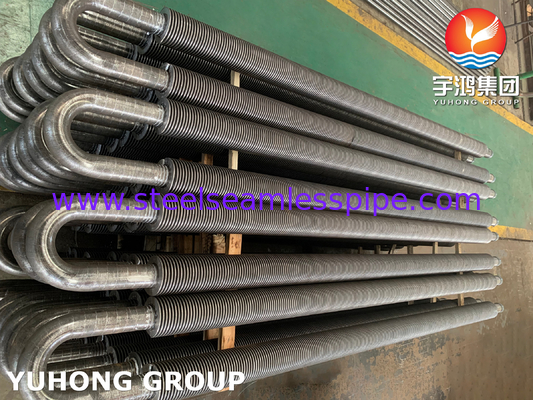

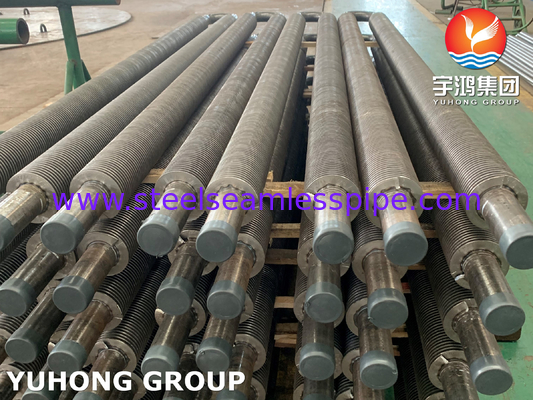

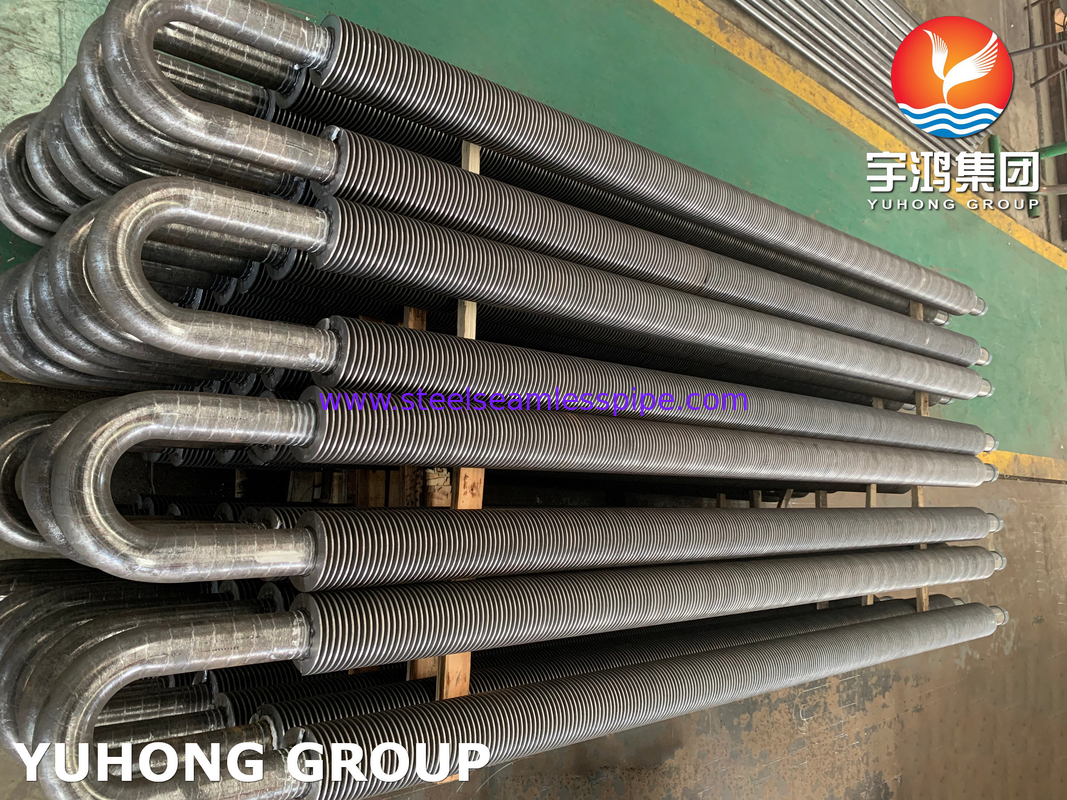

ASTM A106 GR.B Carbon Steel U Bend High Frequency Welded Fin Tube

What is high-frequency welded finned tube?

