| Base Tube Part |

Fin Part |

| Specification |

Material Grade |

Major Sizes |

Material Grade |

Fin Type |

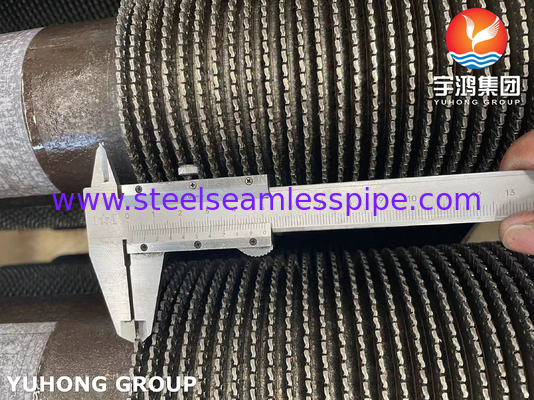

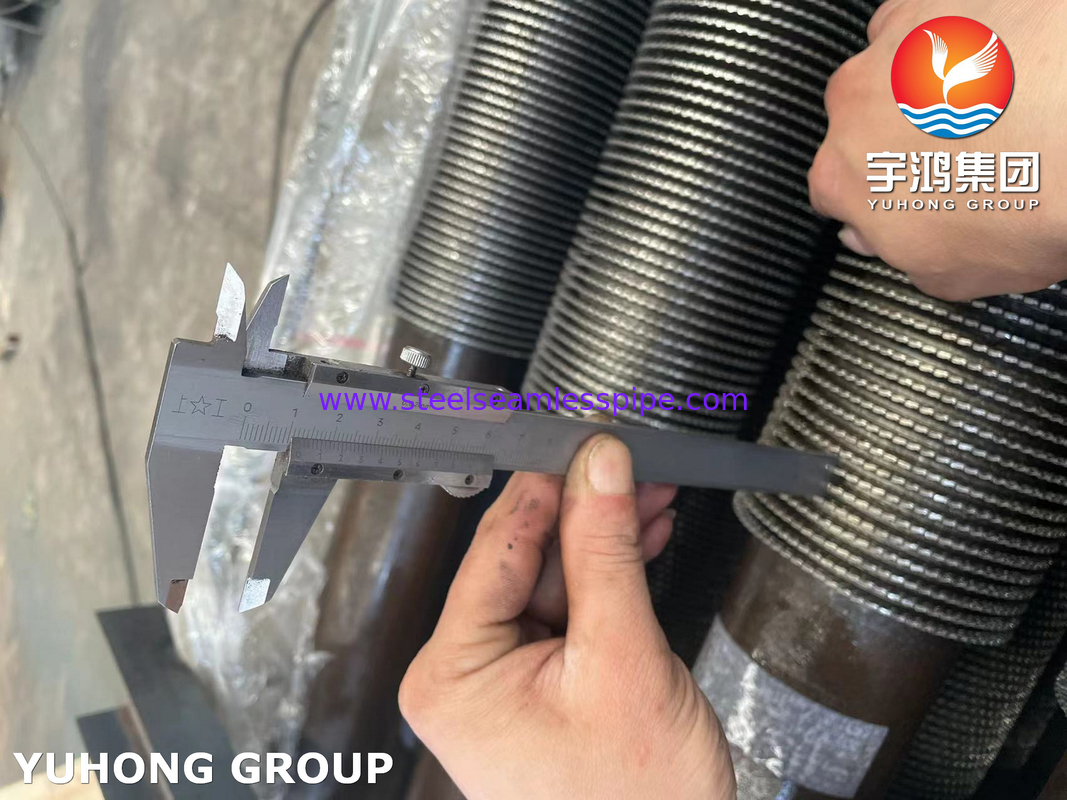

Fin Height |

Fin Thickness |

Fin Qty |

Fin Dia. |

Bare Length |

| ASTM A213 ; ASME SA213; ASTM A249; ASME SA249; ASTM A269; ASME SA269; ASTM A312; ASME SA312; ASTM A376; ASME SA376; ASTM A789; ASME SA789; ASTM A790; ASME SA790 |

