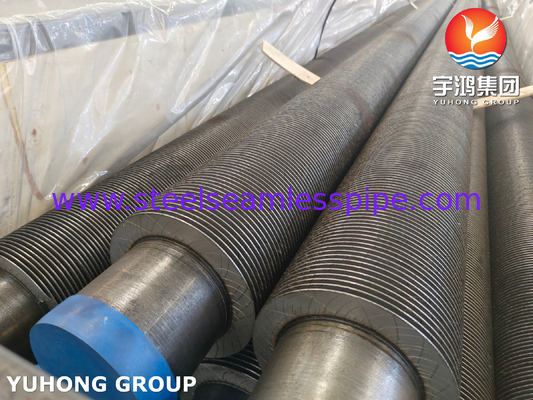

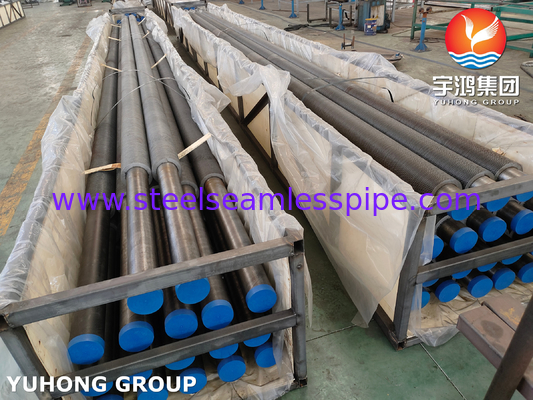

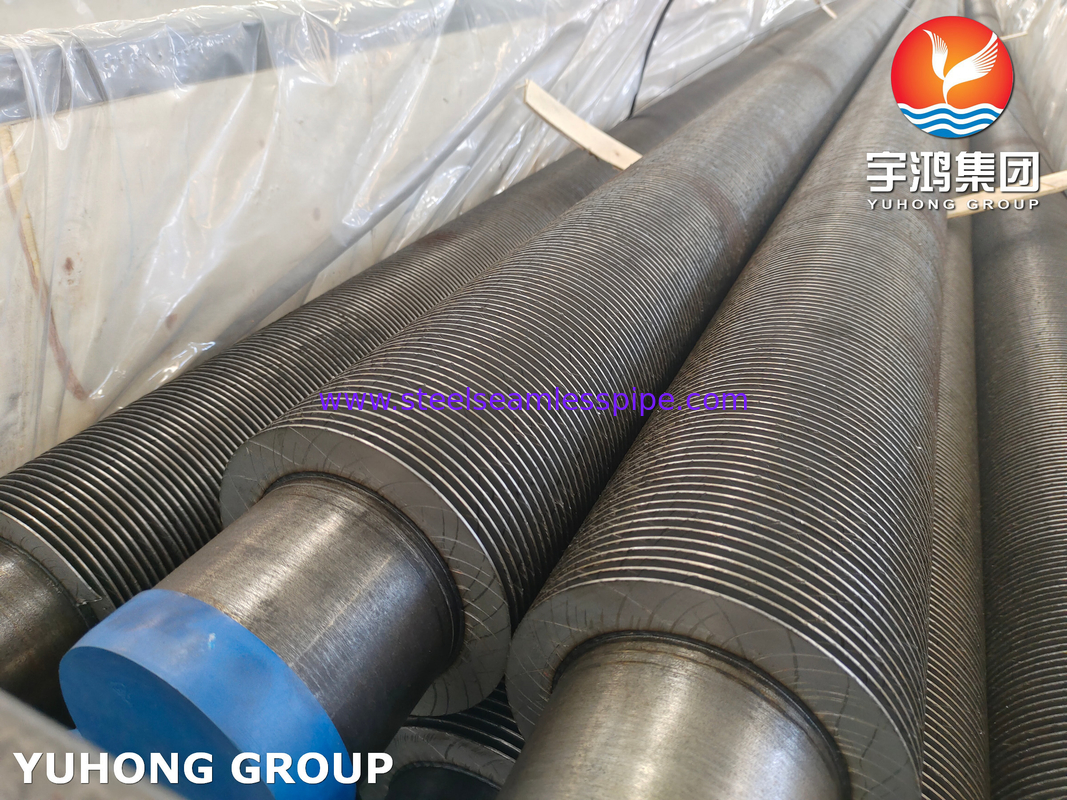

ASTM A106 Gr. B Carbon Steel High Frequency Welded / HFW Solid Finned Tube

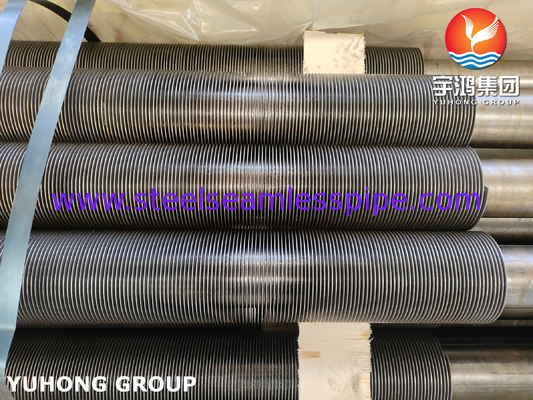

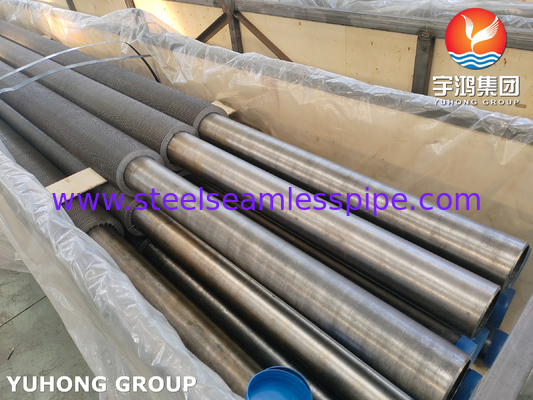

High Frequency Welded /HFW fin tube also called solid type fin tube, use steel or stainless steel strip directly welded to tube surface by HFW. It can improve heat transfer efficiency much more than bare tube. Due to the tight welding of the fins to the base tube, these finned tubes are often used in vibrating conditions. Fin type have Serrated fin and flat fin.

For a rapid quotation, plz send with following requirement:

Number of pieces,

base tube: Diameter, thickness, length and material specification.

Fins: material specification, type (solid or serrated), height, thickness, spacing, finned length and unfinned sections.

A106 Grade B Pipes Chemical Material Composition

|

|

Grade A

|

Grade B

|

Grade C

|

| Carbon max. % |

0.25 |

0.30 |

0.35 |

| Manganese % |

0.27 to 0.93 |

0.29 to 1.06 |

0.29 to 1.06 |

| Phosporous, max. % |

0.025 |

0.025 |

0.025 |

| Sulfur, max. % |

0.025 |

0.025 |

0.025 |

| Silicon, min. % |

0.10 |

0.10 |

0.10 |

Mechanical Properties of Carbon Steel Seamless Pipe ASTM A106

| Grade |

Yield Strength |

Tensile Strength |

| A106 Gr.B |

240 |

415 |

Base tube material:

stainless steel, carbon steel, alloy steel

ASME SA213/ASTM A213 TP304/304L TP316/TP316L TP321 TP310S TP317,

ASME SA106/ASTM A106 Gr B Gr C,ASME SA179/ASTM A179,ASME SA192/ASTM A192

Fin material:

