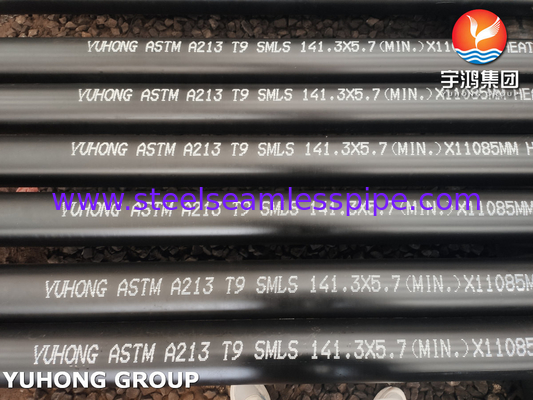

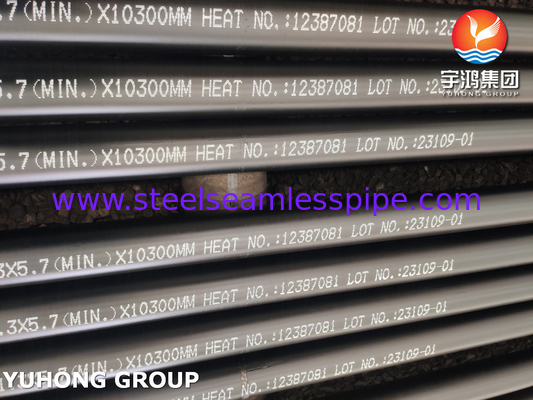

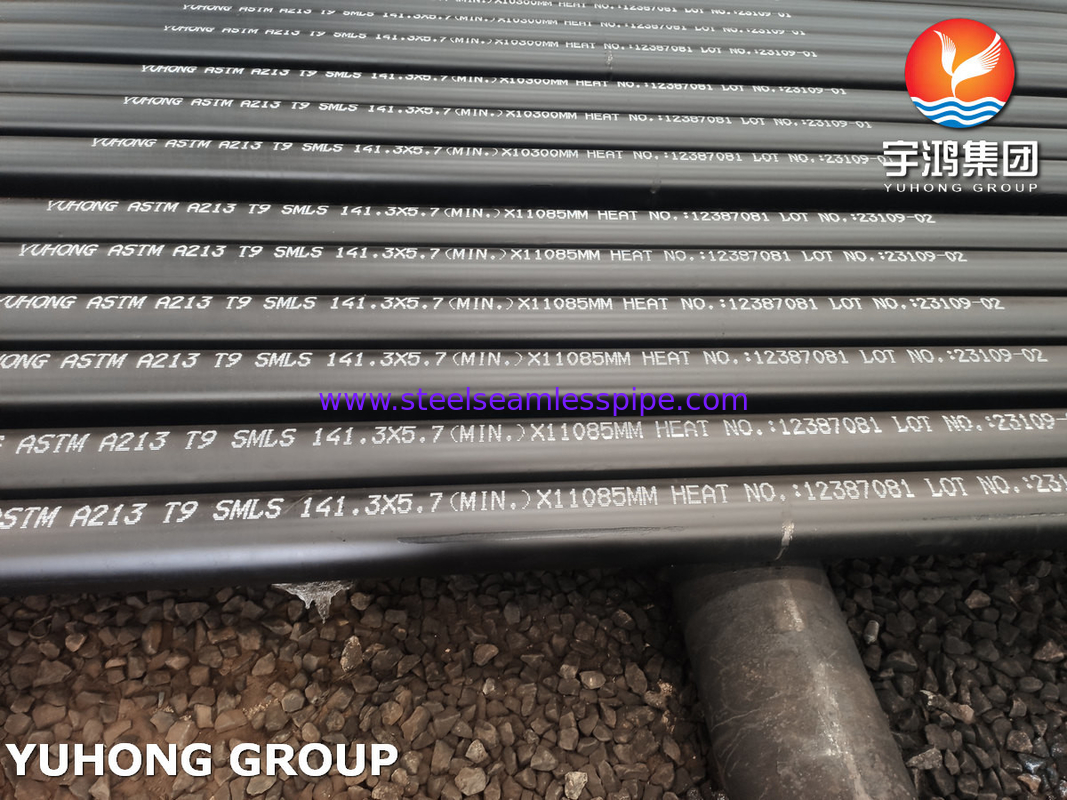

ASTM A213 T9 Alloy Steel Seamless Tube سبائك الصلب أنبوب السلس

The A213 T9 seamless tube is a type of heat-exchanger and boiler tube that is widely used in various industries. It is made from a chromium-molybdenum alloy known as T9, which exhibits excellent corrosion resistance, high-temperature strength, and good weldability.

The A213 T9 seamless tube is known for its durability and reliability, making it a popular choice for critical applications in industries such as power generation, oil and gas, chemical processing, and petrochemicals. It can handle high-pressure steam and corrosive fluids without compromising its performance.

In conclusion, the A213 T9 seamless tube is a high-quality and versatile tube that offers excellent resistance to corrosion, high-temperature strength, and reliability. Its seamless nature and outstanding characteristics make it a preferred choice in various industries requiring efficient heat transfer and dependable performance.

Chemical Composition Of T9

| Cr, % |

C, % |

P, % |

S, % |

Mo, % |

Mn, % |

Si, % |

| 4.00-6.00 |

0.15 max |

0.025 max |

0.025 max |

0.45-0.65 |

0.30-0.60 |

0.50 max |

Mechanical Properties of A213 T9 Alloy Steel Seamless Tubes

| Properties |

Data |

| Tensile strength, min, (MPa) |

415 Mpa |

| Yield strength, min, (MPa) |

205 Mpa |

| Elongation, min, (%), L/T |

30/20 |

Equivalent Material of Alloy Steel T9

| ASTM |

JIS G 3458 |

UNS |

BS |

ISO |

| T9 |

STPA 26 |

S50400 |

3604 P1 629-470 |

2604 II TS38 |

The maintenance of A213 T9 seamless tubes:

1. Regular Inspections:

- Perform visual inspections to check for any signs of damage, corrosion, or leaks.

- Look for any signs of wear or degradation on the surface of the tubes.

- Inspect the connecting joints and fittings for any looseness or leaks.

2. Cleaning:

