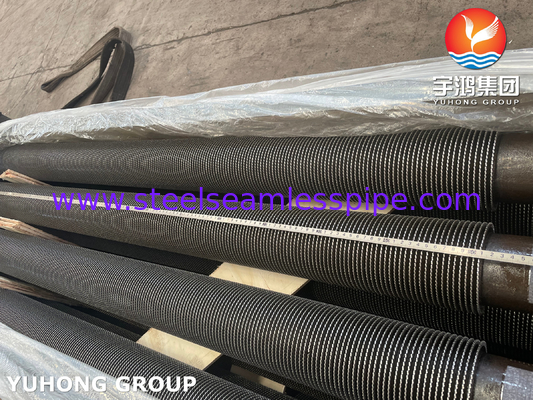

HFW Helical Spiral Serrated Finned Tube For Radiator Heat Exchanger

Overview

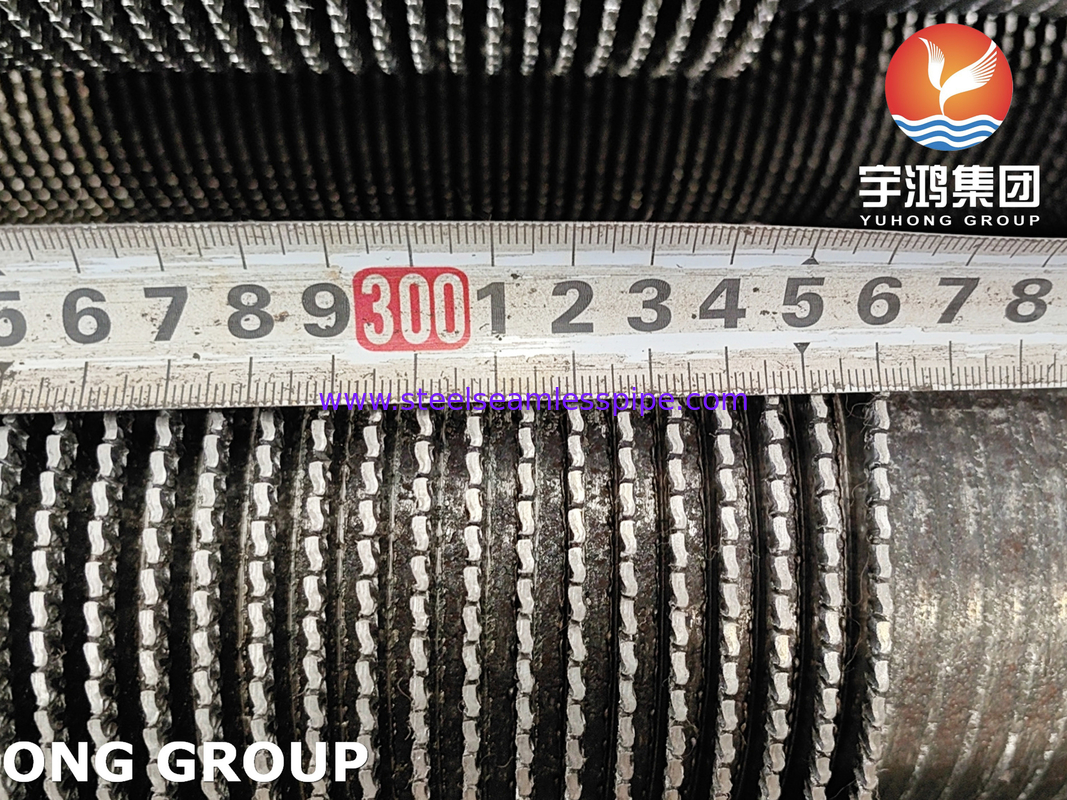

Yuhong Group's Welded Helical Serrated Finned Tubes are produced in the same manner as solid fin, except that before the fin strip is formed around the tube, the fin strip is cut (or “serrated”) crosswise from one edge (which will become the outer edge of the fin segments) to within 1/4″ of the other edge, leaving an uncut portion that will become a continuous base for the fin segments. The interval between cuts (which determines the segment width after the strip is formed around the tube) may be specified as either 5/32″ or 5/16″. After being cut, the fin strip is held under tension and confined laterally as it is formed around the tube, thereby ensuring forceful contact with the tube surface. As the fin strip is formed around the tube its outer (serrated) edge spreads, opening the segments like petals of a daisy. A continuous weld is applied at the point where the fin strip first begins to bend around the tube diameter using Yuhong Group's unique gas metal arc welding (GMAW) process. This welding process creates the strongest fin to tube attachment in the industry, excellent heat transfer characteristics, low fin-side pressure drop and little to no change in grain microstructure and physical characteristics even when 3%-9% chromium tubes are used.

Finned tubes are classified according to their shape:

- Square finned tube;

- Circular finned tube;

- Spiral finned tube;

- Longitudinal Finned Tube

- Corrugated finned tubes;

- Helical Serrated Finned Tubes;

- Needle shaped finned tube;

- Integral plate shaped finned tube (plate fin);

- Inner finned tube. Wait a minute.

