1. Material Composition

| Grade |

UNS Designation |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

Other |

| TP321 |

S32100

|

0.08 |

2.00 |

0.045 |

0.03 |

1 |

17.0–19.0 |

9.0–12.0 |

... |

... |

2. Mechanical Properties

- Tensile Strength: ≥515 MPa (75 ksi)

- Yield Strength: ≥205 MPa (30 ksi)

- Elongation: ≥35% (in 50 mm gauge length)

- Hardness: ≤192 HBW (Brinell) or 90 HRB (Rockwell B).

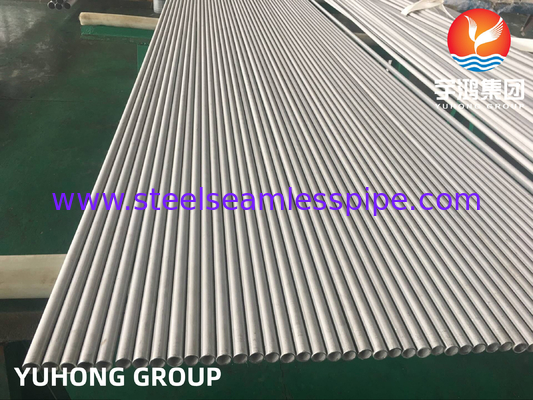

3. Manufacturing & Heat Treatment

Produced via seamless processes (hot extrusion, rotary piercing).

Solution Annealed: Heated to 1040–1120°C followed by rapid cooling to dissolve carbides and optimize corrosion resistance.

4. Applications

- Superheaters & Reheaters:

Operate in steam boilers at 450–700°C, where TP321 resists oxidation and creep deformation.

Titanium stabilization prevents intergranular corrosion during cyclic heating/cooling.

Withstand high-pressure steam (up to 925°C continuous) in coal-fired, nuclear, or biomass plants.

- Ethylene Cracking Furnaces:

Exposed to 800–950°C hydrocarbon streams; TP321 handles thermal cycling and carburization.

- Catalytic Reformer Units:

Resists sulfidation and chloride-induced stress corrosion cracking (SCC) in hydrogen-rich environments.

Used in sour gas or acidic media due to resistance to pitting and general corrosion.

5. Testing & Compliance

Mandatory Tests: Hydrostatic/nondestructive testing, mechanical tests (tensile, hardness), flattening, flaring, and reverse-flange tests.

Certification: Complies with ASME Section II (Materials) and Section I/VIII (Construction). Markings include standard, grade, size, and heat number.

6. Advantages Over Similar Grades

Superior to TP304/304L in high-temperature applications due to titanium stabilization, preventing sensitization.

Unlike TP347 (niobium-stabilized), TP321 offers better weldability and resistance to oxidation in certain conditions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!