ASTM A179/ASME SA179 Carbon Steel U Bending Tube for Heat Exchanger ET/HT/PT

Overview

The ASTM A179 / ASME SA179 Seamless Tubes has similar grades and standards like ASTM A179/ A179M. It is viable in types like seamless / cold drawn / hot drawn etc. This tube product is available in custom-made size, diameter, and thickness. The Carbon Steel A179 Heat-Exchanger Tubes is strictly subjected to various tests in order to ensure the quality of the product. This grade of the tube is packed in wooden box or case in order to avoid external damage during the last stage of production. What's more, these tubes are used in various industrial applications and are available in market leading prices.

These Seamless Tube mainly find applications in Pressure Vessels, Cryogenic Pressure Vessels, High pressure Equipments, Tube Sheets of Heat Exchangers, Boilers, Air Pre Heater, Finned Tubes, Air Cooler Tubes, etc. They are used in Industries like Refineries, Power Plants, Steel Plants, Chemical Factories, Fertilizer plants, and Ship Building etc.

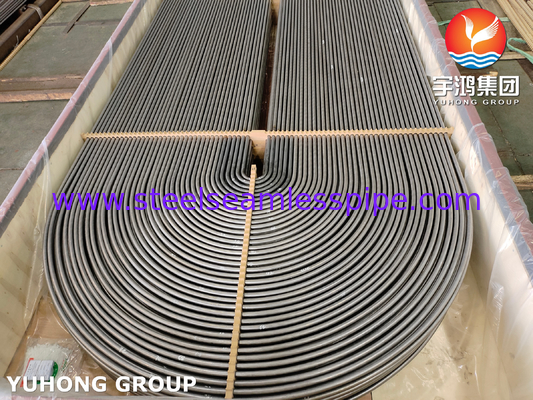

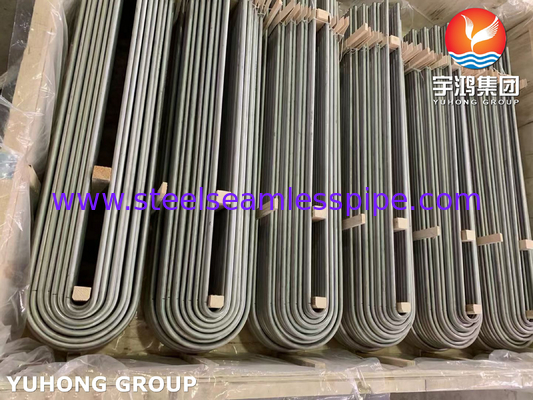

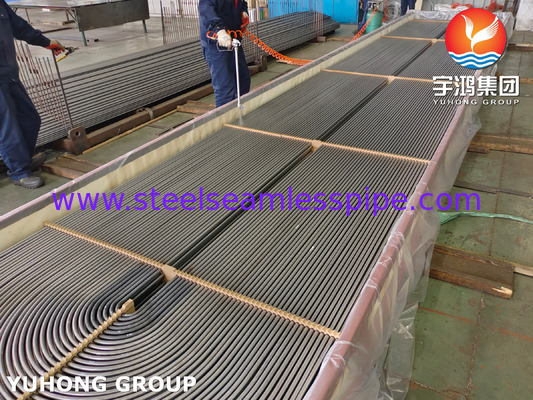

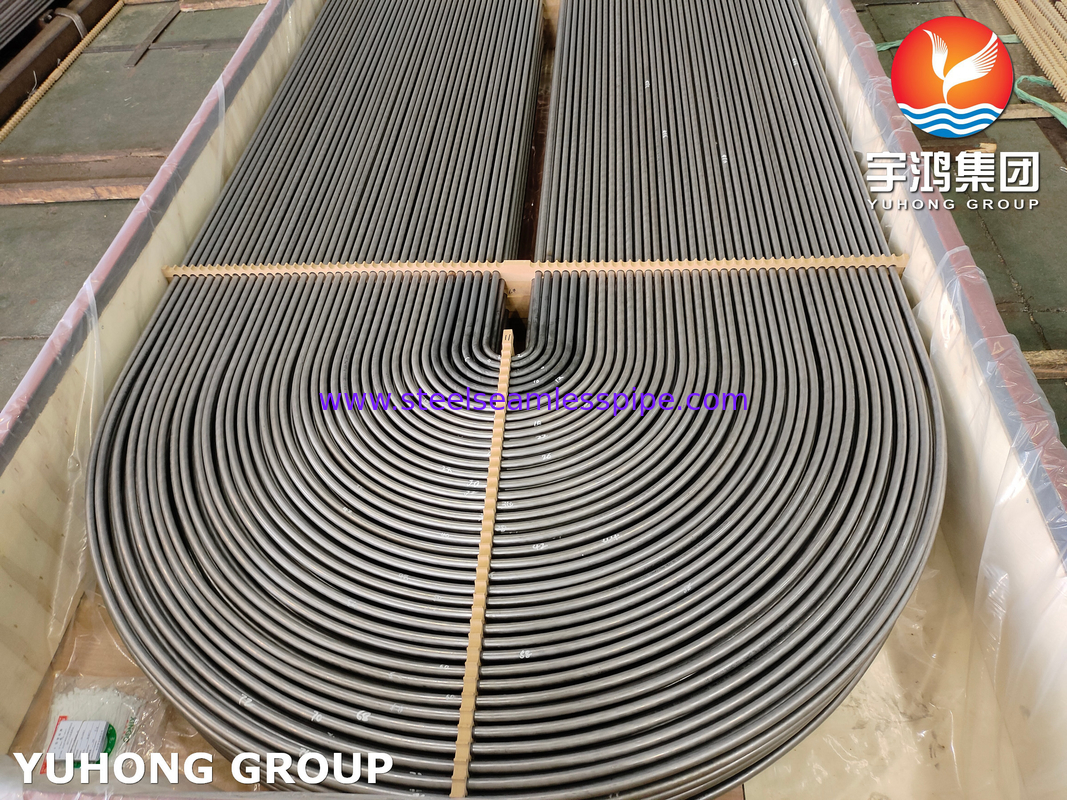

