ASTM A312 TP347 Stainless Steel Serreted Spiral HFW(High Frequency Welding) Finned Tube

What is serrated spiral high frequency welding finned tube?

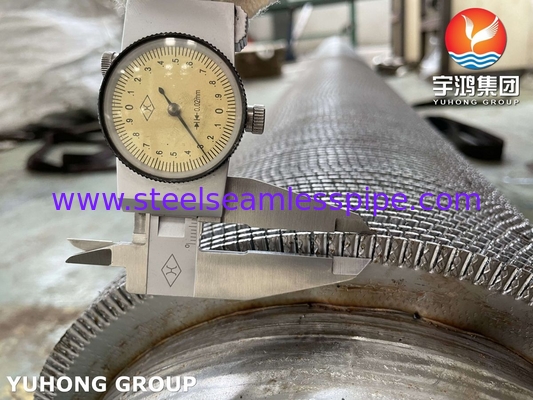

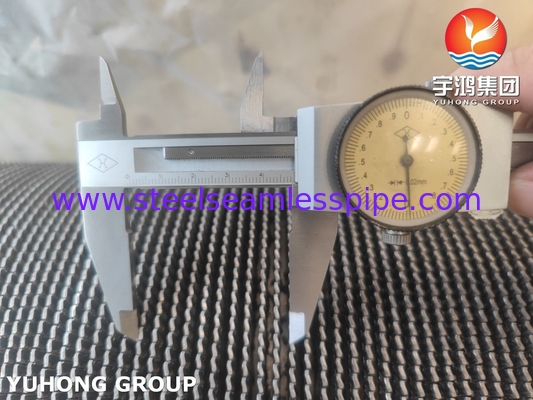

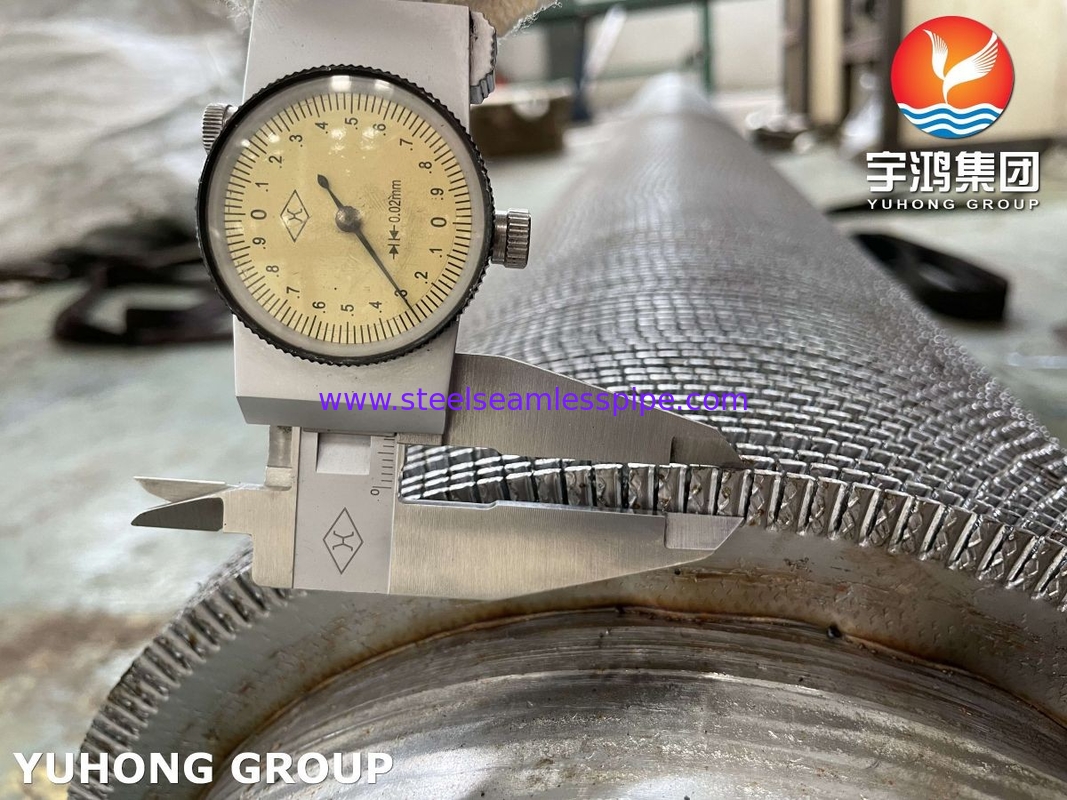

Serrated spiral high frequency welding finned tube is a type of heat transfer equipment that consists of a base tube and an extended surface in the form of fins. The tube is designed with a serrated surface, which maximizes the contact area between the fins and the base tube. The fins are spiral wound around the tube and welded to the tube by high-frequency welding. This type of finned tube provides enhanced heat transfer performance due to the increased surface area, while the serrated surface improves the turbulence of the fluid flow, which further increases the heat transfer coefficient. The spiral shape of the fins provides superior mechanical strength and eliminates the risk of fluttering or vibration. The high-frequency welding process ensures consistent and durable bonding between the fins and the base tube, resulting in a reliable and long-lasting heat transfer solution.

The following are some of the characteristics of serrated spiral high frequency welding finned tube:

1. Enhanced heat transfer performance: The extended surface area provided by the fins increases the heat transfer coefficient, allowing for efficient heat transfer.

2. Improved fluid flow: The serrated surface on the tube promotes turbulent fluid flow, further increasing the heat transfer coefficient.

3. High mechanical strength: The spiral winding of the fins provides greater mechanical strength, reducing the risk of vibration or fluttering.

4. Durable and reliable: The high-frequency welding process used to bond the fins to the base tube creates a consistently strong bond that can withstand harsh conditions, resulting in a durable and reliable heat transfer solution.

