ASTM A312 TP304H HFW 304 Spiral Finned Tube Heat Transfer Fin Tube Heater

Yuhong Group has over a decade of experience in the finned tube industry, with annual sales surpassing 80,000 tons of stainless steel, duplex, and nickel seamless pipes. Our client base spans across 45 countries. Our stainless steel seamless pipes are extensively utilized in various industries including mining, energy, petrochemical, chemical, food processing, paper production, as well as gas and fluid industries.

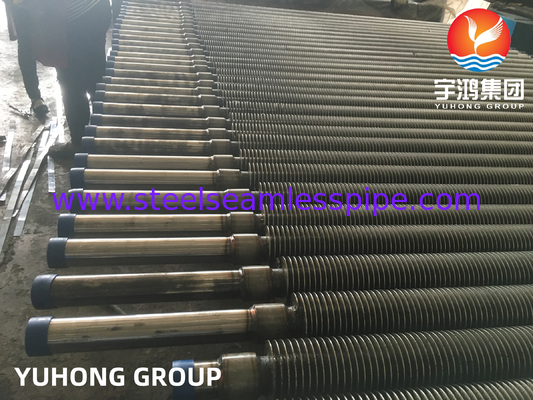

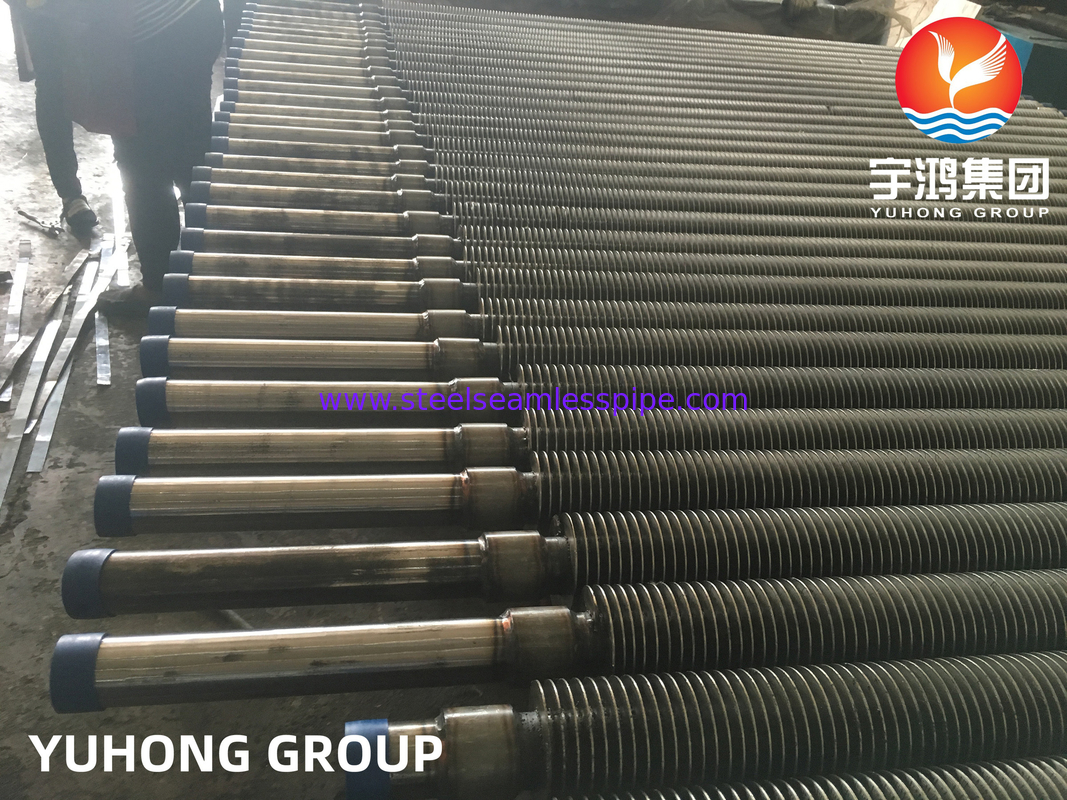

ASTM A213 T12 HFW High Frequency Welded Spiral Helical Solid Finned Tube is a type of heat exchanger tube that is widely used in various industries. It is made by helically winding solid fins onto the outer surface of a seamless tube. The finned tube is then welded using a high-frequency electrical current, ensuring a strong and reliable bond between the fins and the tube.

This finned tube offers excellent mechanical and chemical properties, making it suitable for demanding applications. It has high corrosion resistance, which allows it to withstand harsh environments and corrosive media. Additionally, the high thermal conductivity of the finned tube ensures efficient heat transfer, making it an ideal choice for heat exchangers and boilers.

The ASTM A213 T12 HFW High Frequency Welded Spiral Helical Solid Finned Tube finds applications in various industries, including petrochemical, power generation, and chemical processing. It is commonly used in heat recovery systems, air coolers, and condensers. The finned tube's design and construction make it highly suitable for high-temperature and high-pressure applications.

