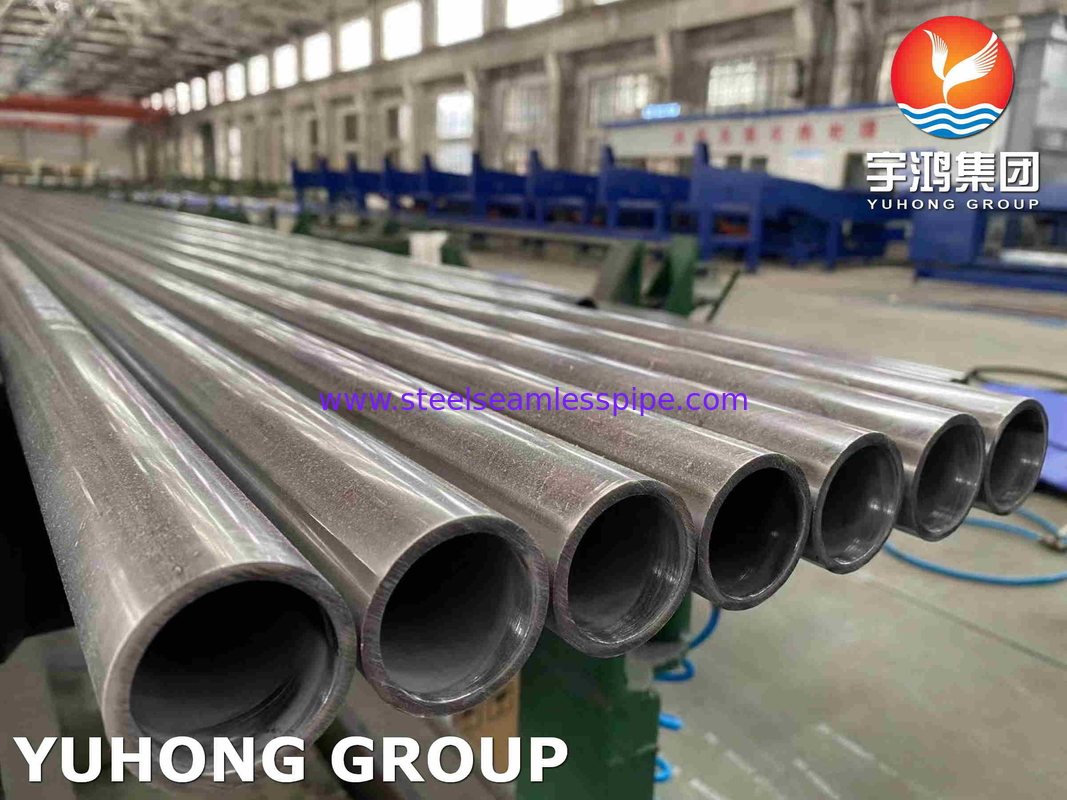

ASME SA179 Cold Drawn Low Carbon Steel Heat Exchanger and Condenser Tube

Overview:

SA 179 seamless tubes are highly regarded for their applications in heat exchangers, condensers, and other critical systems in the oil and gas, power generation, and chemical industries. These tubes are made from carbon steel and are designed to withstand high pressures and temperatures. Key characteristics include their excellent weldability, structural integrity, and resistance to corrosion.

