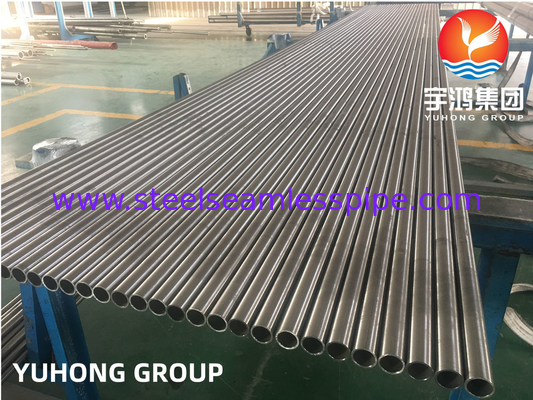

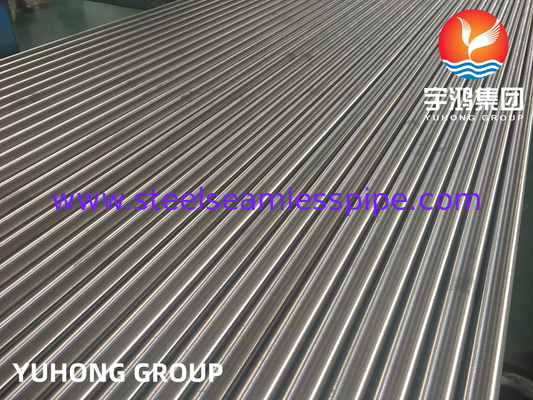

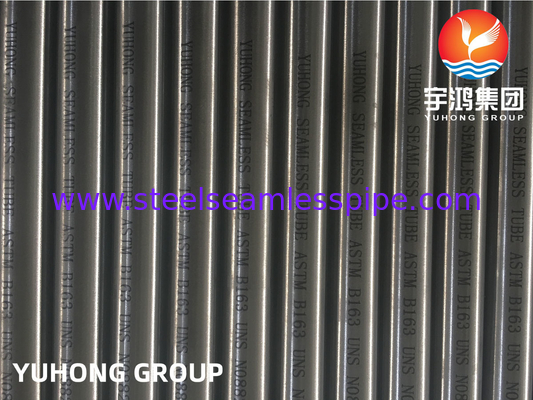

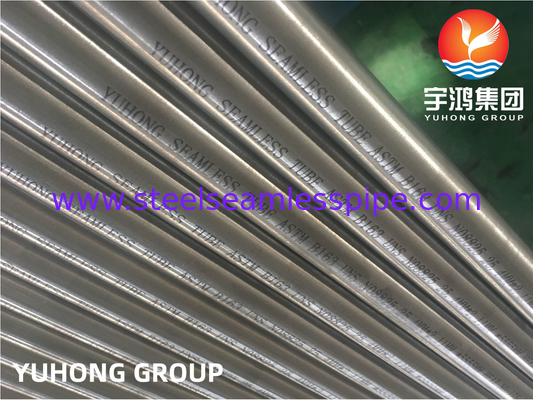

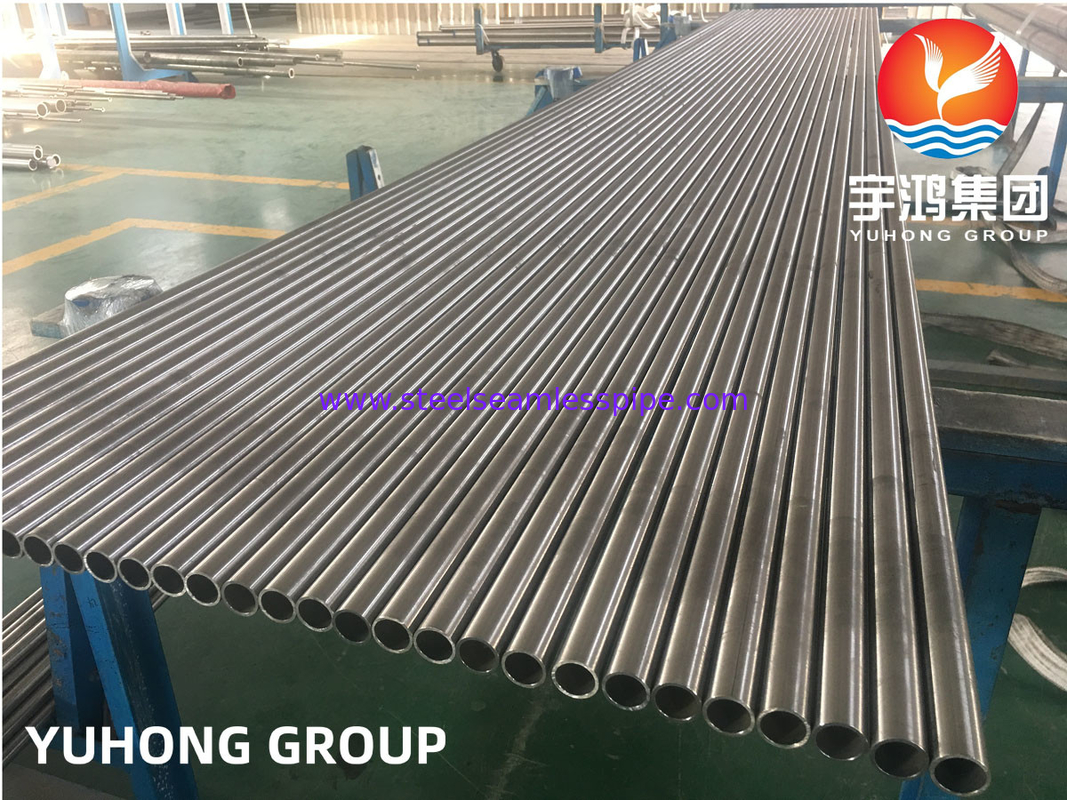

ASME SB163 N08825 Nickel Alloy Seamless Tube For Condensers And Heat Exchangers

YUHONG GROUP deal with stainless steel seamless pipe and tube already more than 33 years, every year sell more than 80000 tons of stainless steel seamless pipe and tube. Our client already cover more than 65 countries. Our stainless steel seamless pipe and tube was width used in Mining, Energy, Petrochemical, Chemical Industry, Food plant, Paper plant, Gas and Fluid Industry etc.