U Tubes are manufactured after the Straight Tubes are manufactured. The Bending is done in Cold State on an Automatic U Bending Machine. To ensure that wall thinning and diameter ovality are kept in control, bending of tubes Is done with a mandrel inserted in the tubes. Furthermore the U - Bend portion of the U-Tube is Stress Relieved in controlled conditions and cycle to give longer life.

The U bent tubes are finally 100% Tested for Hydrostatic Leak Test and then finally DP tested. These tubes are vulnerable to getting damaged in transit and hence are required to be handled with care. We ensure this by packing tubes in specially designed steel frames. These frames are fit into the wooden box o further ensure ety of the tubes.

ASTM A179/A179M U-bent tube Chemical Compositions

| ASTM A179/A179M Chemical Components (%) |

| C |

Si |

Mn |

P |

S |

Mo |

Cr |

V |

| 0.06-0.18 |

/ |

0.27-0.63 |

≤0.035 |

≤0.035 |

/ |

/ |

/ |

ASTM A179/A179M U-bent tube Mechanical Properties

| ASTM A179/A179M Mechanical properties |

Tensile

Strength (Mpa) |

Yield

Strength (Mpa) |

Elongation

(%) |

Hardness

(HRB) |

| ≥325 |

≥180 |

≥35 |

≤72 |

ASTM A179/A179M U-bent tube Wall Thickness Tolerance

| ASTM A179/A179M Seamless, Cold-Finished Tubes |

Outside Diameter

In. (mm) |

Wall thickness Tolerance % |

| Over (+) |

Under (-) |

1 ½ (38.1)

