Carbon Steel U Bend Tube, ASME SA179, Full Killed, Nace MR-0175, For Heat Exchanger Application

YUHONG GROUP deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy ,Monel, Inconel, Incoloy ) seamless and welded pipe and tube already more than 35 years, every year sell more than 80000 tons of steel pipe and tube. Our client already cover more than 85 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Korea, Singapore, Austrial, Poland, France , ....And our group branch companies and factories have been already approved: CE, TUV, LR, ABS, DNV, GL, BV, KR, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2015, ISO 14001-2015, ISO 18001-2015, ISO 45001-2015.

ASTM A178/A178M-19:Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon- Manganese Steel Boiler and Superheater Tubes;

ASTM A179/A179M-19:Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes;

ASTM A192/A192M-17:Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service;

ASTM A210/A210M-19:Standard Specification for Seamless Medium-Carbon Steel Boiler and Superheater Tubes;

ASTM A333/A333M-18:Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness;

ASTM A334/A334M-04a:Standard Specification for Seamless and Welded Carbon and Alloy-Steel Tubes for Low-Temperature Service;

ASTM A370/A370M-23:Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM A450/A450M-23:Standard Specification for General Requirements for Carbon and Low Alloy Steel Tubes;

ASME SA178/SA178M-23: specification covers minimum-wall-thickness,electric-resistance-welded tubes made of carbon steel and carbon-manganese steel intended for use as boiler tubes, boiler flues, superheater flues;

ASME SA179/SA179M-23:Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes;

ASME SA210/SA210M-23:Specification for Seamless Medium Carbon Steel Boiler And Superheater Tubes;

ASME SA333/SA333M-23:Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness;

ASME SA334/SA334M-23:Standard Specification for Seamless and Welded Carbon and Alloy-Steel Tubes for Low-Temperature Service;

ASME SA450/SA450M-23:Specification for General Requirements for Carbon and Low Alloy Steel Tubes;