5. Versatile: The serrated spiral high frequency welding finned tube is suitable for a wide range of industries and applications, including power generation, petrochemical processing, and HVAC systems.

Chemical composition of ASTM A312 TP347

| ASTM A312 |

Mn |

Si |

C |

Ni |

P |

S |

Cr |

Mo |

N |

| TP347 |

min. |

- |

- |

- |

9.0 |

- |

- |

17.0 |

2.00 |

- |

| max. |

2.0 |

1.00 |

0.08 |

13.0 |

0.045 |

0.030 |

20.0 |

3.00 |

- |

Mechanical Properties of ASTM A312 TP347

| Grade |

Tensile Strength (MPa) min |

Elongation (% in 50mm) min |

Yield Strength 0.2% Proof (MPa) min |

Hardness |

| Rockwell B (HR B) max |

Brinell (HB) max |

| SS 347 |

515 |

40 |

205 |

92 |

201 |

Equivalent Grades of ASTM A312 TP347

| GRADE |

UNS |

WERKSTOFF NR. |

JIS |

AFNOR |

BS |

GOST |

EN |

SS |

| |

USA |

GERMAN |

JAPAN |

RUSSIAN |

BRITISH |

RUSSIAN |

EUROPE |

SWEDISH |

| ASTM A312 347 |

S34700 |

1.4550 |

- |

- |

- |

- |

X6CrNiNb18-10 |

- |

Serrated spiral high frequency welding finned tubes are used in various industries and applications, including:

1. Heat exchangers: They are used in heat exchangers to transfer heat between two fluids. The high heat transfer coefficient of the finned tubes ensures efficient heat transfer.

2. Boilers: They are used in boilers to increase the heating surface area, thereby improving the boiler's efficiency.

3. Petrochemical processing: They are used in the processing of petrochemicals to transfer heat from hot gases or liquids to cooler fluids.

4. Power generation: They are used in power generation applications, such as thermal power plants, to transfer heat from the steam to the cooling water.

5. HVAC systems: They are used in HVAC systems, such as air-cooled chillers, to increase the heat transfer surface area and improve the system's efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!