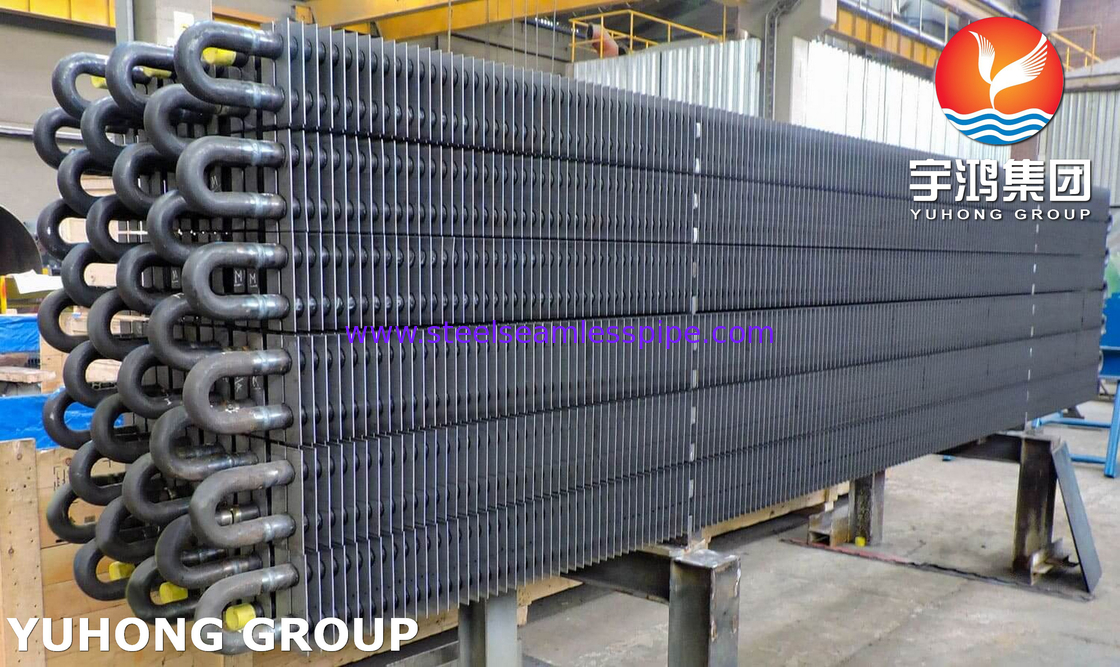

Carbon Steel H Type And Double H Type Fin Tube ASTM A179/ASME SA179

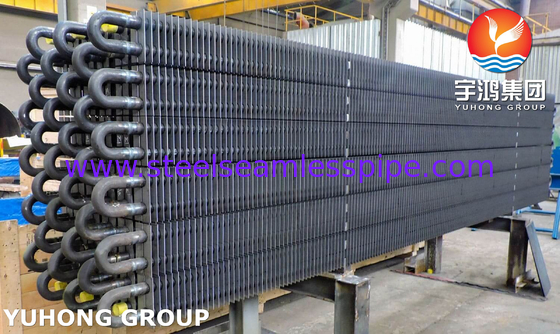

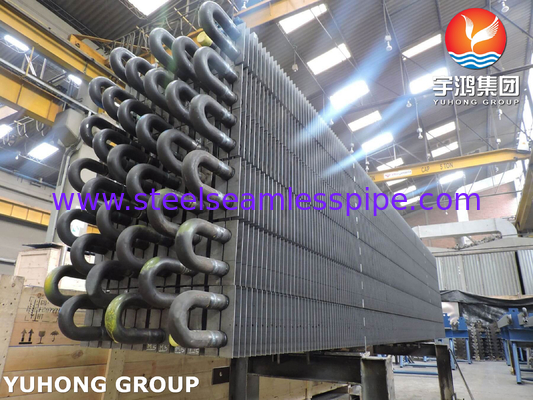

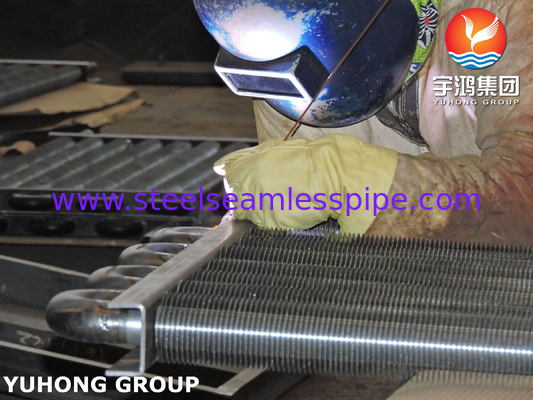

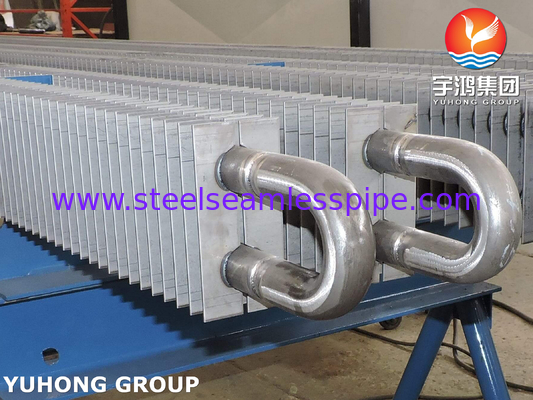

The main differences between H-type fin tubes and double H-type fin tubes are reflected in structure, performance and applicable scenarios. H-type fin tubes form an "H"-shaped cross-section by symmetrically welding two vertical fins on both sides of the base tube. It has a large heat transfer area and medium fluid resistance. It is suitable for conventional high-temperature environments (such as boiler economizers and petrochemical heating furnaces). Its fin spacing is wide, the risk of ash accumulation is low, and it is easy to clean and maintain, with high cost performance.

Double H-type fin tubes superimpose two sets of H-type fins on the base tube to form a "double H" composite structure, which further increases the heat transfer surface area and turbulence effect, and significantly improves the heat transfer efficiency, but the fluid resistance is higher and the structure is more complex, the manufacturing precision requirements are strict, and the cost is high. It is suitable for scenarios with strict requirements on heat exchange efficiency (such as supercritical power generation units and high-temperature cracking furnaces), but the dense fin layout may increase the probability of ash accumulation and requires high-frequency maintenance.

H-type fin tubes are known for their economy and easy maintenance, while double H-type fin tubes have efficient heat transfer as their core advantage. It is necessary to balance performance and cost according to working conditions.

Chemical Composition Requirements

| Element |

Weight Percent |

| C |

0.06~0.18 |

| Mn |

0.27~0.63 |

| P |

≤0.035 |

| S |

≤0.035 |

Mechanical Properties

T.S. min.

ksi [MPa] |

47 [325] |

Y.S. min.

ksi [MPa] |

26 [180] |

El. in 2"

min. % |

35 |

Hardness,

Max. HRB |

72 |

Fin Tube Material

| Bare Tube Materials |

| Carbon Steel Tubes |

