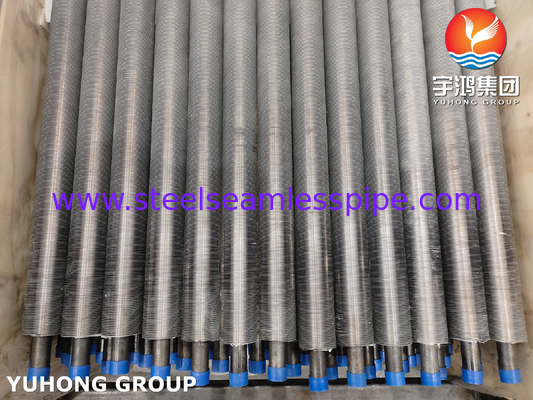

ASTM A179 Carbon Steel Extruded Fin tube Exchanger Tube ECT /HT

Extruded fin tubes are commonly used in heat exchanger applications where efficient heat transfer is essential. The fins increase the surface area of the tube, allowing for improved heat transfer between the fluid flowing inside the tube and the surrounding medium.

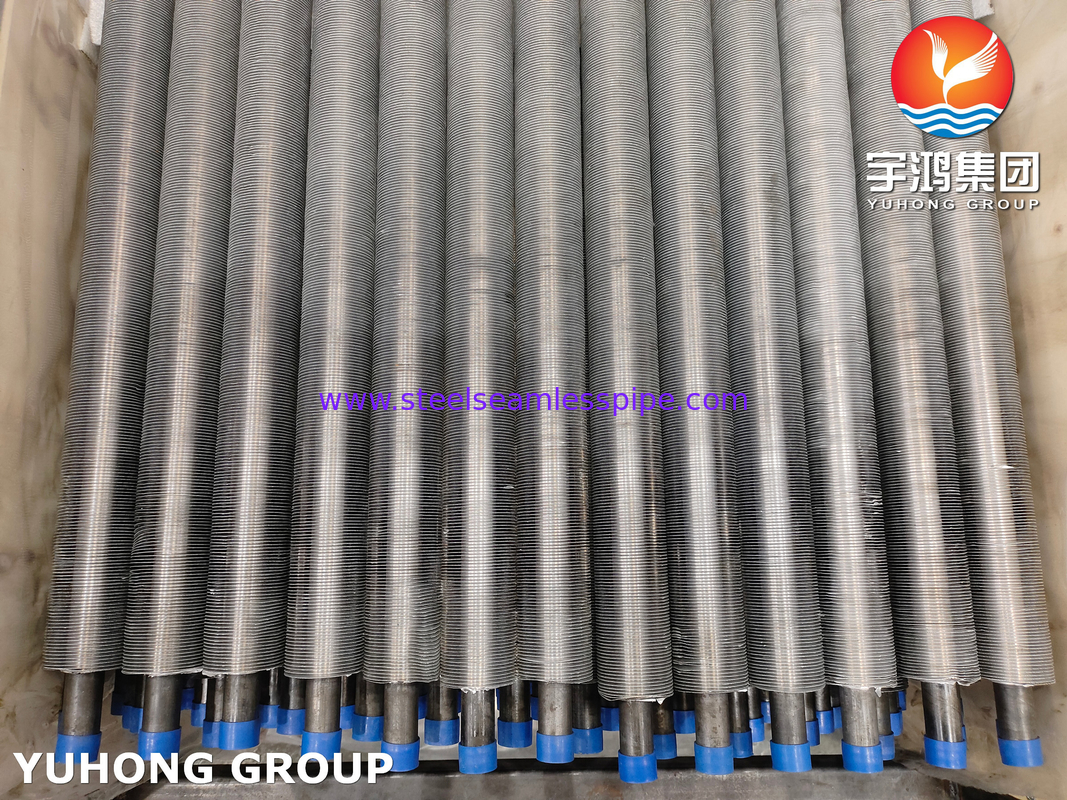

The fins on extruded fin tubes can have various shapes, such as plain, helical (spiral), or serrated, depending on the application and desired heat transfer characteristics. These fins are typically made from aluminum or copper alloys, which offer high thermal conductivity and corrosion resistance.

