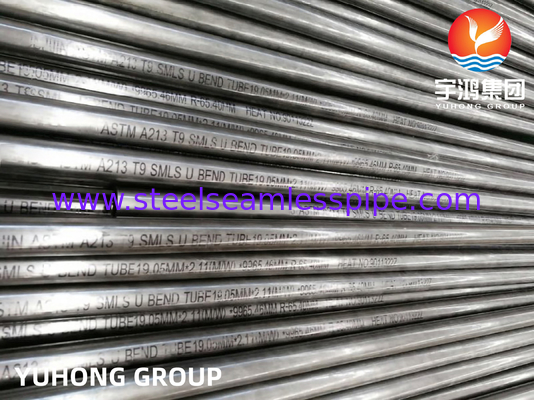

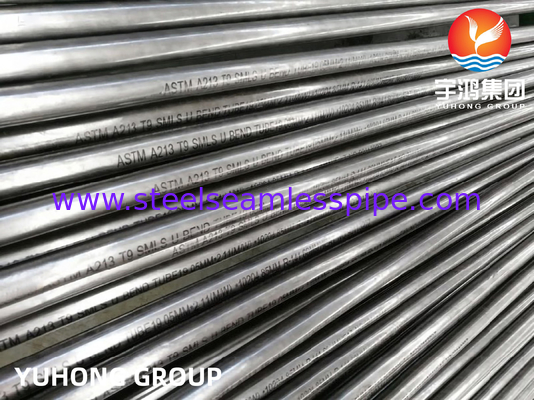

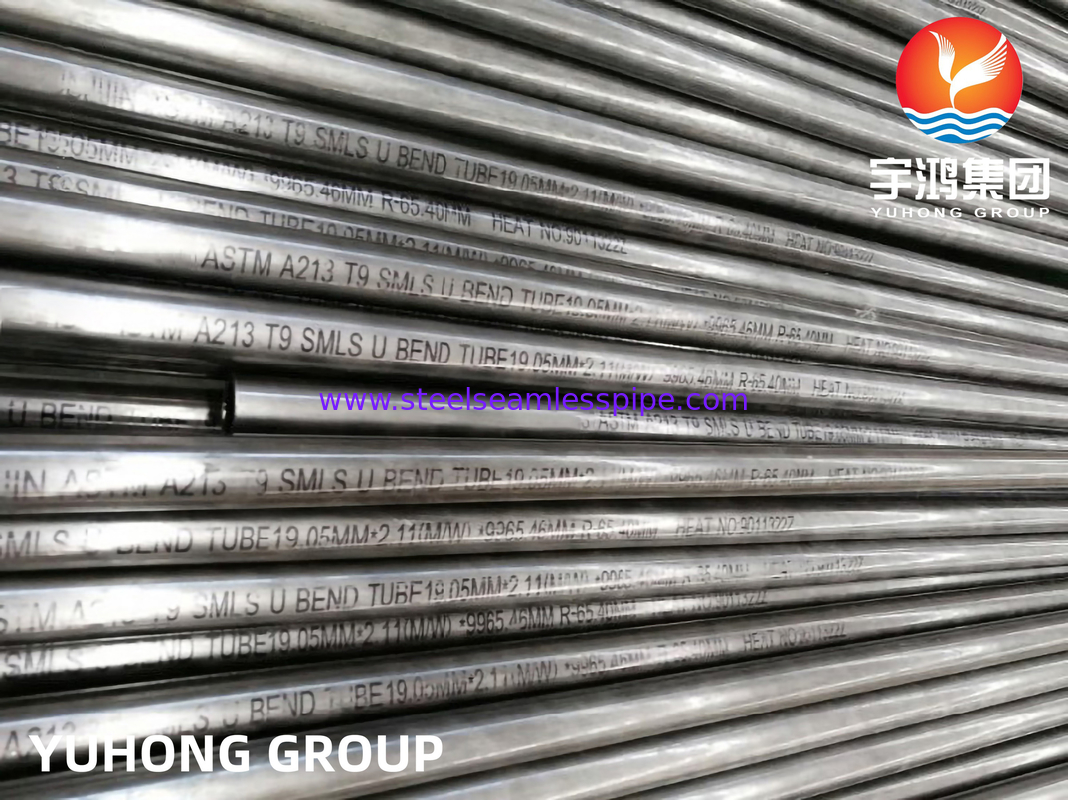

ASME SA213 T9 9Cr1Mo Alloy Steel Seamless U Bend Heat Exchanger Tube

Overview:

The T9 seamless U-bend tube is a specialized tube designed for use in various applications, particularly in industries like aerospace, automotive, and manufacturing. It features a unique U-shaped bend that allows for efficient flow and optimal space management in systems where traditional straight tubes may not fit or perform effectively.

One of the key characteristics of T9 seamless U-bend tubes is their seamless construction, which eliminates welds and joints, thereby enhancing strength and reducing the risk of leaks. This design ensures a more robust structure capable of withstanding high pressure and demanding conditions, making it ideal for high-performance applications.