Some key features of this finned tube include its enhanced heat transfer capability due to the increased surface area provided by the fins. This results in improved efficiency and reduced energy consumption. The helical fins also provide better heat transfer performance in gas flow applications, making it suitable for gas-to-gas heat transfer processes.

When using ASTM A213 T12 HFW High Frequency Welded Spiral Helical Solid Finned Tube, there are a few important considerations. Proper installation and maintenance are vital to ensuring optimal performance and longevity. Regular cleaning is necessary to prevent fouling and maintain efficient heat transfer. It is also important to ensure proper alignment and support during installation to avoid any mechanical stress on the finned tube.

In conclusion, ASTM A213 T12 HFW High Frequency Welded Spiral Helical Solid Finned Tube is a high-quality heat exchanger tube with excellent mechanical and chemical properties. Its unique design and construction make it suitable for various applications, providing enhanced heat transfer efficiency. Proper installation and maintenance are essential to maximize its performance and lifespan.

Chemical Requirements

| Grade |

UNS Designation |

Composition, % |

| |

|

Carbon |

Manganese |

Phosphorus, max |

Sulfur, max |

Silicon |

Chromium |

Nickel |

| T12 |

K11562 |

0.15 MAX |

0.3-0.6 |

0.025MAX |

0.025 MAX |

0.5-1 |

1-1.5 |

0.44-0.65 |

Technical details/base tube details/Fin details

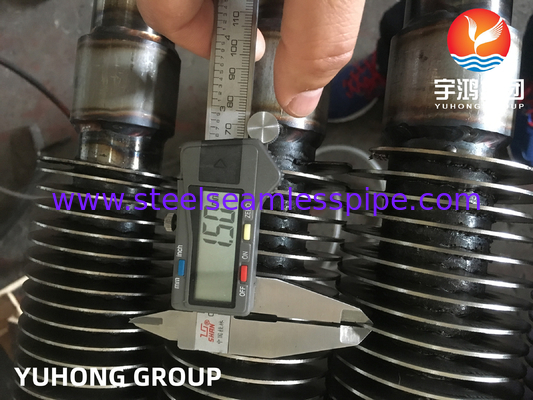

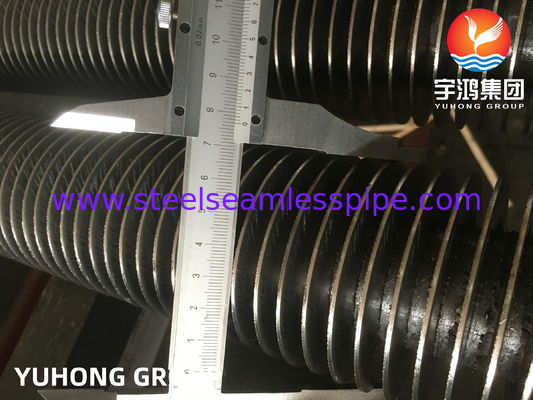

- Pipe Diameter: 20mm (min) to 219mm (max)

- Tube Thickness: 2mm (min) to 16mm (max)

- Tubing Materials: Stainless Steel, Alloy Steel, Carbon Steel, Weathering Steel, Duplex Steel, Super Duplex Steel, Inconel, High Chromium High Nickel, and Incolloy

- Fin Thickness: 0.8mm (min) to 4mm (max)

- Fin Height: 0.25" (6.35mm) (min) to 1.5" (38mm) (max)

- Fin Density: 43 fins per meter (min) to 287 fins per meter (max)

- Fin Materials: Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel, and Incolloy

To request a quick quotation, please provide the following information:

1. Number of pieces

2. Base tube specifications:

- Diameter

- Thickness

- Length

- Material specifications

3. Fin specifications:

- Material

- Type (solid or serrated)

- Height

- Thickness

- Spacing

- Fin length

- Finless section

If welding preparation details are necessary, please provide them as well.

4. Required delivery date.

The fins are cut from metal strips and helically wound around the tube. This configuration offers efficiency, effective fin-to-tube bonding, and the ability to withstand high temperatures on the fin side. The serrated fin configuration provides better heat transfer performance and can handle fin fouling effectively.

Base tube details:

- Pipe diameter range: 15.88mm to 219mm

- Tube thickness range: 1.651mm to 16mm

- Tube materials: Carbon Steel Seamless Tube, Stainless Steel, Carbon Alloy Steel, Weathering Steel, Duplex Stainless Steel, Super Duplex Stainless Steel S32750, Inconel Alloy, High Chromium High Nickel Incoloy Alloy, CK 20 Material, and other materials.

Fin detail:

- Fin Thickness: 0.8mm (min) to 4mm (max)

- Fin Height: 0.25" (6.35mm) (min) to 1.5" (38mm) (max)

Applications for heat exchangers include:

- HVAC & Boilers

- Power plants

- Heat recovery steam generators

- Petrochemical industry

- Marine applications

- Refrigeration applications

- Economizers in oil and gas industry

- Coolers in oil and gas industry

- Plumbing and air conditioning systems

- Condensers and evaporators

- Shell and tube heat exchangers

- Various other heat exchanger applications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!