As the main heat dissipation component, high-frequency welded spiral finned tubes have excellent heat dissipation, which is several times or even dozens of times that of ordinary light tube radiators. They have excellent heat dissipation effects and are widely used in various fields and large areas. The service life of spiral wound tube radiators is generally 30 years. If the user maintains it correctly and excellently during use, its service life can be extended to as long as 50 years.

Advantages and applications:

High frequency welded finned tubes can meet the indoor heat demand. High frequency welded finned tubes have a wide range of applications, strong adaptability, and can be used for heat dissipation and heating in various fields. High frequency welded finned tubes have high flexibility and adaptability. It can be used for heating in various fields and places, and has been widely used in industries, agriculture, and other fields. In the industrial field, it is usually used in large workshop buildings, and the types and sizes of radiators applicable to different workshop buildings vary.

Fin Tube Specification

| PRODUCT |

TYPE |

NAME |

BARE TUBE MATERIAL |

FIN MATERIAL |

|

Heat Exchanger

Finned

Tube

|

EMBEDDED |

G-TYPE FIN TUBE |

CARBON STEEL, COPPER, STAINLESS STEEL, ALLOY |

ALUMINUM |

| EXTRUDED |

SINGLE METAL GOMBINED METAL |

CARBON STEEL, COPPER, STAINLESS STEEL, ALLOY |

COPPER, ALUMINUM |

|

LOW FIN TUBE

T-TYPE FIN TUBE

|

CARBON STEEL, COPPER, STAINLESS STEEL, ALLOY |

/ |

|

BAMBOO TUBE

CORRUGATED TUBE

|

CARBON STEEL, COPPER, STAINLESS STEEL, ALLOY |

/ |

| WOUND |

L/KL/LL TYPE FIN TUBE |

CARBON STEEL, COPPER, STAINLESS STEEL, ALLOY |

COPPER,ALUMINUM |

| STRING |

STRING FIN TUBE |

ALUMINUM, COPPER, CARBON STEEL, STAINLESS STEL |

ALUMINUM, COPPER, CARBON STEEL, STAINLESS STEL |

| U-TYPE |

U-TYPE TUBE |

CARBON STEEL, COPPER, STAINLESS STEEL |

/ |

| WELDING |

HF WELDING FIN TUBE |

CARBON STEEL, STAINLESS STEEL, ALLOY |

CARBON STEEL, STAINLESS STEEL, ALLOY |

| U-TYPE |

H/HH TYPE FIN TUBE |

CARBON STEEL, STAINLESS STEEL, ALLOY |

CARBON STEEL, STAINLESS STEEL, ALLOY |

| WELDING |

STUDDED FIN TUBE |

CARBON STEEL, STAINLESS STEEL, ALLOY |

CARBON STEEL, STAINLESS STEEL, ALLOY |

Base tube material:

