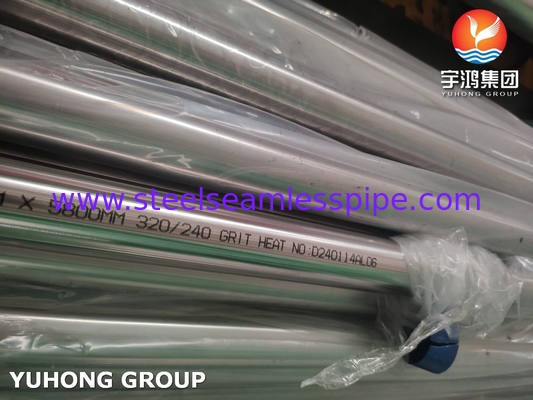

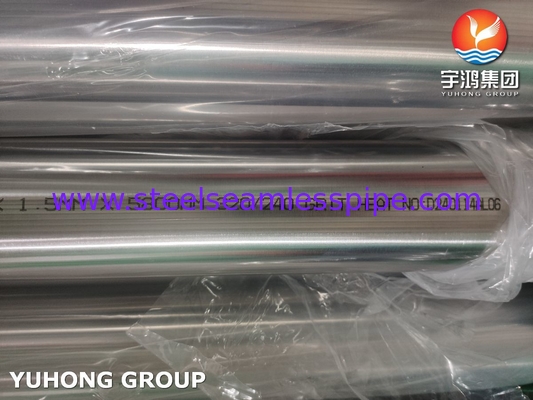

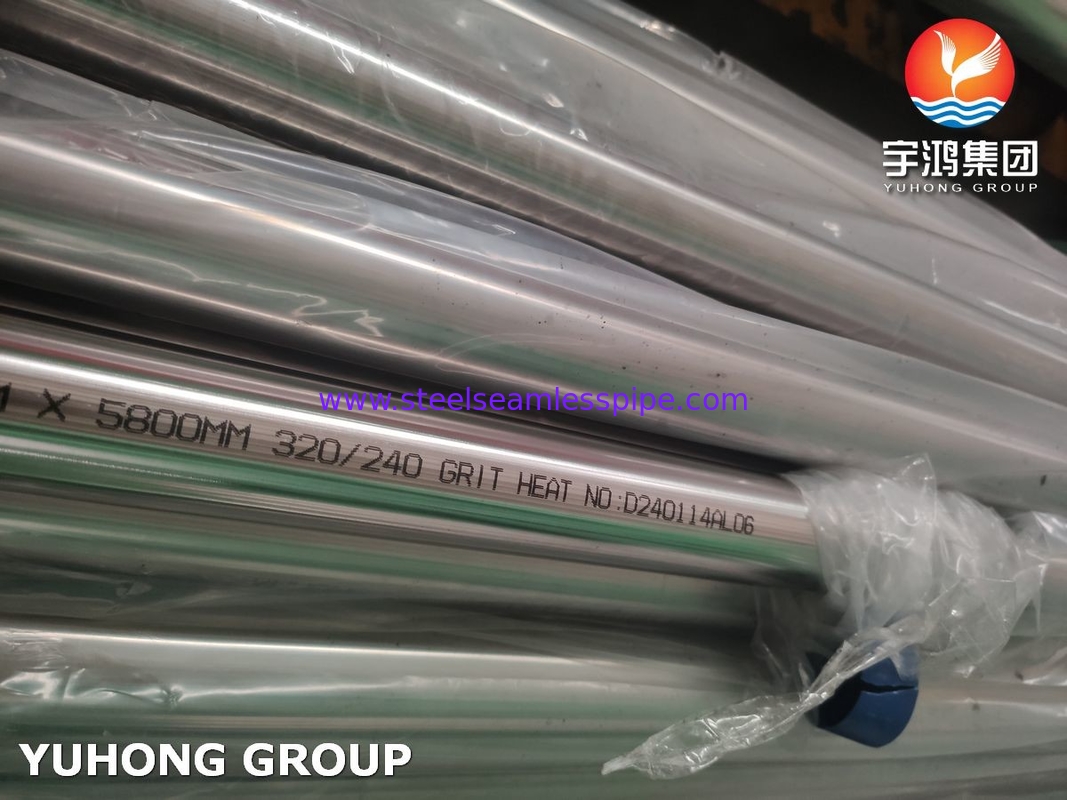

ASTM A270 TP304 Stainless Steel Sanitary Tubing Inside and Outside Polished 320/240 Grit

The ASTM A270 specification outlines the requirements for seamless and welded austenitic and ferritic stainless steel sanitary tubing intended for use in the dairy and food industry and having special surface finishes. Compliance with this standard ensures that the tube meets specific quality and cleanliness criteria. The ASTM A270 standard specifies that the sanitary tube must have a polished finish both inside and outside. The surface finish helps to reduce the risk of bacterial growth and makes the tube easier to clean and maintain sanitary conditions.

