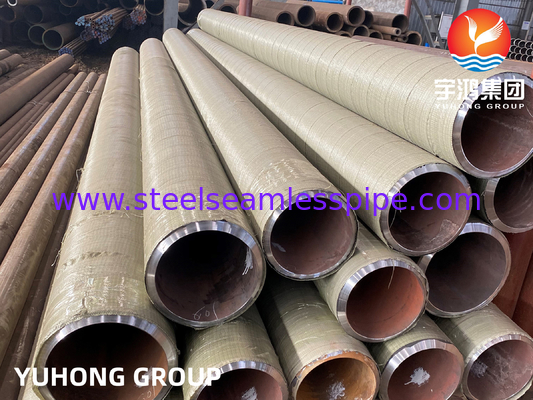

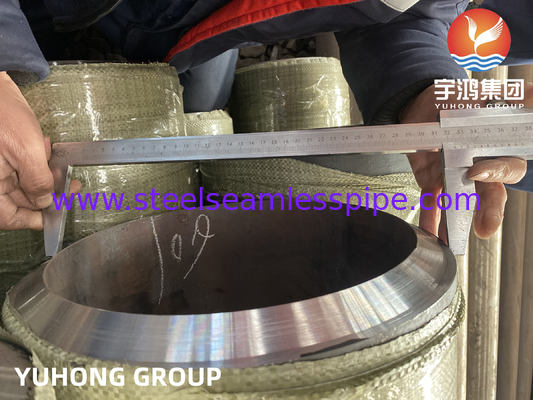

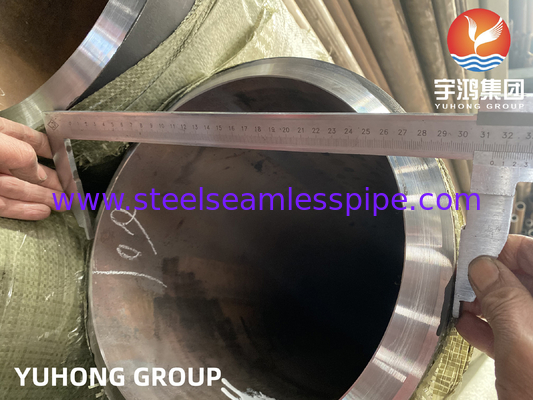

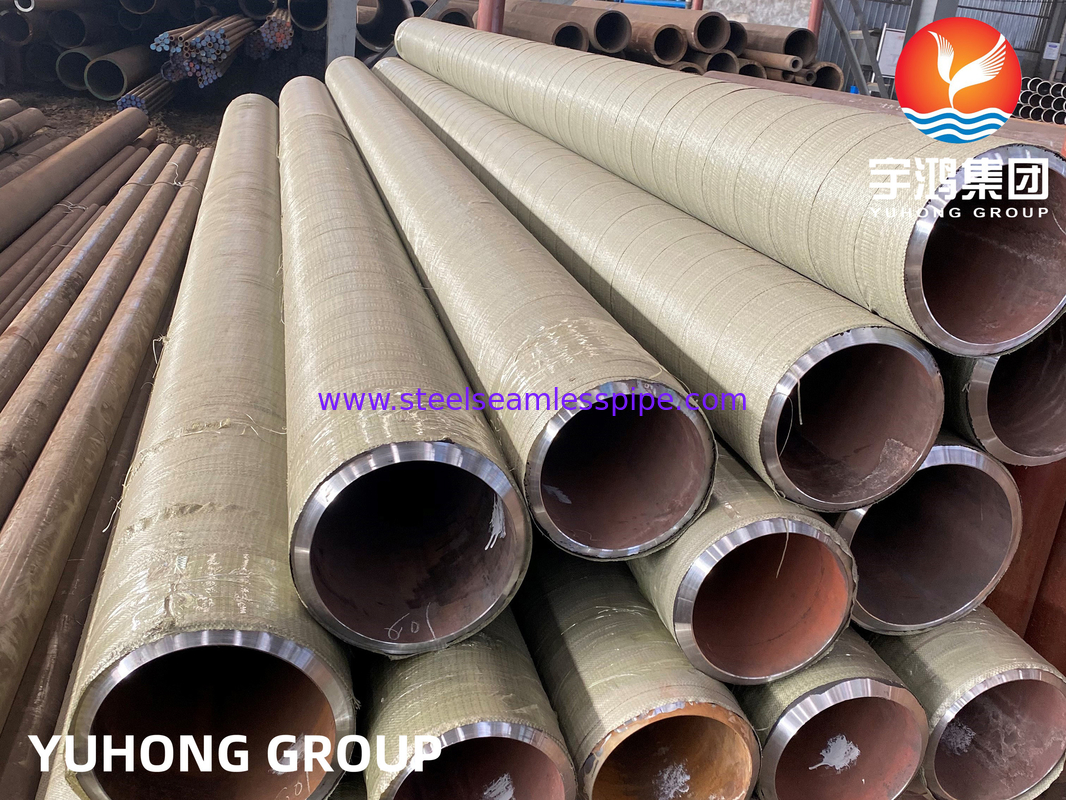

ASTM A335 P22 Alloy Steel Seamless Tubes Hot Rolled for Boiler

YUHONG is one of the biggest manufactures of stainless steel & duplex steel & alloy steel tubes and pipes in China.

1.Manufacture method: cold rolled, cold drawn, hot rolled.

2,material:P22

2.Standard:ASTM A335 p22

3.Size range: 12.7mm*1.2mm - 325mm*50mm

4.Delivery condition: normalized, normalized+tempered,Quenched+tempered

5.Payment terms: T/T 30%payment in advance, 70% T/T before shipment or by L/C

6.Packing: Export sea worthy package

7.END:<2" (60.3mm) Plain end;>2"(60.3mm) Bevelled end; Square cut;Plastic caps at both ends

8.Application:Structural use ,roofing, commercial use, household appliance, industry, family etc

9.Quality control:

a)Mill Test Certificate is supplied with shipment.

b)Third party inspection is highly welcomed.

P22 Pipe Chemical Requirements

| Propriétés chimiques |

|

| Carbone |

Silicium |

Manganèse |

Phosphoreux |

Soufre |

Molybdène |

Nickel |

Chrome |

Cuivre |

Autres |

| 0.05-0.15 |

0,50 max |

0.30-0.60 |

0.025 |

0.025 |

0.87-1.13 |

– |

1.90-2.60 |

– |

– |

P22 Pipe Mechanical Properties

| Tensile Strength, MPa |

Yield Strength, MPa |

Elongation, % |

| 415 min |

205 min |

30 min |

ASTM A335 Gr P22 Equivalent Material

| Désignation équivalente |

| VACARME |

FR |

BS |

NFA |

ASTM |

COMME MOI |

| DIN 17175 Grade 10CrMo9-10 |

EN 10CrMo9-10 Grade 10253 - 2 |