The manufacturing process generally involves advanced techniques such as precision forming and heat treatment, ensuring that the tubes meet strict quality standards. This attention to detail allows for excellent dimensional accuracy and repeatability, essential for applications where precise measurements are crucial.

Materials used in T9 seamless U-bend tubes often include high-grade alloys, providing benefits such as corrosion resistance and superior mechanical properties. This makes them suitable for harsh environments and extends their service life.

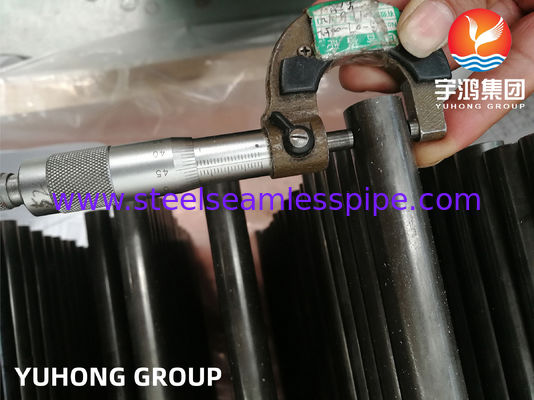

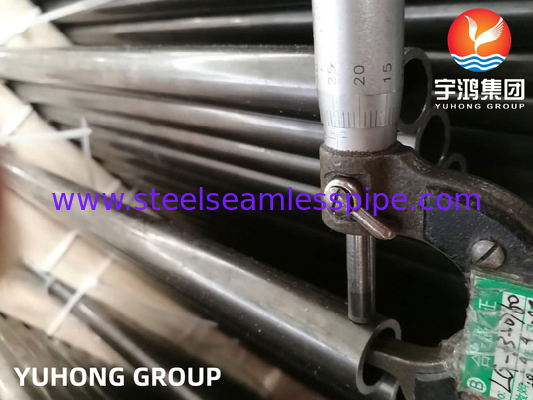

Additionally, T9 U-bend tubes are versatile, available in various diameters and wall thicknesses to meet specific requirements. They can be easily integrated into existing systems due to their adaptable design, making them a go-to choice for engineers and designers.

Specification:

| Standard |

ASTM A213 & Its equivalent ASME, DIN & EN Standard |

| Grades |

T9; 9Cr1Mo |

| Type |

U-ben seamless tube |

| Outer Diameter |

1/4'' to 1'' or custom size |

| Wall Thickness |

BWG25;BWG22;BWG20;BWG18;BWG16;BWG14;BWG12;BWG10 |

| Length |

custom cut lengths |

| Delivery Condition |

Normalize & Temper |

| Ends |

Plain End, Beveled End |

| Other Testing |

Product Analysis, Eddy Current Test, Hydrostatic Test, Ultrasonic Test, Flattening Test, Hardness Test, Tensile Test etc. |

| Dimension |

All Pipe & Tube Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Packing |

Plywood case/Woven bag in bundle |

Chemical Composition:

| Grade |

UNS |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

| T9 |

K90941 |

0.15 max |

0.30-0.60 |

0.025 max |

0.025 max |

0.25-1.00 |

8.0-10.0 |

0.90-1.10 |

Mechanical Properties:

| Grade |

UNS |

Tensile Strength, min, ksi (MPa) |

Yield Strength,

min, ksi (MPa) |

Elongation in 2 in.

or 50mm, min (%) |

Hardness |

| Rockwell |

Brinell/Vickers |

| T9 |

K90941 |

60(415) |

30(205) |

30 |

89HRB |

179HBW/190HV |

Applications:

1. Heat Exchangers: T9 seamless U bend tubes are widely used in heat exchangers for various industries, including power generation, petrochemical, and chemical processing. These tubes facilitate the efficient transfer of heat between hot and cold fluids, making them ideal for applications such as shell-and-tube heat exchangers, condensers, and economizers.

2. Boilers and Superheaters: T9 seamless U bend tubes find application in boilers and superheaters. They are used to generate and superheat steam in power plants and industrial processes that require high-pressure and high-temperature operations. The T9 alloy steel construction provides excellent durability and resistance to creep deformation.

3. Refining and Petrochemical Processes: T9 seamless U bend tubes are employed in the refining and petrochemical industries for applications such as cracking furnaces, reformers, and high-temperature piping systems. These tubes can withstand the corrosive environments and high temperatures associated with these processes, ensuring reliable performance and longevity.

4. Thermal Solar Power Plants: T9 seamless U bend tubes are utilized in thermal solar power plants for the collection and transfer of solar energy. They are incorporated into the receiver tubes of parabolic trough solar collectors, where they absorb solar radiation and transfer it to a working fluid for power generation or other thermal applications.

5. High-Temperature Piping Systems: T9 seamless U bend tubes are suitable for high-temperature piping systems found in various industries, including oil and gas, chemical, and power generation. They can be used for applications such as steam distribution, superheated steam lines, and hot oil circulation systems, where resistance to elevated temperatures and thermal stress is crucial.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!