| Carbon |

Chromiun |

Low Temperature |

Stainless Steel |

Duplex |

Copper& Bronze |

Titanium |

Ni-Alloy |

| SA178-A |

SA213-T1 |

SA333-Gr.1 |

SA213 |

TP316L |

A789-S31803 |

SB111-C70600 |

SB338-GR.1 |

SB163 |

NO2200 |

| SA178-C |

SA213-T11 |

SA333-Gr.3 |

SA249 |

TP316H |

A789-S32205 |

SB111-C71500 |

SB338-GR.2 |

SB167 |

NO2201 |

| SA179 |

SA213-T12 |

SA333-Gr.6 |

SA268 |

TP316Ti |

A789-S32750 |

SB111-C71640 |

SB338-GR.5 |

SB444 |

NO8020 |

| SA192 |

SA213-T22 |

SA333-Gr.7 |

SA269 |

TP316LN |

A789-S32760 |

SB111-C68700 |

SB338-GR.7 |

SB514 |

NO6022 |

| SA209-T1 |

SA213-T5 |

SA333-Gr.8 |

SA376 |

TP321 |

A789-S32707 |

SB111-C44300 |

SB338-GR.9 |

SB619 |

N10276 |

| SA209-T1a |

SA213-T9 |

SA334-Gr.1 |

TP304 |

TP321H |

A789-S32304 |

|

SB338-GR.12 |

SB622 |

NO4400 |

| SA209-T1b |

SA213-T91 |

SA334-Gr.3 |

TP304L |

TP347 |

A789-S31500 |

|

|

SB626 |

NO6600 |

| SA210-A1 |

|

SA334-Gr.6 |

TP304H |

TP347H |

S31254 |

|

|

SB674 |

NO6601 |

| SA210-C |

|

SA334-Gr.7 |

TP304N |

TP405 |

254MA |

|

|

SB677 |

NO6625 |

| SA214 |

|

SA334-Gr.8 |

TP310H |

TP409 |

17-4PH |

|

|

SB704 |

NO690 |

| SA513 MT 1010 |

|

|

TP310S |

TP410 |

17-7PH |

|

|

SB705 |

NO8800 |

| SA513 MT 1015 |

|

|

TP309S |

TP430 |

15-7PH |

|

|

N1001 |

NO8810 |

| SA513 MT 1020 |

|

|

TP317 |

TP439 |

32900 |

|

|

N10665 |

NO8811 |

| |

|

|

TP317L |

TP444 |

|

|

|

N10675 |

NO8825 |

| |

|

|

TP348 |

TP446 |

|

|

|

TP904L |

|

| |

|

|

TP347HFG |

|

|

|

|

|

|

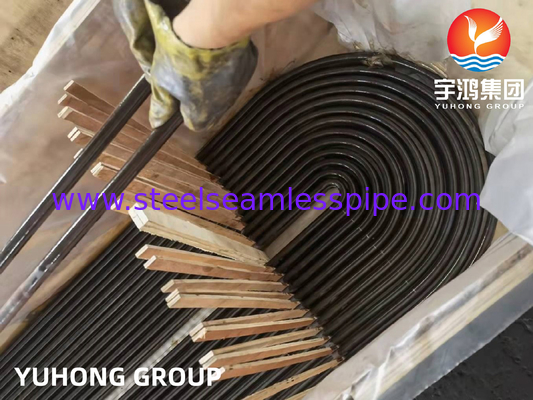

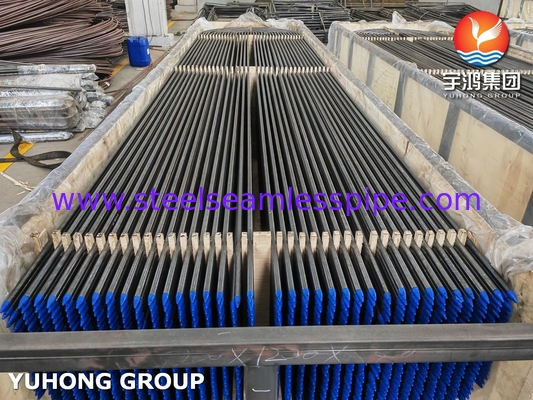

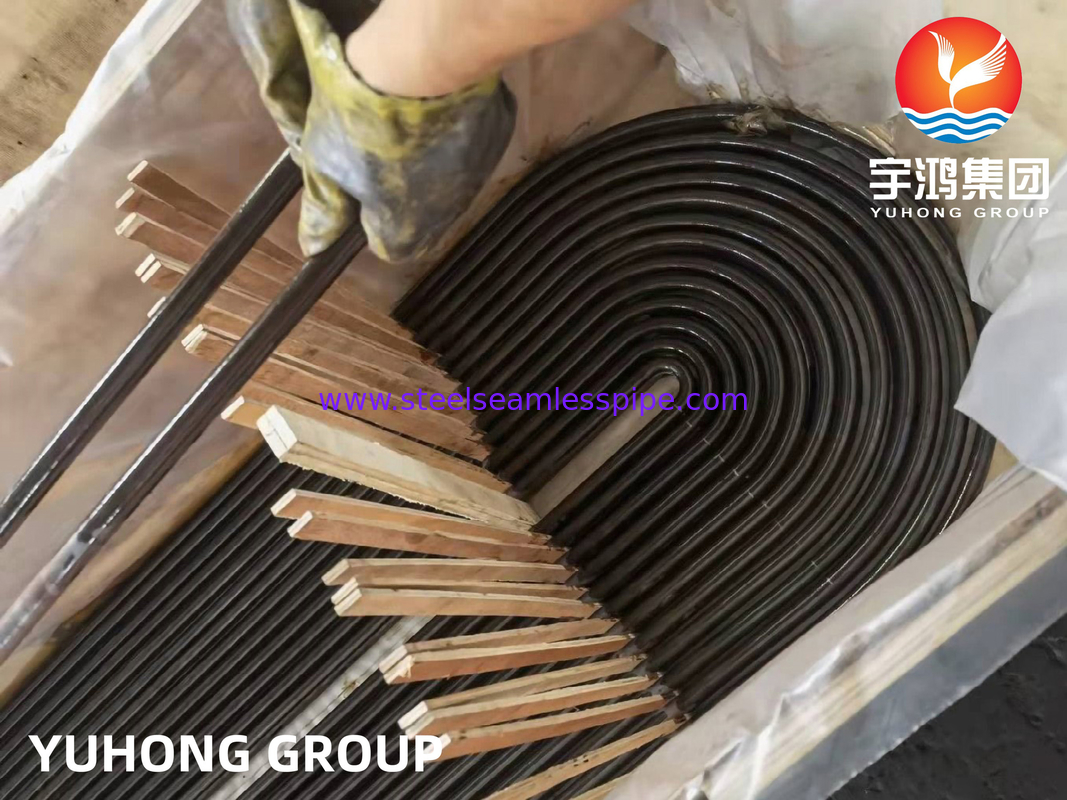

U-Bend Tubes:

1.TEMA RCB 2.31:Standard Of The Tubular Exchanger Manufacturers Association (9th Edition).

2. ASTM A688 / ASME SA688: Standard Specification For Welded Tubes Of Austenitic Corrosion Resistant Steel Grade Designed For Feed Water Boilers.

3. ASTM B163 /ASME SB163: Standard Techinical Requirements For Tubes Of Nickel And Nickel Alloy For Condensers And Heat Exchangers.

Bending Radius: From 1.5*OD(Outside Diameter) To 3600mm, we also make snake bending tube;

Straight Tubes Maximum Length:Before Bending Max.: 35000 mm/pc.

Leg Length: Min.: 0.3 Meter, Max.:16500 mm (For Max R=3500mm)

Note: Other Size Are Available Upon Agreement.

Heat Treatment: Stress Relieved After U Bending (Bending Area Plus 300MM For Each Leg).

Hydrostatic Test After U Bending: Maximum Test Pressure 10Mpa / Soaking time: 10 Sec. With Dematerialized Water And Compressed Air Cleaning After Hydro-Test.

Packaging: In Strong Transport-Worthy Pre-fumigated wooden boxes of corresponding dimensions for each tube Length, Radius, Diameter, According To PO requirements as well as wrapped In polyethylene

films With soft plastic caps on both end of Tube.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!