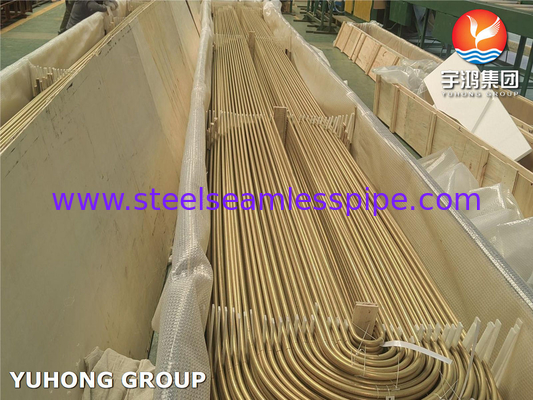

ASTM B111 C68700 Seamless Alumium Copper Alloy Tube For Condenser

Aluminum Brass Tube - C68700 - Resists the action of high velocity salt and black water, commonly used in condenser tubes. The main feature of the C68700 is its high resistance to shock attacks. Tubes of this alloy are recommended for cooling marine and terrestrial power stations with high water velocities.

Our ASTM B111 C68700 tubes are widely used in surface condensers, heat exchangers and evaporators. They have high strength at high temperatures, excellent corrosion resistance and good creep resistance. C68700 has particularly good corrosion resistance in seawater

C68700 has particularly good corrosion resistance in seawater. C44300 and C68700 have good corrosion resistance. C68700 was annealed in the O61 temper. The lowest tensile strength is 345Mpa, and the lowest yield strength is 125Mpa.

C68700 has a density of 8.33g/cm3, 0.301lb/in.3

Typical Application of C68700 Aluminum Brass "As"

Industrial: condenser tubes, evaporator tubes, ferrules, still tubes, heat exchanger tubes

C68700 aluminum brass tubes are widely used in "seawater desalination plants"

Extended test

When expanded in accordance with Test Method B 153, pipe samples selected for testing shall withstand the expansion indicated in the standard. The expanded tube shall show no visible cracks or ruptures.

Hard-drawn tubes that have not been final annealed are exempt from this test. This test is required when the pipe is specified to be end annealed and should be performed on the annealed end of the sample pipe.

Tubing used for ferrule stock is not tested for expansion.

Flattening test

Test Method—Each test specimen shall be flattened in the press at three (3) locations along its length, with each new location being rotated approximately one-third of a turn on its axis from the last flattened area. Each flat area should be at least 2 inches in length. The flattened specimen shall allow free passage of a micrometer caliper set at three (3) times the wall thickness over the flattened area. The flat areas of the test specimens should be inspected for surface defects.

During inspection, the flat areas of the test specimen shall be free from defects, but defects that do not affect the properties of the intended application are acceptable.

Tubes for ferrule stock do not need to be flattened tested.

Residual Stress Test

Only copper alloys UNS numbers C23000, C28000, C44300, C44400, C44500, C60800, C61300, C61400 and C68700 require residual stress testing.

Unless otherwise specified, the manufacturer may choose to test the product by the Mercury Nitrate Test (Test Method B 154) or the Ammonia Vapor Test (Test Method B 858) as specified below.

Non-destructive testing

Eddy Current Test - Each tube shall be passed through an eddy current test apparatus adjusted to provide information on the suitability of the tube for the intended application. Testing shall follow the procedures in Practice E 243.

Hydrostatictest

Each tube shall withstand an internal hydrostatic pressure sufficient to subject the material to a fiber stress of 7000 psi [48 MPa] in the absence of evidence of leakage, as determined by the following equation for a thin hollow cylinder in tension The formula is determined. Unless otherwise specified, pipe need not be tested to hydrostatic pressures in excess of 1000 psi [7.0 MPa].

Advantage:

-

Excellent Corrosion Resistance:

- C68700 tubes exhibit excellent resistance to corrosion, especially in marine and industrial environments. They resist biofouling and the effects of seawater, making them ideal for heat exchangers, condensers, and desalination plants.

-

High Strength and Durability:

- These tubes have high mechanical strength and good durability, making them suitable for applications where both strength and resistance to wear and tear are critical.

-

Good Thermal Conductivity:

- Aluminum brass tubes have good thermal conductivity, which is essential for efficient heat transfer in applications such as heat exchangers and condensers. This property ensures optimal performance in cooling and heating systems.

-

Resistance to Dezincification:

- C68700 tubes are resistant to dezincification, a common form of corrosion in brass alloys where zinc is selectively leached out, leading to weakening of the material. This resistance ensures longer service life in corrosive environments.

-

Formability and Workability:

- These tubes are relatively easy to form and fabricate, allowing for various shapes and sizes to be produced to meet specific application requirements. They can be easily bent, shaped, and joined by soldering or brazing.

-

Cost-Effective:

- Aluminum brass tubes offer a good balance of cost and performance. They are generally more affordable than other high-performance alloys while still providing excellent corrosion resistance and mechanical properties.

-

Compatibility with Various Environments:

- The tubes perform well in different environmental conditions, including high-pressure and high-temperature settings. This versatility makes them suitable for a wide range of industrial applications.

-

Long Service Life:

- Due to their robust corrosion resistance and mechanical properties, C68700 tubes have a long service life, reducing the need for frequent replacements and maintenance.

-

Biostatic Effect:

- The copper content in aluminum brass has a biostatic effect, meaning it inhibits the growth of bacteria and algae. This property is particularly beneficial in applications involving water, as it helps maintain cleaner systems.

| UNS No. |

C68700 – BSI No. CZ110 – ISO Name CuZn22AI2 |

| Chemical Comp. (%) |

Cu 76 ~ 79 / Al 1.8 ~ 2.5 / Pb 0.07 / Fe 0.06 max / Zn rem / As 0.02 ~ 0.06 |

| ASTM Spec. |

B 111, B 395 |

| ASME Spec. |

SB 111, SB 395 |

| Applications |

Condenser, Evaporator and Heat Exchanger tubes; Distiller tubing. |

| Temper |

O61 Annealed |

| Properties * |

Metric |

British |

| Density |

8.33 g/cc |

0.301 lb/in³ |

| Tensile Strength, min. |

345 MPa |

50 ksi |

| Yield Strength, min. |

125 MPa |

18 ksi |

| CTE, linear |

18.5 10-6/°C @ 20.0 – 300 °C |

10.3 10-6/°F @ 70.0 – 570 °F |

| Specific Heat Capacity |

0.09 cal/g-°C @ 20ºC |

0.09 BTU/lb-°F @ 70ºF |

| Thermal Conductivity |

100.4 W/m-K @ 20.0 °C |

58 BTU/ft2/ft/h/°F @ 70.0 °F |

| Melting Point |

932 ~ 971 °C |

1710 ~ 1780 °F |

ASTM B111 C68700 Tube Chemical Composition

| Element |

Weight % |

| Copper |

76.0-79.0 |

| Zinc |

Reminder |

| Aluminium |

1.8-2.5 |

| Arsenic |

0.02-0.06 |

| Lead |

0.07 |

| Iron |

0.06 max |

|

C68700 Brass Tubes Standard Specification:

| COUNTRY |

STANDARD |

NAME |

| ASTM |

ASTM B111 |

Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock |

| GB/T |

GB/T8890 |

Seamless Copper Alloy Heat Exchanger Tubes |

| BS |

BS 2871 CZ110 |

Copper and Copper Alloys Tubes |

| JIS |

JIS H3300 |

Copper and Copper Alloy-Seamless Pipes and Tubes |

| DIN |

DIN1785 |

Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers |

Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and MacroTest

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!