and under |

20 |

0 |

| Over 1½ (38.1) |

22 |

0 |

ASTM A179/A179M U-bent tube Outside Diameter Tolerance

| ASTM A179/A179M Cold-Finished Seamless Tubes |

Outside Diameter

In. (mm) |

Permissible Variations In. (mm) |

| Over (+) |

Under (-) |

| Under 1 (25.4) |

0.004 (0.1) |

0.004 (0.1) |

| 1 to 1 ½ (25.4 to 38.1), Incl |

0.006 (0.15) |

0.006 (0.15) |

| Over 11⁄2 to 2 [38.1 to 50.8], Excl |

0.008 (0.2) |

0.008 (0.2) |

| 2 to 21⁄2 [50.8 to 63.5], Excl |

0.010 (0.25) |

0.010 (0.25) |

| 21⁄2 to 3 [63.5 to 76.2], Excl |

0.012 (0.3) |

0.012 (0.3) |

ASTM A179/A179M Cut Length Tolerance

| ASTM A179/A179M Cold-Finished Seamless Tubes |

| Outside Diameter |

Cut Length, in.(mm) |

| In.(mm) |

Over (+) |

Under (-) |

| All Sizes |

3⁄16 [5] |

0 [0] |

| Under 2 [50.8] |

1⁄8 [3] |

0 [0] |

| 2 [50.8] and over |

3⁄16 [5] |

0 [0] |

| Under 2 [50.8] |

1⁄8 [3] |

0 [0] |

| 2 [50.8] and over |

3⁄16 [5] |

0 [0] |

| These permissible variations in length apply to tubes before bending. They apply to cut lengths up to and including 24 ft [7.3 m]. For lengths greater than 24 ft [7.3 m], the above over-tolerances shall be increased by 1⁄8 in. [3 mm] for each 10 ft [3 m] or fraction thereof over 24 ft or 1⁄2 in. [13 mm], whichever is the lesser. |

ASTM A179/A179M U-bent tube Hydrostatic Test Pressures

| ASTM A179/A179M Hydrostatic Test Pressures |

| Outside Diameter of Tube, in. [mm] |

Hydrostatic Test Pressure, psi [Mpa] |

| Under 1 [25.4] |

1000 [7] |

| 1 to 11⁄2 [25.4 to 38.1], excl |

1500 [10] |

| 11⁄2 to 2 [38.1 to 50.8], excl |

2000 [14] |

| 2 to 3 [50.8 to 76.2], excl |

2500 [17] |

ASTM A179/A179M U-bent tube sizes (u-bending, u-bend)

| Tube Outside Diameter |

Tube Wall Thickness |

Bending Radius |

U Tube Straight “Leg” Length |

Straight Tube Before U Bending |

| min. 12,70 mm |

min. 0,70 mm |

min. 1,5 x D |

max. 11 000 mm |

max. 24 000 mm |

| max. 31,75 mm |

max 5,16 mm |

max. 1 250 mm |

|

|

ASTM A179/A179M U-Bending tubes are widely used in Heat-exchangers.

ASTM A179/A179M U-bent tubes for heat exchangers applied mostly in oil and gas plants, chemical and petrochemical plants, refineries, power plants and renewable energy plants. Low fin tubes can be supplied in the form of U bends. Sizes tolerances of U bend tubes are to fullfil the requirements of: ASTM A556 /A556M and DIN 28179

ASTM A179/A179M U-bent tube heat treatment

Post bending heat treatment by electrical resistance (Joule effect) is applied. The temperature is monitored and controlled during the process. It is possible to perform the heat treatment in a nitrogen atmosphere.

ASTM A179/A179M U-bent tube test as follows

•Hydrostatic Test

•Air Underwater Test

•Pulsating Pressure Test

•Dye Penetrant Test

•Magnetooptical Test

ASTM A179/A179M U-bent tube bending Type:

Cold Bending and Hot Bending.

ASTM A179/A179M U-bent tube Heat Treatment:

After Cold Bending, the bending area needs heat treatment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!