Welded Helical Spiral Serrated Finned Tube , HFW Fin Tube For Heat Exchanger

Overview

HFW (High-Frequency Welded) Fin Tubes are heat exchanger components consisting of a base tube with externally welded fins. The fins are bonded to the tube using a high-frequency electric current, creating a robust metallurgical bond. This design maximizes surface area for efficient heat transfer in applications such as boilers, air coolers, and economizers.

-

-

Tube Material:

The main tube is typically made of materials such as carbon steel, stainless steel, or other alloys, depending on the specific requirements of the application.

Fins:

The fins are spiral and serrated, which means they are helically wound around the outer surface of the main tube, forming a continuous spiral pattern. The serrations add turbulence to the air or gas flow, improving heat transfer.

Welding Process:

The fins are welded to the outer surface of the main tube. Welding ensures a strong and durable bond between the tube and the fins, allowing for efficient heat transfer.

Helical Configuration:

The helical configuration of the fins provides a larger surface area for heat exchange compared to straight fins. This increased surface area enhances heat transfer efficiency.

Serrated Design:

The serrated edges on the fins create turbulence in the fluid or gas flowing over them. This turbulence disrupts the boundary layer and promotes better heat transfer between the tube surface and the fluid or gas.

Heat Transfer Efficiency:

The combination of helical fins and serrated edges improves heat transfer efficiency by preventing the formation of a stagnant boundary layer on the fin surface. This design is especially effective in applications where high-efficiency heat exchange is required.

-

Use Cases:

-

Air-cooled heat exchangers (ACHEs).

-

Fired heaters, boilers, and condensers.

-

Corrosive environments (e.g., offshore platforms, chemical plants) when paired with stainless steel or duplex materials.

-

Advantages

-

Efficiency: Enhanced heat transfer due to large surface area.

-

Durability: Strong weld joints resist thermal cycling and mechanical stress.

-

Corrosion Resistance: Optional materials (e.g., SS 316L, super duplex) for harsh conditions.

-

Customization: Tailored fin geometry (pitch, shape) for specific thermal performance.

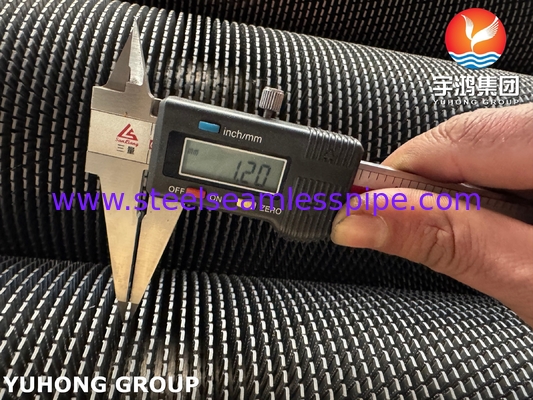

Base Tube Details Tubes Diameter Range

15.88 mm to 219 mm Tubes Thickness Range: 1.651 mm to 16mm Tube Material: Carbon Steel Seamless Tubes, Stainless Steel, Carbon Alloy Steel, Corten steel, duplex stainless Steel, Super Duplex Stainless Steel S32750, Inconel Alloy, High Chrome High Nickle Incoloy alloy, CK 20 material and some other material. Fin Details Fins Thickness : Min. 0.8 mm to Max. 4 mm Fins Height: Min 0.25” (6.35 mm) To Max.1.5” (38 mm) Fin Density : Min 43 Fins per Meter to Max. 287 Fins per Meter Material : Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, Duplex Steel and Incoloy Alloy.

It adopts high frequency welding spiral technology, the national patent technology with high frequency power supplies as the heat source to heat the steel strip, steel pipe at the same time, yo make its welded together as a whole. This technology has the characteristics as high in thermal efficiency, large heat dissipation area, long service life, range adaptation temperature, high pressure, etc.

The advantages of high frequency welding spiral fin tube

1. The simple and economic installation The maximum length of high frequency welding spiral finned tube can reach 6 meters, that reduces the join points, making the installation more economic, efficient, and also reduces the leakage probability of joints.

2. Easy maintenance After installation, high frequency welding spiral fin tube needs no longer to be maintained.

3. High efficiency The heat dissipation area of high frequency welding spiral fin tube is more than 8 times of the light tube. The internal is smooth, so the internal flow resistance is small.

4. Long service life Fin and pipes with high mechanical strength, so the tensile strength is more than 200 mpa. Both inside and outside of the tube are all made of hot dip galvanized processing. Weldable fin material: carbon steel, stainless steel, alloy steel, corrosion resistant steel.

Applications

- HVAC & Boiler

- Power Plants

- Heat Recovery Steam Generators

- Petrochemical Industries

- Marine Applications

- Refrigeration Applications

- Economizers

- Oil and Gas Coolers

- Plumbing and Air Conditioning

- Condensers and Evaporators

- Shell and Tube Heat Exchange

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!