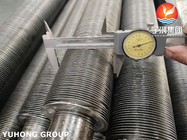

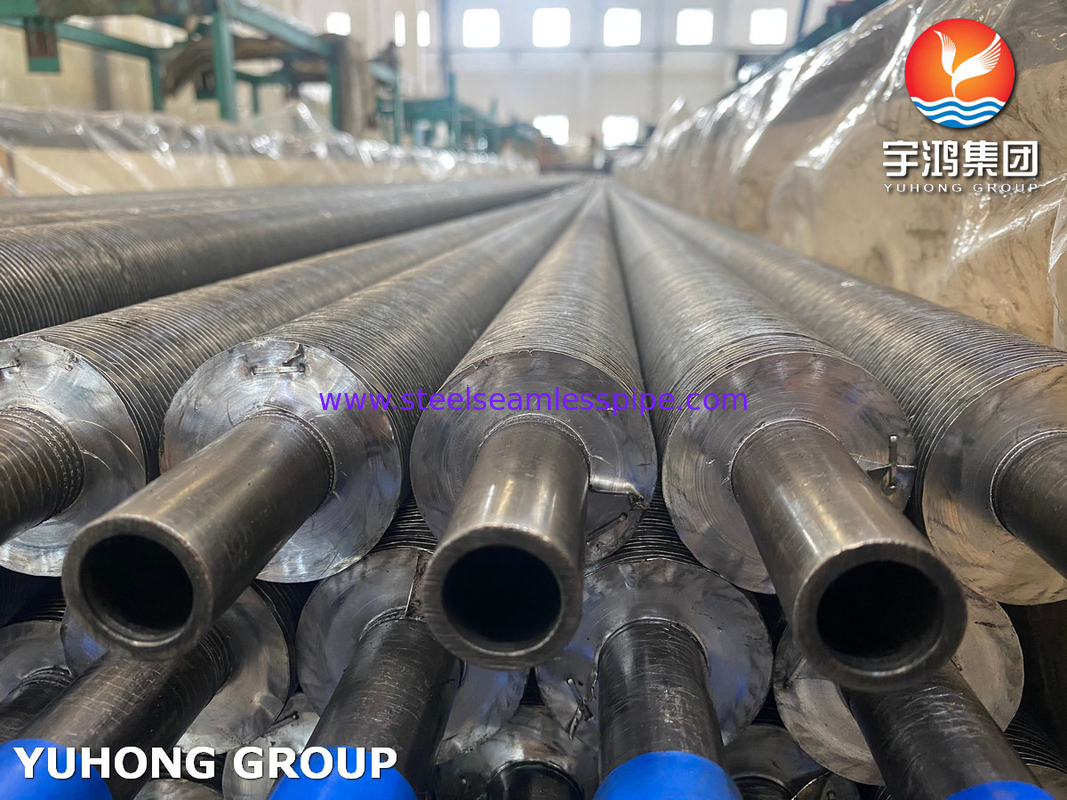

Carbon Steel ASTM A179 with A1060 G Type Embedded Finned Tube Heat Exchanger Tube

ASTM A179 Embedded G Type Finned Tube is a type of heat exchanger tube where the fins are embedded into the wall of the tube. It is designed to provide a larger surface area for heat transfer, which can improve the efficiency of the heat.

The "G" refers to the geometry of the fins, which are embedded in the tube wall itself rather than being externally attached exchanger. G fin tubes can withstand higher temperatures and pressures due to the stronger bond between the fin and the tube, resulting in improved thermal performance and durability. This fin type may be used in various industrial applications where efficient heat transfer is required, such as in power plants, chemical plants, and refineries.

Materials

G Type Embedded Finned Tube is combined with two different materials, including core tube grade and fin grade.

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L/316Ti, A789 S31803/S2205

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

Fin material: Aluminum (Alu.1100, Alu.1060), Copper, Steel

ASTM A179 TUBES SPECIFICATIONS

| Standards |

ASTM, ASME and API |

| Tueb Size |

20mm to 219mm OD |

| Tube Thickness |

2mm to 16mm |

| Schedules |

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Tolerance |

Cold drawn pipe: +/-0.1mm Cold rolled pipe: +/-0.05mm |

| Craft |

Cold rolled and Cold drawn |

| Type |

Seamless / ERW / Welded / Fabricated |

| Form |

Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| Length |

Min 3 Meters, Max18 Meters, or according to customer’s requirement |

| End |

Plain End, Beveled End, Treaded |

Chemical Components (%) of ASTM A179 Embedded Finned Tubes

| C |

Si |

Mn |

P |

S |

Mo |

Cr |

V |

| 0.06-0.18 |

/ |

0.27-0.63 |

≤0.035 |

≤0.035 |

/ |

/ |

/ |

Mechanical properties of ASTM A179 Embedded Finned Tubes

| Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(%) |

Hardness(HRB) |

| 325 Min |

180 Min |

35 Min |

72 max |

Features

- Dimensional accuracy

- High strength

- Durable

- Corrosion resistance

- Fine finish

Inspection and Tests Performed

Chemical Composition inspection, Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), Surface and Dimension Test, No-destructive Test, Hydrostatic Test

Some key benefits of G type embedded fin tubes include:

- Enhanced heat transfer efficiency: The fins increase the surface area available for heat transfer, leading to improved efficiency.

- Increased thermal performance: The embedded fins help in maintaining a more uniform temperature distribution, optimizing heat transfer processes.

- Improved strength and durability: The integrated fins provide mechanical strength and robustness to the overall tube construction.

- Resistance to corrosion: The fin-tube bonding minimizes the risk of corrosion and ensures a longer operational life.

Types of ASTM A179 Finned Tube for Heat Exchanger

- ASTM A179 L Type Finned Tube

- ASTM A179 LL Type Finned Tube

- ASTM A179 KL Type Finned Tube

- ASTM A179 G Type Finned Tube

- ASTM A179 H Type Finned Tube

- ASTM A179 Extruded Type Finned Tube

- ASTM A179 HF Finned Tube

- ASTM A179 Elliptical Finned Tube

- ASTM A179 Stud Finned Tube

- ASTM A179 Serrated Finned Tube

- ASTM A179 U Bending Low Finned Tube

- ASTM A179 Crimped Finned Tube

- ASTM A179 Inner Grooved Finned Tube

- ASTM A179 Longitudinal Finned Tube

Applications

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!