EN10028 1.4541 Stainless Steel Tube Sheet

EN10028 1.4541 is a European standard for stainless steel, specifically for austenitic stainless steel. It is also known as X6CrNiTi18-10 or AISI 321.

A stainless steel tube sheet refers to a flat plate with holes drilled or machined to accommodate tubes. It is commonly used in heat exchangers, boilers, and other pressure vessels to support and hold the tubes in place.

Therefore, EN10028 1.4541 stainless steel tube sheet refers to a tube sheet made from stainless steel grade 1.4541, which is commonly used for its excellent corrosion resistance and high-temperature strength.

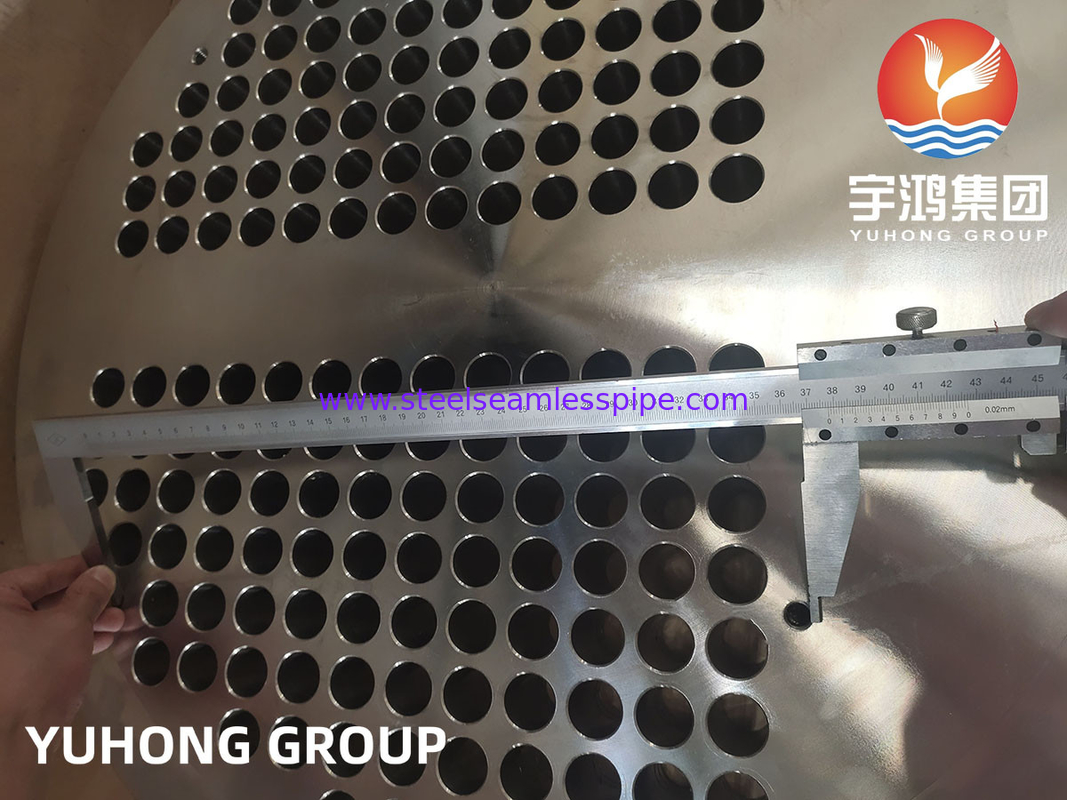

A tube sheet is an essential component of a heat exchanger. It is a circular plate that contains a series of holes to hold the tubes in place. The tubes are inserted through these holes and then expanded or welded to the tube sheet to create a strong and leak-tight connection.

The tube sheet acts as a barrier between the high-pressure and low-pressure sides of the heat exchanger. It ensures that the fluids flowing through the tubes do not mix with each other. The tube sheet also provides support and stability to the tubes, preventing them from sagging or vibrating under operating conditions.

Tube sheets are typically made of materials that can withstand high temperatures and corrosive environments, such as stainless steel, carbon steel, or titanium. The material selection depends on the specific requirements of the heat exchanger, including the type of fluids being processed and the operating conditions.

The design of the tube sheet is crucial for efficient heat transfer and to prevent tube failure. Factors such as the diameter and thickness of the tubes, the pitch (spacing) between the tubes, and the number and arrangement of the holes in the tube sheet are carefully considered during the design process.

In addition to holding the tubes in place, tube sheets also provide a surface for attaching the shell or housing of the heat exchanger. The shell is typically bolted or welded to the tube sheet to create a sealed enclosure for the tubes.