Finned tubes are classified by processing technology:

- Rolled finned tube;

- Welded formed fin tube (welded fin tube, Submerged arc welding fin tube);

- Rolling formed finned tubes;

- Set shaped finned tubes;

- Casting finned tubes;

- Tension wound finned tube;

- Insert tube.

| Yuhong Group's Welded Helical Serrated Finned Tubes |

| Weld Process |

GMAW |

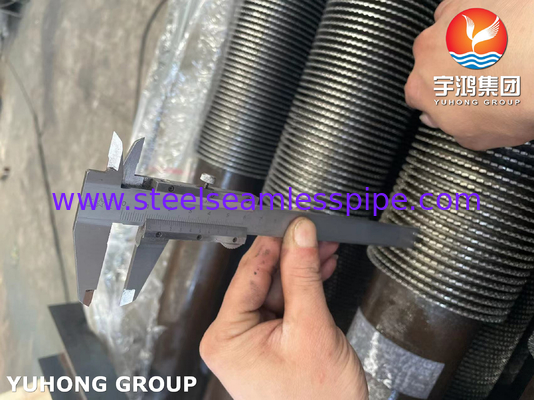

| Tube/Pipe Size |

1.00″ to 12.75″ outside diameter |

| Fin Height |

0.375″ to 1.25″ |

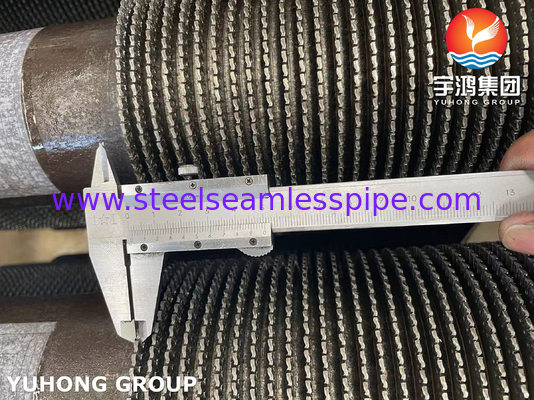

| Fin Segment Width |

5/32″ or 5/16″ |

| Fin Thickness |

20ga (.035″) to 16ga (.060″) |

| Fin Pitch |

1 to 7 fins per inch |

| Materials |

Any material combination that can be arc welded |

| Tube Length |

No practical limit |

Base pipe/tube material:

Stainless steel: ASME SA213/ASTM A213, ASME SA249/A249 ,ASME SA312/A312: TP304,304L, TP304H, TP310S, TP310H, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321,TP321H, TP347, TP347H, TP904L

Duplex/Super Duplex Steel: ASME SA789/A789 , ASME SA790/A790: S31803, S32205, S32750, S31500, S32304, S32900

Carbon Steel : ASME SA106/ASTM A106 Gr B, Gr C, ASME SA179/ASTM A179, ASME SA192/ASTM A192, ASTM A214, ASTM A210 Gr.A1 , Gr.C.

Alloy Steel : ASME SA213/ASTM A213 T1, T11, T12, T22, T23, T5, T9, T91, T92 ; ASME SA335 /ASTM A335 P1, P11, P12, P22, P23, P5, P9 , P91, P92 , 16Mo3, 15Mo3, 13CrMo-4, 12Cr1MoVG.

Nickel Alloy Steel Grade:Hestalloy:C-276, C-4, C-22, C-2000, X, B-2, B-3, G-30, G-35. Monel:400,401, 404, R-405, K500.

Inconel:600, 601, 617, 625, 690, 718, 740, X-750. Incoloy:800, 800H, 800HT, 825, 840.

Pure Nickel:Ni-200, Ni-201, Ni-270. NS Alloy:Ns 1101, NS1102, NS1103,NS3105. Copper Alloy Steel: ASTM B111(70400, C70600, C71500, C71640, C68700, C44300)

Fin material: Alloy Steel , Stainless Steel , Carbon Steel .

Stainless steel High Frequency Welded fins tube, carbon steel High Frequency Welded fins tube, Duplex High Frequency Welded fins tube Super Duplex High Frequency Welded fins tube, Air cooler fins tube, Air preheater fins tube. Extruded fins tube, Serrated fin tubes.

Advantage of HFW Fin Tube:

- 1. Because of the fast welding speed and the strong self-cooling effect of the welded parts, not only the heat-affected zone is small, but also the oxidation is not easy to occur, so the organization and performance of the weld is very good.

- 2. Low contact heat resistance, high stability, anti-dust accumulation ability.

- 3. Large heat exchange area.

- 4.The welded steel finned tube configuration can be used for any practically heat exchanger application, and is particularly suited to high temperature and high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

- 5. A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond.

- 6. High frequency welded helical spiral solid finned tube provide the designer with high thermal efficiency and compact design solutions for a whole range of heat exchangers where clean flue gases are used. Helical finned Tubes are manufactured in both Solid and Serrated type.

Application of HFW Fin Tube :

- Air Cooler

- Charge Air Chiller

- Condenser

- Evaporator

- Fluid Cooler

- Gas Cooler

- Oil Cooler

- Radiator

- Refrigeration

- Steam to Air Heat Exchanger

- superheater etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!