A179, A192, SA210 Gr A1/C, A106 Gr B, A333 Gr3 Gr6 Gr8, A334 Gr3 Gr6 Gr8, 09CrCuSb, DIN 17175 St35.8 St45.8, EN 10216 P195 P235 P265, GB/T3087 Gr10 Gr20, GB/T5310 20G 20MnG, |

| Alloy Steel Tubes |

A209 T1 T1a,A213 T2 T5 T9 T11 T12 T22 T91,A335 P2 P5 P9 P11 P12 P22 P91,EN 10216-2 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 |

| Stainless Steel Tubes |

TP304/304L, TP316/TP316L TP310/310S TP347/TP347H |

| Copper Tubes |

UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10 |

| Titanium Tubes |

Gr. 2 |

| Fin materials |

Aluminum (Alu.1100, Alu.1060)

|

Application

H-type finned tubes are widely used in the following scenarios due to their simple structure, economical and practical, and easy maintenance:

Power industry: boiler economizers, air preheaters, used for medium and low temperature flue gas waste heat recovery;

Petrochemical industry: heating furnace convection section, catalytic cracking unit, processing gas with high dust content;

Environmental protection engineering: industrial dust removal equipment, low temperature flue gas waste heat recovery system, suitable for environments that require regular dust cleaning;

Conventional heat exchangers: general heat exchange equipment in chemical, papermaking and other fields, balancing heat transfer efficiency and cost.

Double H-type finned tubes are mainly used in fields with demanding performance requirements:

High-efficiency waste heat recovery: supercritical generator sets, gas turbine exhaust systems, maximize heat energy utilization;

High-temperature and high-pressure environment: petroleum cracking furnaces, synthetic ammonia reactors, withstand high temperatures (≤800°C) and highly corrosive media;

Compact equipment: ships, offshore platforms and other space-constrained scenarios, reduce equipment volume through high-density fins;

High-dust environment (need to cooperate with dust cleaning system): cement kiln exhaust heat exchange, metallurgical industry high-temperature flue gas treatment, enhance heat transfer while controlling dust accumulation risks.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!