ASME SB163 N08825 is a specification that covers seamless nickel alloy tubes made from grade N08825 material. N08825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. It is commonly known as Incoloy 825.

This specification is applicable for tubes in sizes ranging from 1/8" to 5" in outside diameter and 0.015" to 0.500" in wall thickness. The tubes are intended for general corrosion resistance and high-temperature applications.

The ASME SB163 N08825 nickel alloy seamless tubes are typically used in industries such as chemical processing, oil and gas, power generation, and marine applications. They offer excellent resistance to various corrosive environments, including sulfuric acid, phosphoric acid, and seawater.

The tubes are manufactured using various processes, including cold working, hot working, and annealing. They are tested for mechanical properties, such as tensile strength and yield strength, as well as other quality requirements like flattening, flaring, and hydrostatic testing.

ASME SB163 N08825 nickel alloy seamless tubes provide excellent corrosion resistance, high strength, and good weldability, making them suitable for a wide range of demanding applications.

Chemical Composition:

| Grade |

Ni |

Cu |

Mo |

Fe |

Mn |

C |

Si |

S |

Cr |

Al |

Ti |

| UNS N08825 |

38.0-46.0 |

1.5-3.0 |

2.5-3.5 |

22.0 min. |

1.0 max. |

0.05 max. |

0.50 max. |

0.03 max. |

19.5-23.5 |

0.2 max. |

0.6-1.2 |

Mechanical Properties:

| Grade |

Tensile Strength, min, ksi (MPa) |

Yield Strength,

min, ksi (MPa)

|

Elongation in 2 in.

or 50mm, min (%)

|

| UNS N08825 |

85(586) |

35(241) |

30 |

ASTM B163 Material Chemical Composition Limits

| |

Inconel 600 |

Inconel 601 |

Nickel 200 |

Nickel 201 |

Monel 400 |

Incoloy 800 |

Incoloy 800H |

Incoloy 825 |

| Nickel |

72.0 min |

58.0 to 63.0 |

99.0 min |

99.0 min |

63.0 min |

30.0 to 35.0 |

30.0 to 35.0 |

38.0 to 46.0 |

| Copper |

0.5 max |

1.0 max |

0.25 max |

0.25 max |

0.25 max |

0.75 max |

0.75 max |

1.5 to 3.0 |

| Molybdenum |

- |

- |

- |

- |

- |

- |

- |

2.5 to 3.5 |

| Iron |

6.0 to 10.0 |

Remaining |

0.40 max |

0.40 max |

2.5 max |

39.5 min |

39.5 min |

22.0 min |

| Manganese (max) |

1 |

1 |

0.35 |

0.35 |

2 |

1.5 |

1.5 |

1 |

| Carbon |

0.15 max |

0.1 |

0.15 max |

0.02 max |

0.3 max |

0.10 max |

0.05 to 0.10 |

0.05 max |

| Silicon |

0.5 |

0.5 |

0.35 |

0.35 |

0.5 |

1 |

1 |

0.5 |

| Sulfur (max) |

0.015 |

0.015 |

0.01 |

0.01 |

0.024 |

0.015 |

0.015 |

0.03 |

| Chromium |

14.0 to 17.0 |

21.0 to 25.0 |

- |

- |

- |

19.0 to 23.0 |

19.0 to 23.0 |

19.5 to 23.5 |

| Aluminum |

- |

1.0 to 1.7 |

- |

- |

- |

0.15 to 0.60 |

0.15 to 0.60 |

0.2 max |

| Titanium |

- |

- |

- |

- |

- |

0.15 to 0.60 |

0.15 to 0.60 |

0.6 to 1.2 |

SB163 Seamless Tubes Mechanical Properties

| Grade(Composition) |

UNS NO |

Condition |

Yield Strength(0.2% Offset),min, ksi (MPa) |

Tensile Strength min, ksi (MPa) |

Elongation in 2 inches or 50mm(or 4D) min |

Rockwell Hardness(Or equivalent) for annealed ends |

| Nickel 200(Nickel Alloy) |

UNS N02200 |

|

|

|

|

|

| Nickel 201 |

UNS N02201 |

|

|

|

|

|

| Monel 400 |

UNS N04400 |

|

|

|

|

|

| Inconel 600 |

UNS N06600 |

Annealed |

35(241) |

80(552) |

30 |

- |

| Inconel 601 |

UNS N06601 |

Annealed |

30(207) |

80(552) |

30 |

- |

| Incoloy 800 |

UNS N08800 |

|

|

|

|

|

| Incoloy 800H |

UNS N08810 |

Annealed |

25(172) |

65(448) |

30 |

- |

| Incoloy 800HT |

UNS N08811 |

Annealed |

25(172) |

65(448) |

30 |

- |

| Incoloy 800HT |

UNS N08811 |

Annealed |

25(172) |

65(448) |

30 |

- |

| Incoloy 825 |

UNS N08825 |

Annealed |

35(241) |

85(586) |

30 |

- |

Applications

1. Oil and Gas Industry

2. Chemical Processing

3. Power Generation

4. Desalination Plants

5. Aerospace Industry

6. Marine Industry

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!