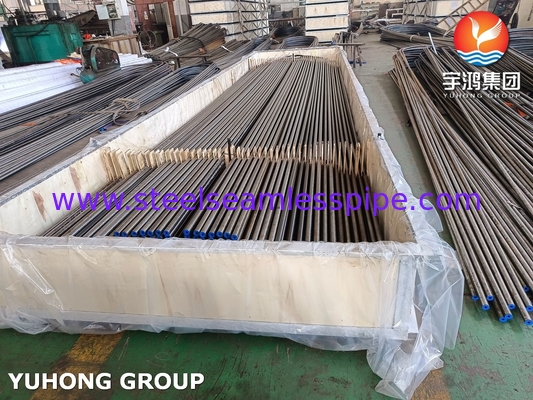

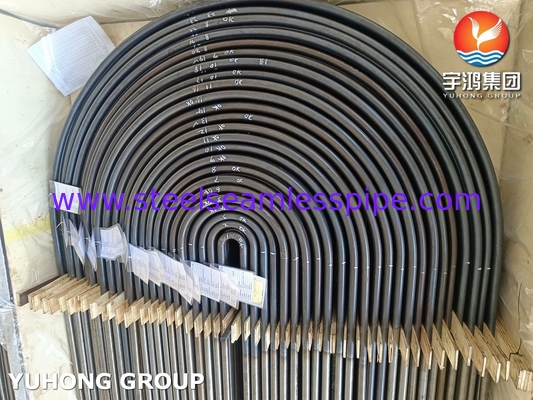

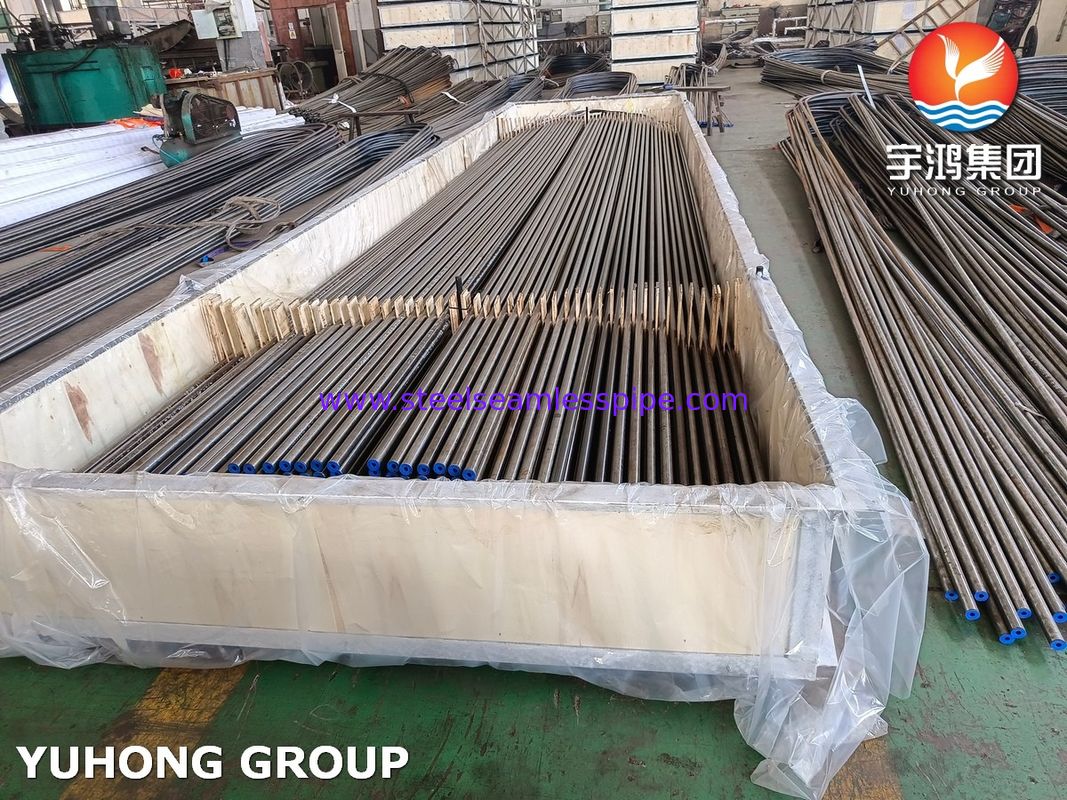

ASTM A179 Carbon Steel Seamless U Bend Tube Heat Exchanger Tube

ASTM A179 provide a balance of affordability, strength, and performance, making them an effective choice for many heat exchanger applications! It's important to assess the specific operating environment and chemical exposure to determine if they are the best choice for a given application in industries like power generation, oil and gas, and HVAC systems, where they are used in low-pressure heat exchangers and condensers. The U-bend configuration allows for greater packing density, enabling heat exchangers to occupy less space while maintaining a high surface area for heat transfer. This is particularly beneficial in applications where space is limited.

A179 Carbon Steel Seamless Tube Chemistry Composition:

|

C, %

|

Mn, %

|

P, %

|

S, %

|

|

0.06-0.18

|

0.27-0.63

|

0.035 max

|

0.035 max

|

A179 Carbon Steel Seamless Tube Mechanical Properties:

|

Tensile Strength, MPa

|

Yield Strength, MPa

|

Elongation, %

|

Hardness, HRB

|

|

325 min

|

180 min

|

35 min

|

72 max

|

A179 Carbon Steel Seamless Tube Outside Diameter & Tolerance

| Outside Diameter, mm |

Tolerance, mm |

| 3.2≤OD<25.4 |

±0.10 |

| 25.4≤OD≤38.1 |

±0.15 |

|

38.1<OD<50.8

|

±0.20 |

| 50.8≤OD<63.5 |

±0.25 |

| 63.5≤OD<76.2 |

±0.30 |

| 76.2 |

±0.38 |

A179 Carbon Steel Seamless Tube Wall thickness & Tolerance

| Outside Diamter, mm |

Tolerance, % |

| 3.2≤OD<38.1 |

+20/-0 |

| 38.1≤OD≤76.2 |

+22/-0 |

Heat exchangers are critical components in various industries, and the material choice for the tubes plays a significant role in their performance and durability. Here are some common materials used for heat exchanger tubes:

