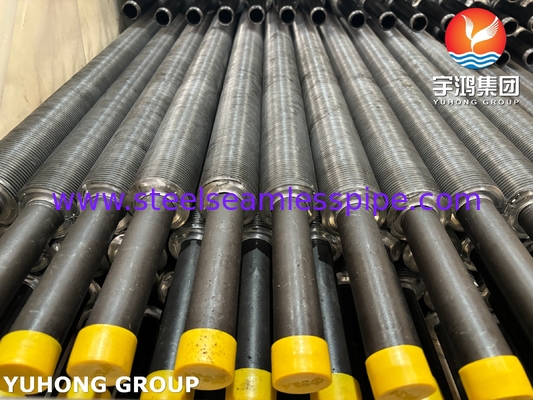

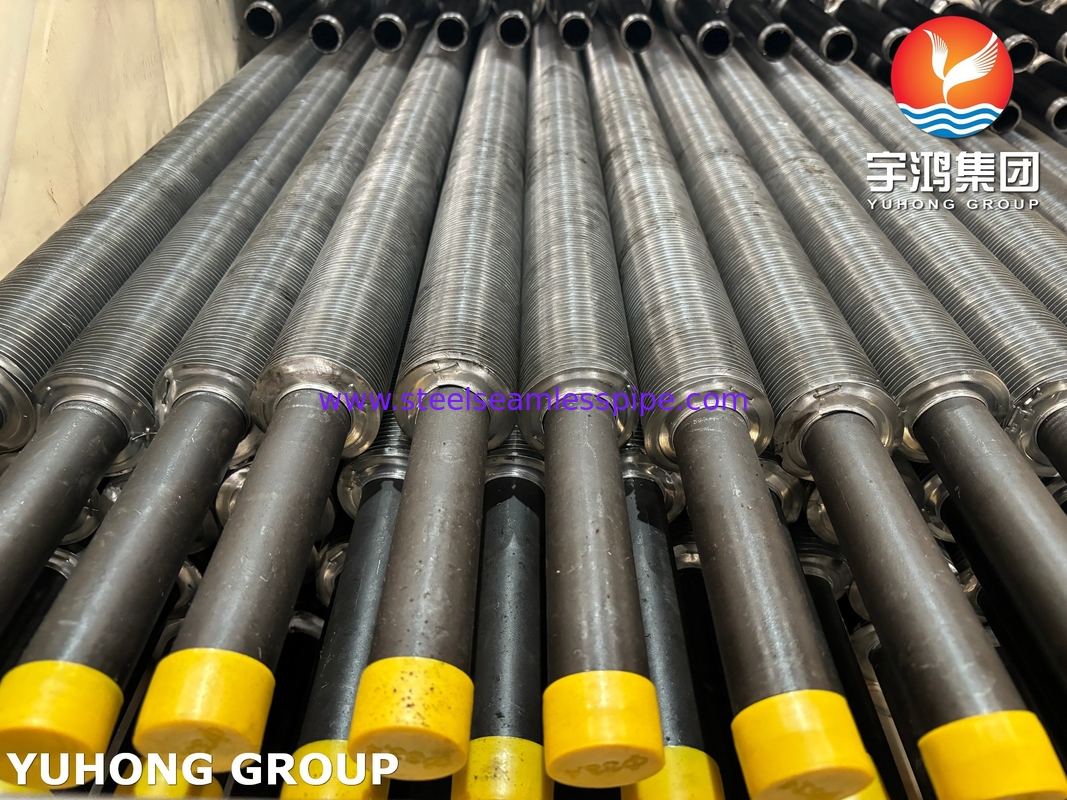

Carbon Steel ASTM A179 L Type Fin Tube For Heat Exchanger And Industry

Overview:

