KL TYPE WOULD FIN TUBE ASTM A312 TP304 BASE TUBE ALUMINUM 1060

What is KL Fin Tube?

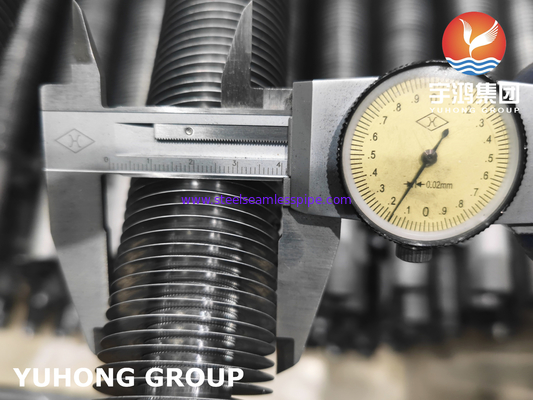

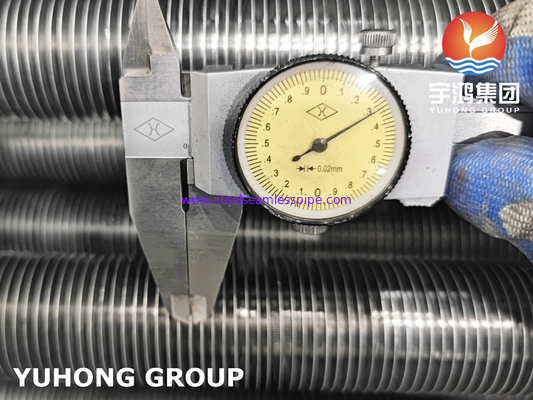

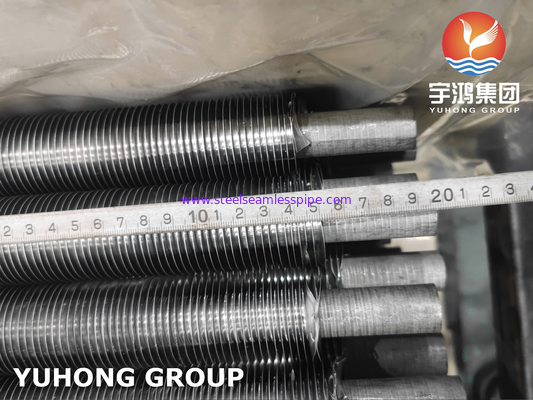

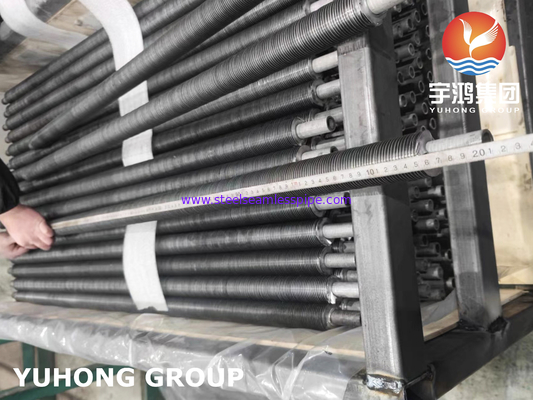

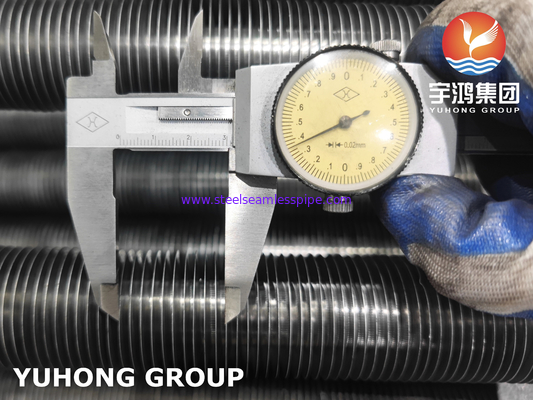

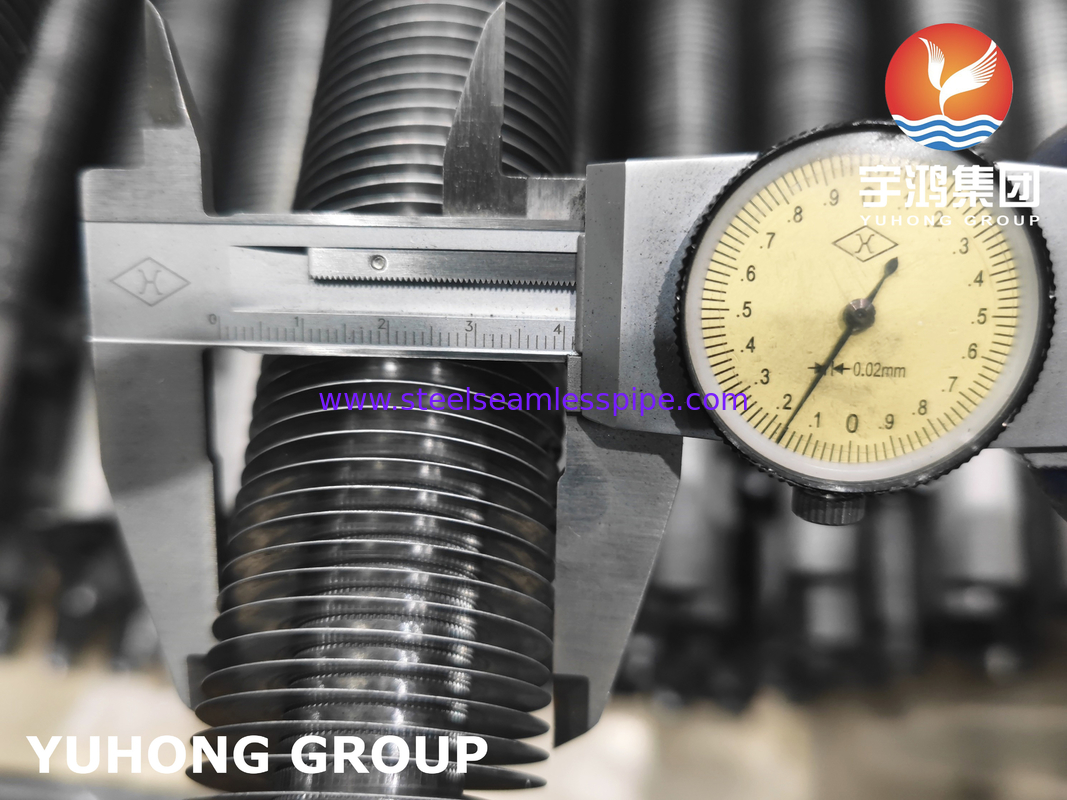

"KL" Fin Tubes are also called knurled finned tubes. The fin is wrapped around the tube and the foot is rolled into the outer surface of the pre knurled tube and secured at each end. The fins are manufactured from a strip of metal which is machined into an accurately controlled L shape foot, similar to the L type fin, then it is rolled into a taper causing it to curl. The tube surface is knurled by a rotating tool, then the foot of the fin is knurled into the base tube providing a tight bond that optimizes thermal transfer.

Knmurled fined ubes is bascll idienticalto the Wirap-On fin and produced with a combination of Wrap-oOn and Embedded.The fins are manufactured fromstrp which is preforned into an acurately controlled L shae similar to the L type, rolled nto a taper which causes it to kmurled.Then contimously helicallywound under tension onto the tube. The fin wrapped around the tube. The base tutbe is knurled by a rotating tool, then the foot of the fin is knurled into thebase tube, which provide a tight bond with increased thermal performance. Providing the correct fin strip is used the foot of one fin buttsup against the nextfin and there is no gap betweet the fios.This gives some corosion protecion to the tube.The fins are secured at each end to prevent unwinding in a similarway as L fins.

What is the advantage of Steel-aluminum fin tube?

The steel-aluminum finned tube has the basic characteristics of tight combination, low thermal resistance, good heat transfer function, high strength, small flow loss, non-deformation under long-term cold and hot conditions, and strong corrosion resistance, which improves the heat transfer efficiency of the overall radiator.

The steel-aluminum finned tube has the advantages of smooth surface, no burr, wrinkle, easy cleaning, no dust and scaling, and can maintain good heat transfer performance for a long time. The pressure bearing capacity of steel-aluminum finned tube can reach 0.8Mpa, which can not be borne by the gas radiator. The temperature of the medium in the tube can reach 130 degrees. It is the choice of heat dissipation device in large areas. Its service life is up to 20 years, and it is more e and reliable to use.