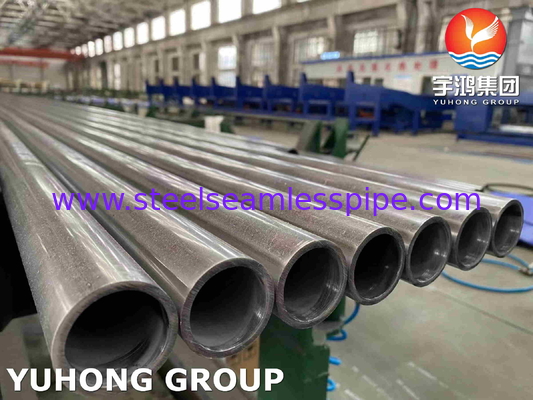

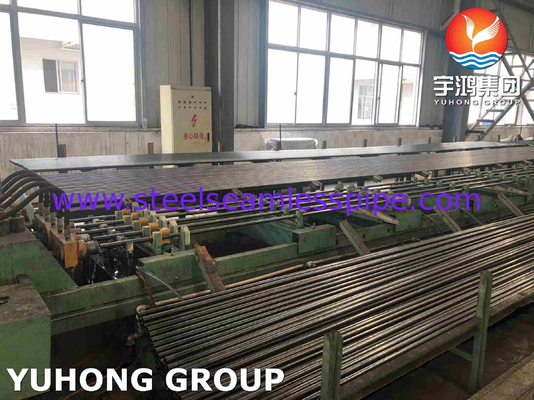

Manufactured under the standards of ASTM (American Society for Testing and Materials), the SA 179 specification outlines requirements for seamless carbon steel tubes. Typically, these tubes are cold drawn, ensuring precise dimensional tolerances and a smooth surface finish, enhancing their performance in heat transfer applications. The typical chemical composition includes carbon, manganese, phosphorus, and sulfur, which contribute to their mechanical properties and overall durability.

The mechanical properties are crucial; the yield strength usually exceeds 30,000 psi, and the tensile strength can be around 45,000 psi, providing superior strength for various applications. These tubes are often used in higher pressure environments, and their ability to endure thermal stress makes them ideal for heat exchangers, which operate under fluctuating temperatures.

Manufacturing processes involve several steps, including billet preparation, heating, piercing, elongation, and final sizing. The quality control measures include rigorous testing for dimensions, mechanical properties, and surface defects. Non-destructive testing methods, such as ultrasonic testing and eddy current testing, are commonly employed to ensure the integrity of the tubes.

Specification:

| Standard |

ASME SA179 & Its equivalent ASTM, DIN & EN Standard |

| Grades |

SA179 |

| Type |

U-bend/Straight seamless tube |

| Outer Diameter |

1/8'' to 3'' or custom size |

| Wall Thickness |

BWG25;BWG22;BWG20;BWG18;BWG16;BWG14;BWG12;BWG10 |

| Length |

Upto 6 meters or custom cut lengths |

| Delivery Condition |

Normalize & Temper |

| Ends |

Plain End, Beveled End |

| Other Testing |

Product Analysis, Eddy Current Test, Hydrostatic Test, Flattening Test, Hardness Test, Tensile Test etc. |

| Dimension |

All Pipe & Tube Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

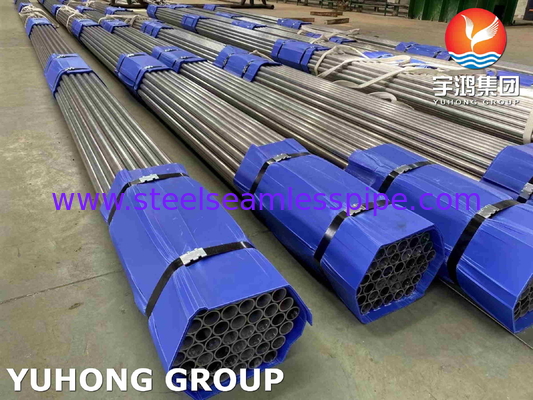

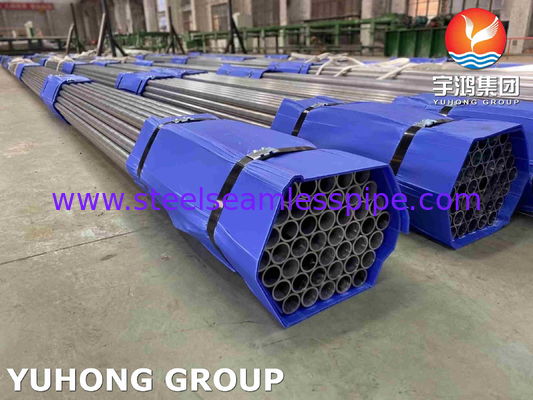

| Packing |

Plywood case/Woven bag in bundle |

Chemical Composition:

| Grade |

C |

Mn |

P |

S |

| SA179 |

0.06-0.18 |

0.27-0.63 |

0.035 max |

0.035 max |

Mechanical Properties:

| Grade |

Tensile Strength

min, ksi (MPa)

|

Yield Strength

min, ksi (MPa)

|

Elongation in 2 in.

or 50mm, min (%)

|

| SA179 |

47(325) |

26(180) |

35 |

Applications:

1. Heat Exchangers: Used extensively in power plants and chemical processing.

2. Boilers: Suitable for high-pressure environments due to their strength and durability.

3. Oil and Gas Industry: Ideal for transporting fluids and gases under high pressure.

4. Chemical Processing: Resistant to corrosion, making them suitable for chemical handling.

5. Cooling Towers: Effective in thermal regulation systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!