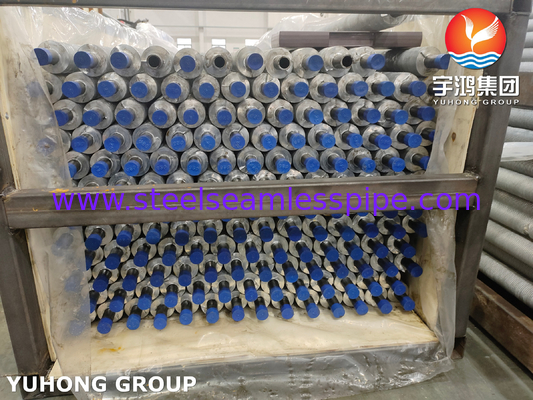

The combination of a base tube and extruded fins results in enhanced heat transfer efficiency, making extruded fin tubes suitable for use in industries such as power generation, chemical processing, HVAC (heating, ventilation, and air conditioning), and refrigeration.

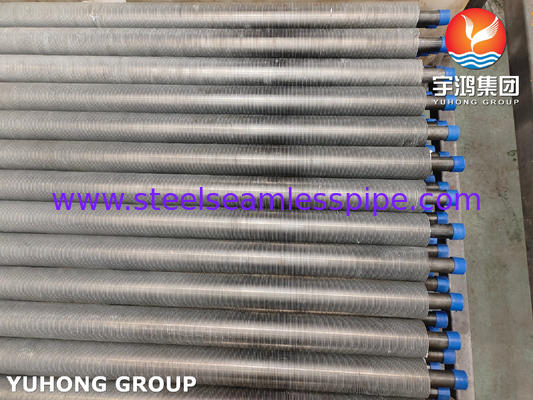

A179 extruded fin tube refers to a type of heat exchanger tube that is made from ASTM A179 seamless carbon steel tubes with extruded aluminum fins attached to the outer surface. These tubes are commonly used in applications where efficient heat transfer is essential, such as in power plants, industrial boilers, heat recovery systems, and air conditioning units.

The extruded fins on the A179 fin tube increase the surface area of the tube, allowing for better heat transfer between the fluid inside the tube and the surrounding medium. The fins are typically helical (spiral) in shape, providing enhanced heat transfer capabilities.

Extruded fin tubes offer several advantages compared to other types of fin tubes.

Here are some of the key advantages:

Enhanced Heat Transfer Efficiency: The extruded fins provide a larger surface area for heat transfer compared to other types of fin tubes. This increased surface area allows for more efficient heat exchange between the fluid inside the tube and the surrounding medium, leading to improved overall performance.

Strong Bonding: The fins on extruded fin tubes are tightly bonded to the base tube, ensuring excellent thermal contact and minimizing the risk of fin failure or detachment. This strong bonding enables efficient heat transfer and enhances the overall durability of the fin tube.

High Thermal Conductivity: Extruded fin tubes often use aluminum or copper alloys for the fins, which offer excellent thermal conductivity.

These materials effectively conduct heat, allowing for quick and efficient transfer from the tube's surface to the fins and surrounding environment.

Corrosion Resistance: Aluminum and copper alloys commonly used in extruded fin tubes exhibit a high level of corrosion resistance. This is especially beneficial in environments where the tube is exposed to corrosive substances or high humidity, ensuring long-term performance and reliability.

Versatile Range of Fin Designs: Extruded fin tubes can be manufactured with various fin designs, including plain fins, helical fins, or serrated fins. This versatility allows for tailoring the fin tube to specific heat transfer requirements, making it suitable for a wide range of applications.

Cost Efficiency: Compared to other fin tube manufacturing methods, such as finned strip wound or welded fin tubes, extruded fin tubes can be produced in larger quantities at a lower cost. This makes them a cost-effective choice for heat exchanger applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!