1. Carbon Steel

ASTM A179/A192: Commonly used for low-pressure applications where higher corrosion resistance is not critical. Carbon steel is cost-effective and provides good mechanical strength.

2. Stainless Steel

Types 304, 316, and 321: Stainless steel tubes are widely used for their excellent corrosion resistance, especially in harsh environments and where hygiene is essential (like food processing).

Duplex Stainless Steel: Offers high strength and resistance to both pitting and stress corrosion, making it suitable for more demanding applications.

3. Copper

Copper Alloys: Copper and its alloys (like brass and bronze) are used for their excellent thermal conductivity. They are common in beverage and HVAC applications but can be prone to corrosion in certain environments.

4. Titanium

Titanium Alloys: Preferred in highly aggressive environments, such as seawater or chemical processing, due to their excellent corrosion resistance and strength-to-weight ratio.

5. Aluminum

Aluminum Alloys: Lightweight and offers good thermal conductivity. Used in applications with lower pressure requirements, like automotive heat exchangers.

6. Nickel Alloys

Inconel and Monel: Used for extreme environments or where high temperatures and corrosion are concerns. They are more expensive but provide exceptional performance.

7. Copper-Nickel Alloys

CuNi 90/10, CuNi 70/30: Common in marine applications due to their resistance to seawater corrosion and biofouling.

8. Specialty Alloys

Hastelloy, Alloy 20: Used in chemical processing industries or environments that involve aggressive chemicals and high temperatures.

Applications

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!