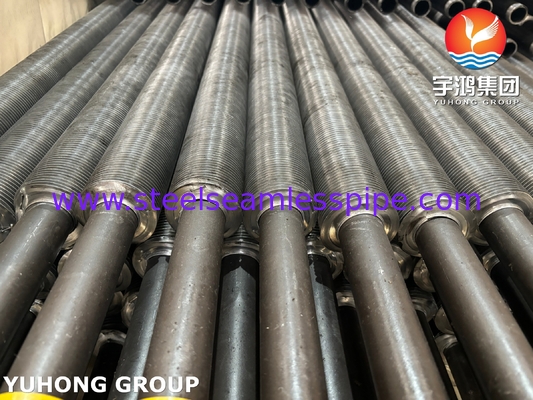

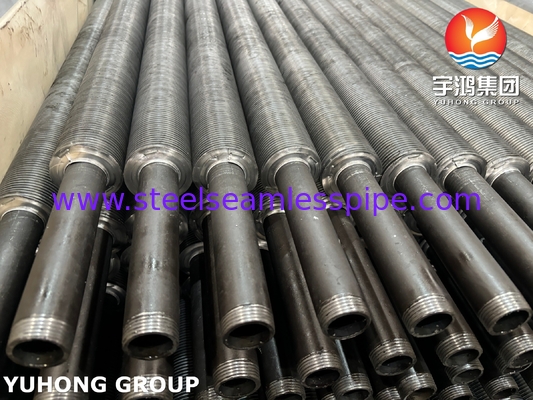

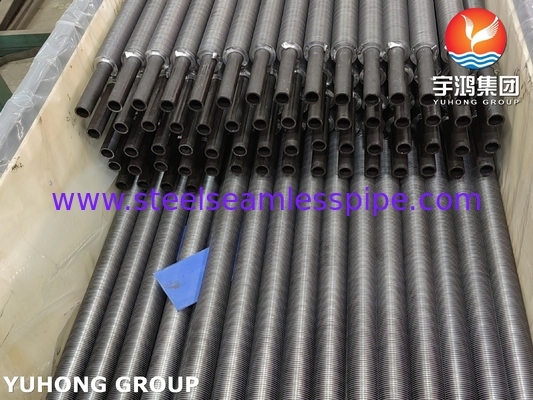

In an "L" type fin tube (also called an "L" foot fin tube), the fins are constructed by spirally winding the fin material around a base tube, hence the name spirally wound fin tube. The base of the fin tube is molded into an "L" shape. This design not only provides a solid base for the fins, but also provides some protection against atmospheric corrosion.

L-fin tubes are designed for efficient heat transfer. Their trapezoidal shape is formed during the calendering process, which ensures optimal heat flow by tightly bonding the fins to the tube, minimizing thermal resistance. This design maintains uniform fin spacing for efficient thermal performance.

Key features include:

High temperature resistance: Withstands temperatures up to 230°C without atmospheric corrosion or thermal stress.

Corrosion protection: The contact area between the fin strips and the tube surface protects the tube wall from atmospheric corrosion.

Cost-effective design: This L-type configuration is more economical compared to other designs such as LL, KL or G-embedded.

The L-type finned tube provides the contact area between the fin strip and the tube surface, protecting the tube wall from atmospheric corrosion.

The tube can withstand temperatures up to 150°C and there is no risk of atmospheric corrosion or thermal stress.

Base tube material:

stainless steel, carbon steel, copper alloy,alloy steel (No theoretical limit)

ASME SA213/ASTM A213 TP304/304L TP316/TP316L TP321 TP310S TP317,

ASME SA106/ASTM A106 Gr B Gr C,ASME SA179/ASTM A179,ASME SA192/ASTMA192

ASTM B111 C70600 C44300 C68700 C71500...

Fin material: Aluminium,copper

A179 Chemical Composition

| Element |

A/SA 179 |

| C |

0.06-0.18 |

| Mn |

0.27-0.63 |

| P |

≤0.035 max |

| S |

≤0.035 max |

ASTM A179 Material Properties

|

Element

|

A/SA 179

|

|

Tensile Strength KSI (MPa)

|

47 (325)

|

|

Yield Strength KSI (MPa)

|

47 (325)

|

|

Elongation min. %

|

35

|

Equivalent Material:

| Grade |

ASTM A179 / ASME SA179 |

| UNS No |

K01200 |

| Old British |

BS |

CFS 320 |

| German |

No |

1629 / 17175 |

| Number |

1.0309 / 1.0305 |

| Belgian |

629 |

| Japanese JIS |

D3563 / G3461 |

| French |

A49-215 |

| Italian |

5462 |

Applications:

Heat exchangers in power plants

Steam condensation systems

Chemical and petrochemical industries

Food processing plants and refrigeration technology

Industry (steel mills, incinerators, gas compression facilities)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!