ASME SA213 TP304 Extruded Fin Tube+ Al Fin for Economizer

Overview

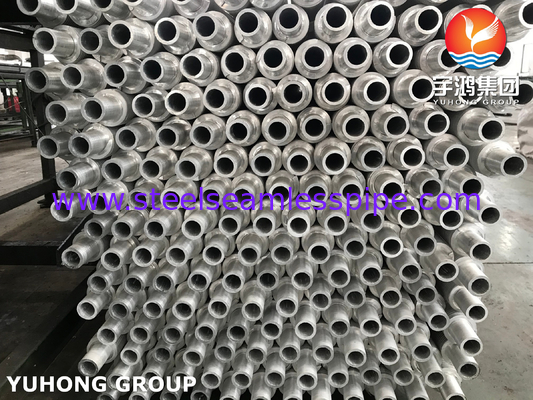

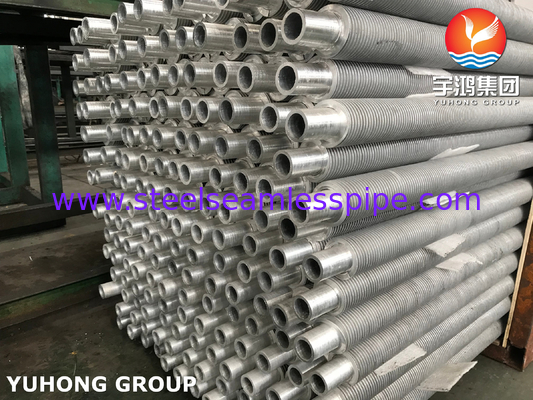

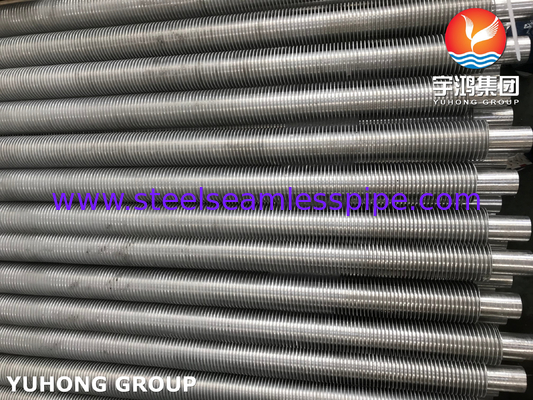

The steel-aluminum Extruded Type Finned Tube is a type of finned tube that is manufactured by combining aluminum and steel tubes through a bimetallic composite process. The fins are then formed through mechanical cold rolling.

There are two major types of finned tubes available: single metal tubes (also known as mono metallic fin tubes) and bimetallic tubes (composite extruded fin tubes). The single metal tubes are made of copper, aluminum, or copper nickel. The bimetallic tubes, on the other hand, have a core tube made of a harder material. The outer tube is rolled onto the core tube to ensure a tight bond and good thermal contact between the two tubes.

The finned tube has several advantages, including tightness, low heat resistance, good heat transfer performance, high strength, minimal flow losses, strong corrosion resistance, and resistance to deformation. It also has a long working lifetime in both cold and hot conditions. The overall rolling fin is smooth and does not have any burrs, making it easy to clean. The fin surface can be easily wet and cooled with water during heating and air conditioning engineering. In dry and heating situations, the fin surface is treated with anodizing, resulting in a beautiful color and luster while effectively preventing surface corrosion.

The aluminum rolling finned tube is made by rolling the aluminum tube as a whole. It offers advantages such as no contact thermal resistance, high strength, resistance to thermal shock and mechanical shock, good thermal performance, and a considerable expansion heat transfer surface. Heat exchangers using this type of finned tube outperform string or plate finned tubes.

Extruded serrated finned tube size and material:

| Extruded serrated finned tube size and material |

| Tube OD |

10~51 (mm) |

0.4”~2” |

| Tube Wall Thk |

1.65~3.0 (mm) |

0.065”~0.118” |

| Tube Length |

≤18,500 (mm) |

≤60.7 ft |

| Fin Thk |

0.3~1.2 (mm) |

0.012”~0.047” |

| Fin Height |

5~16 (mm) |

0.2”~0.63” |

| Fin Pitch |

100~555 (mm) |

3~14 FPI |

| Serrates |

12or 24 |

12 or 24 |

| Fin Type |

Extruded |

| Material Combinations |

| Fin Material |

Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) |

| Copper |

| Tube Material |

C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) |

| S.S. (most common grade: TP304, 316, 321, 347,A789) |

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) |

| Titanium (most common grade: B338Gr2) |

| Applied Temperature |

300°C |

| Type of Service |

Medium temperature, severe atmospheric corrosive environment.

|

Application of the Extruded Fin Tube

1. Heat pipes: These tubes are used in heat pipe systems for air-to-air heat exchangers in HVAC (Heating, Ventilation, and Air Conditioning) applications.

2. Air dehumidification: Extruded serrated finned tubes are used in air treatment plants for air dehumidification processes.

3. Energy recovery: They are also used in air exhaust systems for energy recovery purposes.

4. Air coolers: These tubes are utilized in air coolers, which are heat exchangers used for cooling air.

5. Air preheaters: They can be found in air preheaters, which are used to heat the air before it enters a combustion system.

6. Charge air chillers: Extruded serrated finned tubes are used in charge air chillers, which cool the air compressed by turbochargers in internal combustion engines.

7. Condensers: These tubes are utilized in condensers, which are heat exchangers used to condense a substance from its gaseous state to a liquid state.

8. Evaporators: They can be found in evaporators, which are heat exchangers used to convert a liquid into a gaseous state.

9. Fluid coolers: Extruded serrated finned tubes are used in fluid coolers, which cool various fluids in industrial processes.

10. Gas coolers: They can be found in gas coolers, which are used to cool gases in various applications.

11. Oil coolers: These tubes are utilized in oil coolers, which are used to cool oil in engines or hydraulic systems.

12. Radiators: Extruded serrated finned tubes are also used in radiators, which are heat exchangers used for cooling internal combustion engines.

13. Refrigeration: They can be found in refrigeration systems for cooling purposes.

14. Steam to air heat exchangers: These tubes are utilized in steam to air heat exchangers, which transfer heat from steam to air.

Although extruded serrated finned tubes can be more expensive compared to other fin types due to the increased amount of aluminum used (about 40%) and additional labor during manufacturing, this cost can be offset if lower

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!