M3 / 03Ch17N14M2

|

Z3CND17-11-02 / Z3CND18-14-03

|

X2CrNiMo17-12-2 / X2CrNiMo18-14-3

|

STAINLESS STEEL 316, 316L CLASS 1 EFW PIPES CHEMICAL COMPOSITION

|

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

|

SS 316

|

0.08 max

|

2.0 max

|

1.0 max

|

0.045 max

|

0.030 max

|

16.00 - 18.00

|

2.00 - 3.00

|

11.00 - 14.00

|

67.845 min

|

|

SS 316L

|

0.035 max

|

2.0 max

|

1.0 max

|

0.045 max

|

0.030 max

|

16.00 - 18.00

|

2.00 - 3.00

|

10.00 - 14.00

|

68.89 min

|

MECHANICAL PROPERTIES OF STAINLESS STEEL TP316 / 316L CLASS 1 EFW PIPES

|

Density

|

Melting Point

|

Tensile Strength

|

Yield Strength (0.2%Offset)

|

Elongation

|

|

8.0 g/cm3

|

1400 °C (2550 °F)

|

Psi – 75000 , MPa – 515

|

Psi – 30000 , MPa – 205

|

35 %

|

APPLICATION

RefineriesRefineries

- Refineries

- Petrochemicals Industry

- Oil&Gas Industry

- Mining

- Construction

- Pharmaceuticals

- Automobile

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!