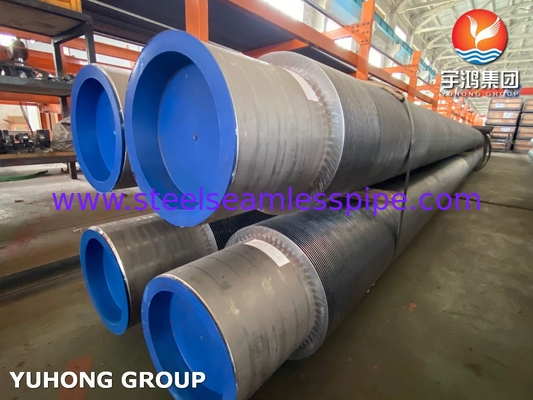

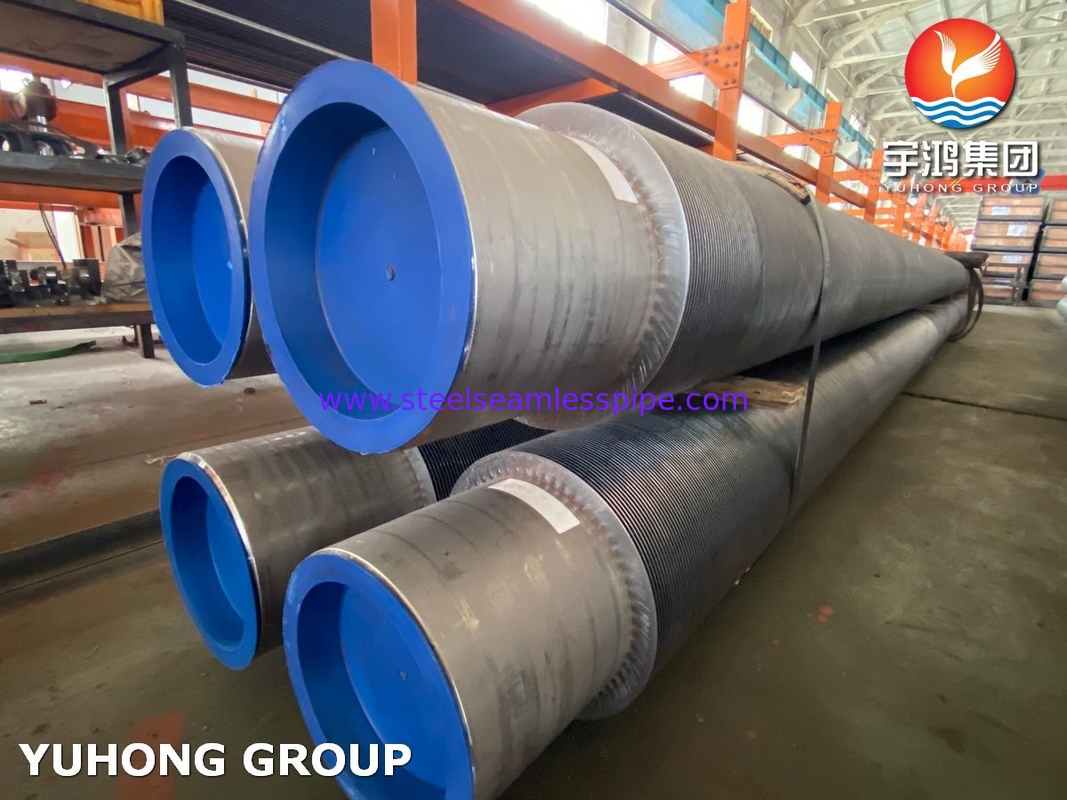

Stainless Steel Finned Pipe, ASTM A312 TP347H SS Fin for Steam Furnace

A Stainless Steel HFW (High-Frequency Welded) Fin Tube is a type of heat exchanger tube that has fins attached to its outer surface using high-frequency welding technology. The fins are typically made from the same material as the tube (stainless steel) and are welded to increase the surface area for heat transfer, improving the efficiency of heat exchange processes.

