ASTM A213 T9, T12 ALLOY STEEL FINNED TUBE FOR HEATER EXCANGER

Fin tubes are a type of heat exchanger that is used in many different industries. These tubes have a finned surface, which increases their surface area and allows them to transfer heat more efficiently. This makes them ideal for applications where high heat transfer rates are required, such as in power plants and refrigeration systems.

The important features of this configuration are Efficiency, effective bond of fins to tubes under all conditions of temperature and pressure, and ability to withstand high fin side temperatures. This serrated fin configuration is even better to withstand the fin fouling if that is a problem in the application. This gives better heat transfer properties compared to solid fins.

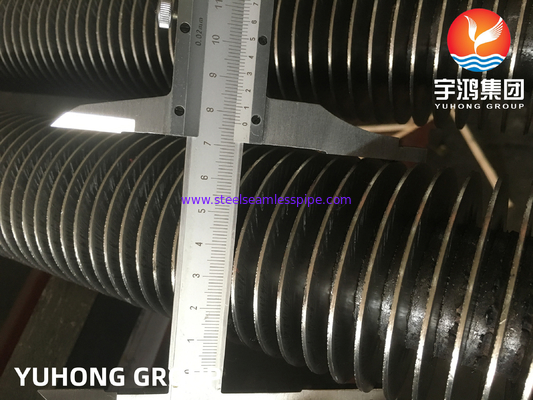

Helical Solid Finned Tubes are manufacturer by helically wrapping continuous fin strip on tube. HF Resistance Welding Usually Employs Frequency Of 400 kHz. The fin wound around the tube And Continuous weld. The fin strip is wounded spirally onto the tube and welded continuously with a high frequency electrical process to the base tube along the spiral root. The fin strip held under tension and confined laterally as it is formed around the tube, thereby ensuring that the strip is in forceful contact with the base tube surface. A continuous weld is applied at the point where the fin strip first begins to bend around the tube diameter, using the gas metal arc welding process.

For a given tube or pipe size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height, fin thickness and /or number of fins per meter of length.

HFW Solid Finned Tube

This welded steel finned tube configuration can be used for any practically heat exchanger application, and is particularly suited to high temperature and high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond.

Technical Details/Base Tube Details

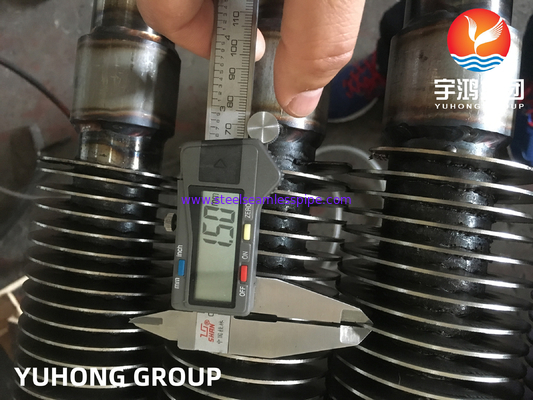

Tube Diameter : 20 mm OD Min to 219 mm OD Max.

Tube Thickness : Minimum 2 mm up to 16mm

Tube Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, CK 20 material and some other material.

Fin Details

Fins Thickness : Min. 0.8 mm to Max. 4 mm

Fins Height : Min 0.25” (6.35 mm) To Max.1.5” (38 mm)

Fin Density : Min 43 Fins Per Meter To Max. 287 Fins Per Meter

Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, Duplex Steel and Incolloy.

For a rapid quotation, plz send with following requirement:

Number of pieces,

base tube: Diameter, thickness, length and material specification.

Fins: material specification, type (solid or serrated), height, thickness, spacing, finned length and unfinned sections. Weld prep details if required.

Delivery period required.

Keywords: Fin tubes, Finned tube, Finned Pipe Helical Finned Tubes, Solid fin tubes, Serrated finned tube, Helical Serrated Finned Tubes, Tubos Aletados

| *These are the most common fin/tube patterns. We have more than 20 different plate fin and tube combinations. Contact me for more information and options. |

Helical Fin Surface

(Tube OD – Available Helical Fin Height on the Tube) |

| 5/8″ – 3/8″, 1/2″ and 7/16″ |

1″ – 3/8″, 1/2″ , 7/16″ and 5/8″ |

1 1/4″ – 3/8″, 1/2″ , 7/16″ and 5/8″ |

| 15.875mm – 9.525mm, 12.7mm and 11.113mm |

25.4mm – 9.525mm, 12.7mm, 11.113mm and 15.875mm |

31.75mm – 9.525mm, 12.7mm, 11.113mm, and 15.875mm |

- “L” Footed, Embedded and other helical fin attachment options are available.

- Contact me about the availability of 1 1/4″ (31.75mm) tube material

-

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!