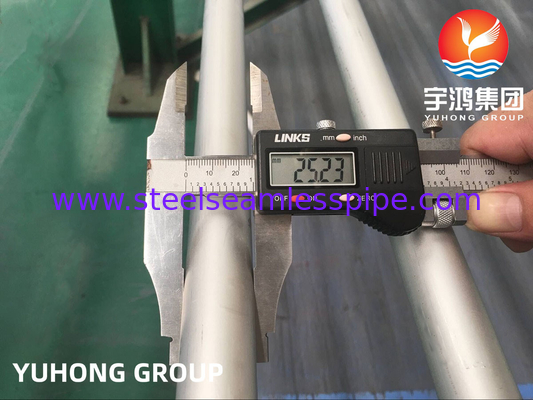

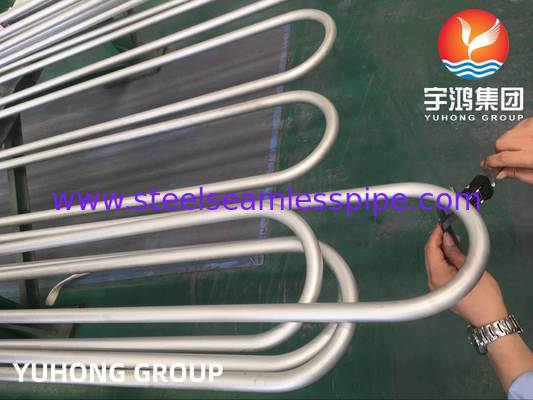

ASTM B444 Alloy 625 (UNS N06625) Seamless U Bend Tube Heat Exchanger Tube

N06625 Alloy Steel Heat Exchanger Tube metallographic structure:

The microstructure of this alloy in the solid solution state is an austenitic matrix with a small amount of TiN, NbC, and M6C phases. After long-term aging at 650~900 ℃, the precipitated phases are γ',δ, M23C6 and M6C.

N06625 Alloy Steel Heat Exchanger Tube Process Performance and Requirements:

1. This alloy has good cold and hot formability, and the heating temperature for forging steel ingots is 1120 ℃.

2. The average grain size of this alloy is closely related to the degree of deformation of the forging and the final forging temperature.

3. The welding performance of the alloy is good, and it can be used for argon arc welding with tungsten electrode or this alloy as an additive in a protective atmosphere, as well as brazing and resistance seam welding.

4. Surface treatment process: To remove the oxide scale on the alloy surface, first alkali wash, and then acid wash in nitric acid, hydrofluoric acid aqueous solution.

5. When the processing amount of alloy is greater than 15% during cold working, annealing treatment shall be carried out after Hot working.

N06625 Alloy Steel Heat Exchanger Tube Application

1.Components of organic chemical processes containing chlorides, especially when using acidic chloride catalysts;

2.Cooking and bleaching tanks used in the pulp and paper industry;

3.The absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, guide plate, and flue in the flue gas desulfurization system;

4.Used to manufacture equipment and components for sour gas environment;Acetic acid and acetic anhydride reaction generator;Sulfuric acid condenser, etc.

N06625 Alloy Steel Heat Exchanger Tube Main specifications:

N06625 seamless pipe, N06625 steel plate, N06625 round steel, N06625 forging, N06625 flange, N06625 ring, N06625 welded pipe, N06625 steel strip, N06625 straight bar, N06625 wire and supporting welding materials, N06625 round cake, N06625 flat steel, N06625 hexagonal bar, N06625 large and small head, N06625 elbow, N06625 tee, N06625 machined part, N06625 bolt and nut, N06625 fastener

Chemical Composition of UNS N06625 / Inconel 625 Heat Exchanger Tube

| C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

Cu |

Co |

Cb Ta |

Ti |

Al |

Fe |

Nb |

Other |

| 0.1 |

.50 max |

.015 max |

.015 max |

.50 max |

20.0 -23.0 |

58.0 min |

8.0 -10.0 |

|

1.0 max |

|

0.40 max |

0.40 max |

5.0 max |

3.15 -4.15 |

|

Mechanical Properties of ASTM B444 Inconel 625 Alloy Steel Heat Exchanger Tube

Typical room temperature Tensile Properties of Annealed Material (Representative Tensile Properties, bar, 1800° F anneal)

| Temp° F |

Tensile (psi) |

.2% Yield (psi) |

Elongation in 2 “ (%) |

| 70 |

144,000 |

84,000 |

44 |

| 400 |

134,000 |

66,000 |

45 |

| 600 |

132,000 |

63,000 |

42.5 |

| 800 |

131,500 |

61,000 |

45 |

| 1000 |

130,000 |

60,500 |

48 |

| 1200 |

119,000 |

60,000 |

34 |

| 1400 |

78,000 |

58,500 |

59 |

| 1600 |

40,000 |

39,000 |

117 |

Specifications

| International Specifications |

Sheet/Plate |

Round Bar |

Pipe |

Tube |

Fittings |

Forgings |

| BS 3072, BS 3074, BS 3076, NA 21 DIN 17744, DIN 17750, DIN 17751, DIN 17752, DIN 17754. Werkstoff Nr. 2.4856 AFNOR NC 22 D Nb |

ASME SB-443 AMS 5599 AMS 5869 |

ASME SB-446 AMS 5666 AMS 5837 |

ASME SB-444 ASME SB-829 ASME SB-775 ASME SB-705 |

ASME SB-444 ASME SB-829 ASME SB-751 ASME SB-704 AMS 5581 |

ASME SB- 366 |

ASME SB- 564 AMS 5666 |

| Alloy |

Alloy 200(N02200), Alloy 201(N02201), Alloy 20(N08020), Alloy 28(N08028), Alloy 31(N08031), Alloy 36 (K93600), Alloy 904(N08904) |

| Hastelloy |

Hastelloy C22(N06022), Hastelloy C276(N10276), Hastelloy C4(N06045), Hastelloy S(N06635), Hastelloy C2000(N06200), Hastelloy G-30(N06030), Hastelloy G-35(N06035), Hastelloy X(N06002), Hastelloy N(N10003), Hastelloy B(N10001), Hastelloy B-2(N10665), Hastelloy B-3(N10675) |

| Monel |

Monel 400(N04400), Monel 401 (N04401), Monel 404 (N04404), Monel K500(N05500) |

| Inconel |

Inconel 600(N06600), Inconel 601(N06601), Inconel 617(N06617), Inconel 625(N06625), Inconel 690(N06690), Inconel 718(N07718), Inconel X-750(N07750) |

| Incoloy |

Incoloy 800(N08800), Incoloy 800H(N08810), Incoloy 800HT(N08811), Incoloy 825(N08825), Incoloy 925(N08925), Incoloy 926(N09926) |

| Others |

253MA(S30815), 254SMO(S31254), S32304, 17-4PH(S17400), 17-7PH(S17700), 15-7PH(S15700) |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!