stainless steel, carbon steel, alloy steel

ASME SA213/ASTM A213 TP304/304L TP316/TP316L TP321 TP310S TP317,

ASME SA106/ASTM A106 Gr B Gr C,ASME SA179/ASTM A179,ASME SA192/ASTM A192

Alloy Steel Chemical Compositions

| Grade |

UNS Designation |

Composition (%) |

| Carbon |

Manganese |

Phosphorus, max |

Sulfur, max |

Silicon |

Chromium |

Molybdenum |

| P1 |

K11522 |

0.10-0.20 |

0.30-0.80 |

0.025 |

0.025 |

0.10-0.50 |

-- |

0.44-0.65 |

| P2 |

K11547 |

0.10-0.20 |

0.30-0.61 |

0.025 |

0.025 |

0.10-0.30 |

0.50-0.81 |

0.44-0.65 |

| P5 |

K41545 |

0.15MAX |

0.30-0.60 |

0.025 |

0.025 |

0.50MAX |

4.00-6.00 |

0.45-0.65 |

| P9 |

K90941 |

0.15MAX |

0.30-0.60 |

0.025 |

0.025 |

0.25-1.00 |

1.00-1.50 |

0.44-0.65 |

| P11 |

K11597 |

0.05-0.15 |

0.30-0.60 |

0.025 |

0.025 |

0.50-1.00 |

1.00-1.50 |

0.44-0.65 |

| P12 |

K11562 |

0.05-0.15 |

0.30-0.61 |

0.025 |

0.025 |

0.5MAX |

0.80-1.25 |

0.44-0.65 |

| P15 |

K11578 |

0.05-0.15 |

0..30-0.60 |

0.025 |

0.025 |

1.15-1.65 |

-- |

0.44-0.65 |

| P21 |

K31545 |

0.05-0.15 |

0.30-0.60 |

0.025 |

0.025 |

0.50MAX |

2.65-3.35 |

0.80-1.06 |

Material Grade

| American Standard |

Austenitic Steel:

TP304,TP304L,TP304H, TP304N, TP310S,TP316,TP316L,TP316Ti,TP316H, TP317,TP317L, TP321, TP321H,TP347, TP347H,904L…

Duplex Steel :

S32101,S32205,S31803,S32304,S32750, S32760

Others:TP405,TP409, TP410, TP430, TP439,... |

| Europen Standard |

1.4301,1.4307,1.4948,1.4541,1.4878,1.4550,1.4401,1.4404,1.4571,1.4438, 1.4841,1.4845,1.4539,1.4162, 1.4462, 1.4362, 1.4410, 1.4501 |

| GOST |

08Х17Т,08Х13,12Х13,12Х17,15Х25Т,04Х18Н10,08Х20Н14С2, 08Х18Н12Б,10Х17Н13М2Т,10Х23Н18,08Х18Н10,08Х18Н10Т, 08Х18Н12Т,08Х17Н15М3Т,12Х18Н10Т,12Х18Н12Т,12Х18Н9, 17Х18Н9, 08Х22Н6Т, 06ХН28МДТ

|

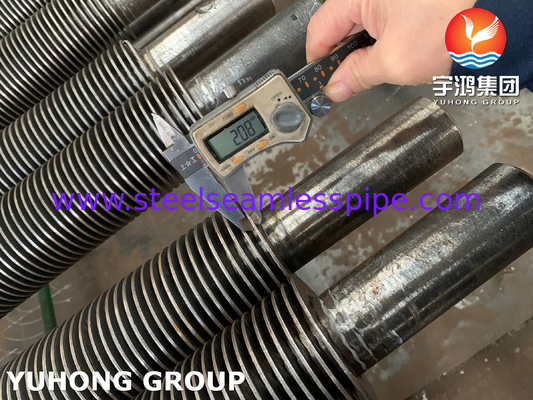

Technical Details/Base Tube Details

Tube Diameter : 20 mm OD Min to 219 mm OD Max.

Tube Thickness : Minimum 2 mm up to 16mm

Tube Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, CK 20 material and some other material.

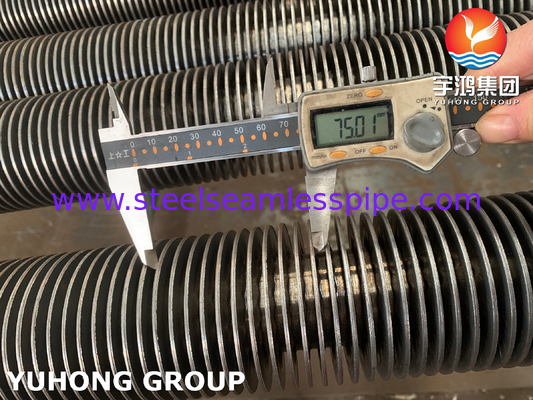

Fin Details

Fins Thickness : Min. 0.8 mm to Max. 4 mm

Fins Height : Min 0.25” (6.35 mm) To Max.1.5” (38 mm)

Fin Density : Min 43 Fins Per Meter To Max. 287 Fins Per Meter

Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, Duplex Steel and Incolloy.

Applications

Heat exchanger

Air-conditioner

Refrigerator

Economizer

Chemical / Petrochemical industries

Heat Industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!