ASTM A270 Sanitary Stainless Steel Tube Size Range

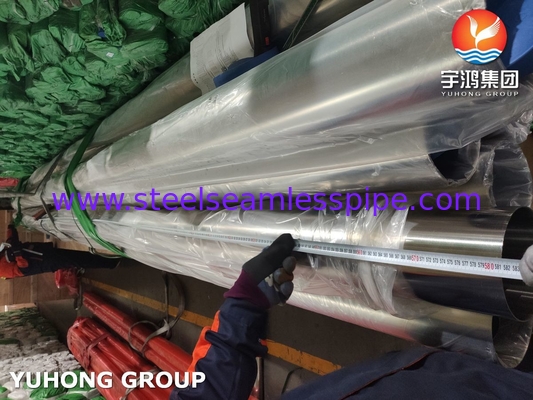

ASTM A270 sanitary stainless pipe usually refers to the small pipe diameters, normally from 1/2” to 2 1/2”, thickness from 0.049 in (1.24mm) to 0.15 in (3.81mm). Length can be fixed or random

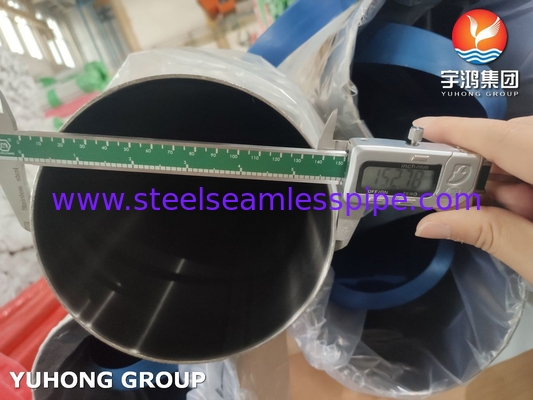

The maximum outer diameter of ASTM A270 tubing is 12 inches (304.8 mm).

ASTM A270 tubing using inch-pound as the standard unit of measure.

Wall thickness tolerance shall not vary more than 12.5%.

|

Tolerance

|

a) Outer Diameter: +/- 0.2mm |

| b) Thickness: +/- 0.02mm |

| c) Length: +/- 5mm |

| End |

PE/Plain Ends, BE/Beveled Ends |

| Technique |

cold drawn |

| Application |

chemical industry, decoration, building, Food plant, etc. |

| Test |

Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

ASTM A270 TP304 SS Tube Chemical Composition

| Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

| 304 |

min. |

– |

– |

– |

– |

– |

18.0 |

– |

8.0 |

– |

| max. |

0.08 |

2.0 |

0.75 |

0.045 |

0.030 |

20.0 |

|

10.5 |

0.10 |

ASTM A270 TP304 SS Tube Mechanical Properties

| Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

| Rockwell B (HR B) max |

Brinell (HB) max |

| 304 |

515 |

205 |

40 |

92 |

201 |

Equivalent Grade of ASTM A270 TP304 SS Tube

| Grade |

UNS No |

Old British |

Euronorm |

Swedish SS |

Japanese JIS |

| BS |

En |

No |

Name |

| 304 |

S30400 |

304S31 |

58E |

1.4301 |

X5CrNi18-10 |

2332 |

SUS 304 |

Dimensional Tolerences

all dimensions in inches (mm)

| Size OD |

Nominal Wall |

Outside Diameter |

Length |

Wall |

| |

| 1/2" (12.7) |

0.065" (1.65)/0.049" (1.25) |

+/-0.005 (0.13) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 3/4" (19.1) |

0.065" (1.65)/0.049" (1.25) |

+/-0.005 (0.13) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 1" (25.4) |

0.065" (1.65)/0.049" (1.25) |

+/-0.005 (0.13) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 1-1/2" (38.1) |

0.065" (1.65)/0.049" (1.25) |

+/-0.008" (0.20) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 2" (50.8) |

0.065" (1.65)/0.049" (1.25) |

+/-0.008" (0.20) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 2-1/2" (63.5) |

0.065" (1.65) |

+/-0.010" (0.25) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 3" (76.2) |

0.065" (1.65) |

+/-0.010" (0.25) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 4" (101.6) |

0.083" (2.11) |

+/-0.015" (0.38) |

+1/8" (3.18) - 0 |

+/-10.0% |

| 6" (152.4) |

0.083" (2.11) |

+/-0.030" (0.76) |

+1" (25.4) - 0 |

+/-10.0% |

| 6" (152.4) |

0.109" (2.77) |

+/-0.030" (0.76) |

+1" (25.4) - 0 |

+/-10.0% |

| 8" (203.2) |

0.109" (2.77) |

+0.061" (1.55)/-0.031" (0.79) |

+1" (25.4) - 0 |

+/-10.0% |

In addition to the polished finish specified by the ASTM A270 standard, some manufacturers offer electropolishing as an additional surface treatment for sanitary tubes. Electropolishing is an electrochemical process that smooths and streamlines the metal surface at a microscopic level, further enhancing the corrosion resistance and cleanability of the tube. This extra step can be particularly beneficial in applications where outstanding surface finish is essential for maintaining the highest levels of hygiene.

Application

1. Food and beverage industry: It is used in the production of dairy, food, and beverage products where sanitation and cleanliness are of utmost importance.

2. Pharmaceutical industry: The sanitary tube is used in the manufacturing of pharmaceutical products to ensure the purity and sterility of the production environment.

3. Biotechnology industry: In biotech applications where maintaining aseptic conditions is crucial, such as in the production of biopharmaceuticals and other biological products.

4. Water treatment and distribution: The tube is utilized in sanitary piping systems for transporting potable water, where maintaining sanitary conditions is essential to prevent contamination.

5. Commercial and industrial applications: It's also used in various commercial and industrial settings where clean and hygienic conditions are required, such as in clean rooms, laboratories, and certain manufacturing processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!