- Regularly clean the tubes to remove any dirt, debris, or contaminants.

- Use appropriate cleaning agents and tools, such as brushes or compressed air, to clean the tubes thoroughly.

- Ensure that the tubes are completely dry before putting them back into service.

3. Corrosion Prevention:

- Apply appropriate corrosion inhibitors or coatings to protect the tubes from corrosion.

- Regularly inspect the tubes for any signs of corrosion, such as rust or pitting.

- If corrosion is present, take immediate action to repair or replace the affected sections.

4. Pressure Testing:

- Periodically perform pressure tests on the tubes to ensure their integrity and ety.

- Follow the recommended pressure testing procedures and standards for your specific application.

Applications:

1. Power generation: A213 T9 tubes are widely used in power plants for applications such as boiler tubes, superheater tubes, and heat exchanger tubes.

2. Petrochemical industry: These tubes are used in petrochemical refineries for processes such as oil and gas transportation, chemical processing, and heat transfer.

3. Automotive industry: A213 T9 tubes are used in exhaust systems and other high-temperature applications in the automotive industry.

4. Heat exchangers: These tubes are commonly used in heat exchangers where heat is transferred between two fluids. A213 T9 tubes have excellent thermal conductivity and can withstand high temperatures, making them ideal for efficient heat transfer.

5. Aerospace industry: These tubes are used in various aerospace applications, including aircraft engines and components. They are lightweight, durable, and can withstand extreme temperature conditions, making them suitable for aerospace applications.

6. Construction industry: A213 T9 tubes are used in construction projects for structural purposes, such as in the construction of high-rise buildings, stadiums, and bridges.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!