TP304, TP304L, TP304H, TP310S, TP310H, TP316L, TP317L, TP321, TP321H, TP347, TP347H , S31803, S32205, S32750, S32760 |

Tube Size: 15.875 X 1.65; 15.875 X 2.11; 15.875 X 2.77; 19.05 X 1.65; 19.05 X 2.11; 19.05 X 2.77; 25.4 X 2.11; 25.4 X 2.77; 25.4 X 3.05; 25.4 X 3.4; 31.75 X 2.11; 31.75 X 2.77; 31.75 X 3.05; 31.75 X 3.4; 38.1 X 2.11; 38.1 X 2.77; 38.1 X 3.05; 38.1 X 3.4; 44.45 X 2.11; 44.45 X 2.77; 44.45 X 3.05; 44.45 X 3.4; 44.45 X 3.81; 44.45 X 4.57; 50.8 X 2.11; 50.8 X 2.77; 50.8 X 3.05; 50.8 X 3.4; 50.8 X 3.81; 50.8 X 4.57; 57.15 X 2.11; 57.15 X 2.77; 57.15 X 3.05; 57.15 X 3.4; 57.15 X 3.81; 57.15 X 4.57; 63.5 X 2.11; 63.5 X 2.77; 63.5 X 3.05; 63.5 X 3.4; 63.5 X 3.81; 63.5 X 4.57; Pipe Size: 2 1/2" SCH40 (73.03 X 5.16); 2 1/2" SCH80 (73.03 X 7.01); 3" SCH40 (88.9 X 5.49); 3" SCH40 (88.9 X 7.62); 3 1/2" SCH40 (101.6 X 5.74); 3 1/2" SCH80 (101.6 X 8.18); 4" SCH40 (114.3 X 6.02); 4" SCH80 (114.3 X 8.56); 5" SCH40 (141.3 X 6.55); 5" SCH80 (141.3 X 9.27); 6" SCH40 (168.3 X 7.11); 6" SCH80 (168.3 X 10.97); 8" SCH40 (219.1 X 8.18); 8" SCH80 (219.1 X 12.7); Length Max.: 25M/PC; other sizes depend on customer request |

Stainless Steel: SS304, SS304L, SS316L, SS317L, SS347, SS310; SS409 (1CR12), SS410(1Cr13); Carbon Steel(CS) , Alloy Steel: ASTM A387 Gr.A, Gr.B, Gr.C; Aluminum ASTM A209 / ASME SA209 AL1060, Gr.6061; ASME SA210/ ASTM A210 AL1060 , AL1100, Gr.6061, Gr.6063, ASTM A221/ ASME SA221 AL 1060 , Gr.6061, Gr.6063 Alloy Steel: P11, P22, P5, P9 |

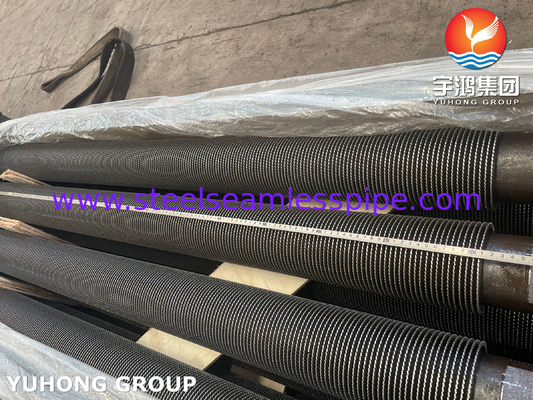

Solid Fin : High Frequency Weldding(HFW), Serrated Fin Tube, Studded Tube /Pin Tube, Square Fin Tube, H Type Fin tube, HH type Fin tube; Embedded : G Type Fin Tube; Wound: L, LL, KL ; Extruded; Thread Fin tube ; Low Fin tube; Corrguated Fin Tube; Bamboo Tube; U bend Fin tube |

1.6mm ~60mm |

0.2mm~3.0mm |

Depend on client request |

12.7mm~25.4mm |

40mm~client request |

| EN10216-5; EN10217-7; DIN 17456; DIN17457; DIN17458 |

1.4301,1.4305, 1.4306, 1.4307, 1.4571,1.4401, 1.4404, 1.4541, 1.4948, 1.4550, 1.4912, 1.4845, 1.4462, 1.4539, 1.4438, 1.4501 |

| ASTM A335; ASME SA335; ASTM A213; ASME SA213 |

T1, T11, T12, T22, T23, T5, T9, T91, T92, P1, P11, P12, P22, P23, P5, P9, P91, P92 |

| ASTM A53; ASTM A106, ASME SA106 |

GR.A, GR.B, GR.C |

| ASTM A178; ASME SA178; ASTM A179, ASME SA179; ASTM A192; ASME SA192; ASTM A209; ASME SA209; ASTM A210; ASME SA210; ASTM A 214; ASME SA214; ASTM A333; ASME SA333 |

Gr.A, Gr.B, Gr.C, A179, A192, T1a, T1b Gr.A1, Gr.1, Gr.3, Gr.6 |

| ASTM B161; ASME SB161; ASTM B163; ASME SB163; ASTM B164; ASME SB164; ASTM B165; ASME SB165; ASTM B167; ASME SB167; ASTM B407; ASME SB407; ASTM B444; ASME SB444; ASTM B622; ASME SB622; ASTM B388; ASME SB388 |

Grade:Hestalloy:C-276, C-4, C-22, C-2000, X, B-2, B-3, G-30, G-35. Monel:400,401, 404, R-405, K500. Inconel:600, 601, 617, 625, 690, 718, 740, X-750. Incoloy:800, 800H, 800HT, 825, 840. Pure Nickel:Ni-200, Ni-201, Ni-270. NS Alloy:Ns 1101, NS1102, NS1103,NS3105. Titanium : Gr.2 , Gr.5, Gr.7, Gr.9 ; |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!