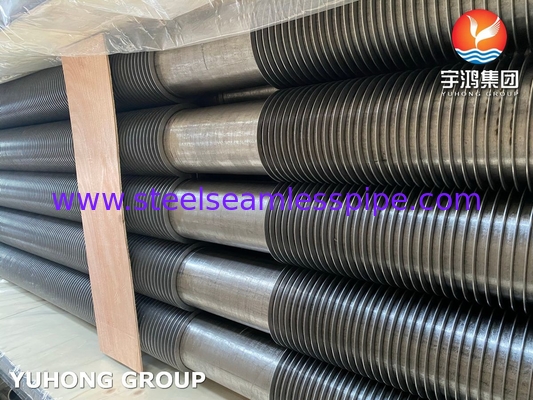

Stainless steel High-Frequency Welded (HFW) fin tubes are used in heat exchangers, boilers, and other applications where efficient heat transfer is required. These tubes are made by helically winding a strip of stainless steel fin around a stainless steel tube and welding it in place using high-frequency induction welding.

Material: The base tube and fins are made from stainless steel, providing excellent corrosion resistance, mechanical strength, and thermal conductivity.

Fin Type: The fins are helically wound around the tube, increasing the surface area for heat exchange.

Welding Method: High-frequency welding ensures a strong bond between the tube and the fins, improving the efficiency and durability of the tube.

Applications: Commonly used in industries such as power generation, petrochemical, oil and gas, and HVAC (heating, ventilation, and air conditioning).

Benefits:

1.Durability: Resistant to high temperatures and corrosive environments.

2.Efficiency: Enhanced heat transfer due to increased surface area.

3.Strength: Robust construction ensures long service life even under demanding conditions.

4.Specifications:

Tube Diameter: Varies based on application requirements.

Fin Height and Thickness: Customizable to suit specific heat transfer needs.

Length: Can be manufactured to specified lengths depending on the heat exchanger design.

Advantages

-

Enhanced Heat Transfer Efficiency:

- The fins increase the surface area of the tube, allowing for more efficient heat exchange between the fluid inside the tube and the external environment.

-

Corrosion Resistance:

- Stainless steel provides excellent resistance to corrosion and oxidation, making the fin tubes suitable for use in harsh and corrosive environments.

-

High Strength and Durability:

- Stainless steel HFW fin tubes can withstand high temperatures and pressures, providing long service life and reducing the need for frequent replacements.

-

Improved Thermal Conductivity:

- The high-frequency welding ensures a strong bond between the fins and the tube, enhancing thermal conductivity and ensuring efficient heat transfer.

-

Reduced Maintenance Costs:

- The durability and corrosion resistance of stainless steel reduce the need for regular maintenance and replacement, lowering the overall operational costs.

-

Flexibility in Design:

- HFW technology allows for the customization of fin shapes, sizes, and spacing to meet specific application requirements.

Manufacturing process

The fin strip is welded continuously and spirally wound onto a polished bare tube. And the tube and fins are bonded together by using high frequency resistance welding technique.

Applications

-

Power Generation:

- Used in boilers, economizers, and heat exchangers to improve the efficiency of steam generation and power production processes.

-

Petrochemical and Chemical Industries:

- Employed in heat exchangers, reboilers, and condensers to handle high-temperature, high-pressure, and corrosive fluids.

-

HVAC Systems:

- Utilized in air conditioners, condensers, and evaporators to enhance heat transfer in heating, ventilation, and air conditioning systems.

-

Food and Beverage Industry:

- Applied in processes requiring efficient heat transfer with strict hygiene standards, such as pasteurization and refrigeration.

-

Pharmaceutical Industry:

- Used in sterilizers, reactors, and heat exchangers where high cleanliness and corrosion resistance are critical.

-

Desalination Plants:

- Implemented in heat exchangers for seawater desalination processes, benefiting from the corrosion resistance of stainless steel.

-

Waste Heat Recovery Systems:

- Integrated into systems that recover and utilize waste heat from industrial processes, improving overall energy efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!