Advantages of Fin tube:

- Increase Heat Transfer Rate

A finned tube exchanger typically has tubes with fins attached to the outside. Usually, there will be some liquid flowing through the inside of the tubes and air or some other gas flowing outside the tubes, where the additional heat transfer surface area due to the finned tube increases the heat transfer rate. In a crossflow fin tube exchanger, the fins will typically be radial fins and they’ll either be circular or square in shape.

Improve Heat Transfer Coefficient

By not using a finned tube, the outside surface area is not significantly greater than the inside surface area. Because of this, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of the fluid outside the tube, the overall heat transfer rate can be greatly improved by increasing the outside surface area of the tube.

Increase Outside Surface Area

By having a finned tube in place, it increases the overall heat transfer rate. Finned tubes increase the outside surface area. This decreases the total number of tubes required for a given application which then also reduces overall equipment size and can in the long-run decrease the cost of the project.

Chemical Composition of SS304

Element | % Present |

|---|

Carbon (C) | 0.07 |

Chromium (Cr) | 17.50 - 19.50 |

Manganese (Mn) | 2.00 |

Silicon (Si) | 1.00 |

Phosphorous (P) | 0.045 |

Sulphur (S) | 0.015b) |

Nickel (Ni) | 8.00 - 10.50 |

Nitrogen (N) | 0.10 |

Iron (Fe) | Balance |

Mechanical properties of SS304

Property | Value |

|---|

Comprehensive Strength | 210 MPa |

Proof Stress | 210 Min MPa |

Tensile Strength | 520 - 720 MPa |

Elongation | 45 Min% |

Physical Properties of SS304

Property | Value |

|---|

Density | 8,000 Kg/m3 |

Melting Point | 1450 °C |

Thermal Expansion | 17.2 x 10-6 /K |

Modulus of Elasticity | 193 GPa |

Thermal Conductivity | 16.2W/m.K |

Electrical Resistivity | 0.072 x 10-6 Ω .m |

Applications:

- diesel charge air coolers

- oil coolers

- hydrogen coolers

- waste heat recovery

- driers

- air conditioning

- air heaters

- steam condensers

- generator coolers

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!