The tube sheet plays a vital role in the performance and reliability of a heat exchanger. It ensures proper fluid separation, supports the tubes, and provides a secure connection between the tubes and the shell.

1.4541 Chemical Composition

| |

Chemical Composition, % |

| Steel Grade |

C, ≤ |

Si, ≤ |

Mn, ≤ |

P, ≤ |

S, ≤ |

Cr |

Ni |

Ti |

| X6CrNiTi18-10 (1.4541) |

0,08 |

1,00 |

2,00 |

0,045 |

0,015 |

17,0-19,0 |

9,0-12,0 |

5xC to 0,70 |

1.4541 Equivalent Grades

| EN X6CrNiTi18-10 (1.4541) material equivalent grade |

| European Union |

US |

ISO |

China |

Japan |

| Steel Name (Material Number) |

Grade (UNS) |

Grade (ISO number ) |

Grade (UNS) |

Grade |

| X6CrNiTi18-10 (1.4541) |

321 (UNS S32100) |

X6CrNiTi18-10 (4541-321-00-I ) |

0Cr18Ni10Ti; |

SUS321 |

| 06Cr18Ni11Ti (new designation) (S32168) |

The production process of a tubesheet involves several steps, including material selection, design, machining, and quality control.

1. Material selection: The tubesheet is typically made from a high-quality metal or alloy, such as carbon steel, stainless steel, or titanium. The material selection depends on the specific application, including factors such as temperature, pressure, and corrosion resistance.

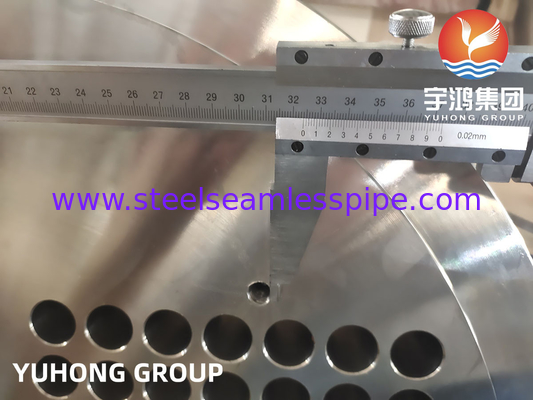

2. Design: The tubesheet design is based on the requirements of the heat exchanger or pressure vessel it will be used in. The design includes the number and arrangement of tube holes, thickness, and overall dimensions.

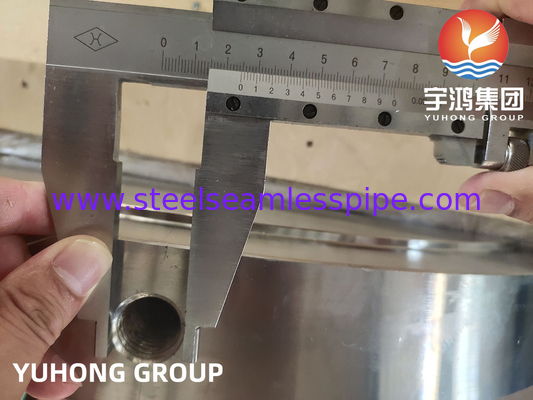

3. Machining: The tubesheet is machined using various processes, including drilling, milling, and turning. The first step is to drill the tube holes in the tubesheet. This is done using a specialized drilling machine or CNC (Computer Numerical Control) equipment. The holes must be accurately positioned and aligned to ensure proper tube insertion.

4. Finishing: After drilling, the tubesheet is typically machined to achieve the desired thickness and surface finish. This may involve milling or turning operations to remove excess material and create a smooth, flat surface.

5. Heat treatment: Depending on the material and application, the tubesheet may undergo a heat treatment process to improve its mechanical properties, such as hardness and strength. This step is crucial for ensuring the tubesheet can withstand the required operating conditions.

6. Quality control: Throughout the production process, quality control measures are implemented to ensure the tubesheet meets the required specifications. This may involve dimensional inspections, non-destructive testing (such as ultrasonic or radiographic testing), and visual inspections.

7. Assembly: Once the tubesheet is machined and inspected, it can be assembled into the heat exchanger or pressure vessel. This involves inserting the tubes into the tube holes and securing them in place using methods such as welding or expansion.

8. Final inspection: Before the heat exchanger or pressure vessel is put into service, a final inspection is conducted to verify that the tubesheet and the entire assembly meet all the required specifications and standards.

It's important to note that the production process of a tubesheet can vary depending on the specific requirements of the application and the manufacturer's capabilities.

The tube sheet serves several important functions in these applications:

1. Tube Support

2. Tube Sealing

3. Heat Transfer

4. Pressure Containment

5. Tube Alignment

6. Tube Cleaning

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!