Alloy steel, Stainless steel High Frequency Welded fins tube, carbon steel High Frequency Welded fins tube Duplex High Frequency Welded fins tube super duplex High Frequency Welded fins tube Air cooler fins tube, Air preheater fins tube.

Extruded fins tube Serrated fin tubes L Type fins tube G Type fins tube LL Type fins tube H Type fins tube KL Type fins tube HFW fin tube laser welded fin tube.

Advantages of high-frequency welded finned tubes

1. The installation is simple and economical. The length of high-frequency welding spiral finned tube can reach 6m, reducing the connection points, making the installation economical and fast, and reducing the probability of water leakage at the connection.

2. The maintenance is simple. After the installation of high-frequency welding spiral finned tube, the maintenance is basically unnecessary.

3. High efficiency. High frequency welding of spiral finned tube is the full contact welding between fins and steel pipes. The heat dissipation area is more than 8 times that of smooth tube. The internal is smooth and the internal water flow resistance is small.

4. Long service life, high mechanical strength of the combination of fins and pipes, and tensile strength of more than 200Mpa. The inside and outside of the pipes are all hot-dip galvanized.

Application of Finned Tube in Industries

- Petroleum Industry

- Chemical industry

- Wood industry

- Food industry

- Steel Industry

- Plastic molding industry

- Glycol dehydration units

- Coils for hybrid cooling towers

- Printing Machines

- Production of surface coatings

- Solvent recovery

- Cooling of turbine air intakes

- Textile production

- Greenhouse heaters and breeding

- Tanneries

- Anti-freeze coils for process air

- Paper works

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!