NFA A 49-215 Grade TU 10 CD 9-10 |

ASTM A335 Grade P22 |

ASME SA 335 Grade P22 |

UNI G3458 |

Heat Treatment Requirements

| |

P5, P9, P11, and P22 |

|

|

| Grade |

Heat Treatment Type |

Normalizing Temperature Range F [C] |

Subcritical Annealing or Tempering Temperature Range F [C] |

| P5 (b,c) |

Full or Isothermal Anneal |

|

|

| |

Normalize and Temper |

|

1250 [675] |

| |

Subcritical Anneal (P5c only) |

|

1325 - 1375 [715 - 745] |

| P9 |

Full or Isothermal Anneal |

|

|

| |

Normalize and Temper |

|

1250 [675] |

| P11 |

Full or Isothermal Anneal |

|

|

| |

Normalize and Temper |

|

1200 [650] |

| P22 |

Full or Isothermal Anneal |

|

|

| |

Normalize and Temper |

|

1250 [675] |

| P91 |

Normalize and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

| |

Quench and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

Tensile Requirements

| Seamless |

ASTM A335 P5 |

ASTM A335 P9 |

ASTM A335 P11 |

ASTM A335 P22 |

ASTM A335 P91 |

| Tensile Strength, min., psi |

|

|

|

|

|

| ksi |

60 |

60 |

60 |

60 |

85 |

| MPa |

415 |

415 |

415 |

415 |

585 |

| Yield Strength, min., psi |

|

|

|

|

|

| ksi |

30 |

30 |

30 |

30 |

60 |

| MPa |

205 |

205 |

205 |

205 |

415 |

ASTM A335 Grade P22 pipes are commonly used in applications such as power generation, petrochemical plants, refineries, and other high-temperature and high-pressure environments where resistance to corrosion, high temperature, and stress are crucial.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!