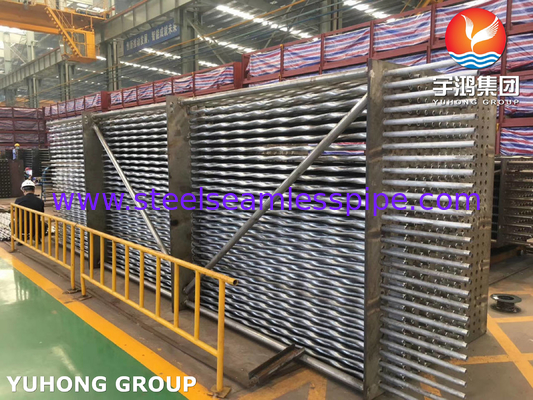

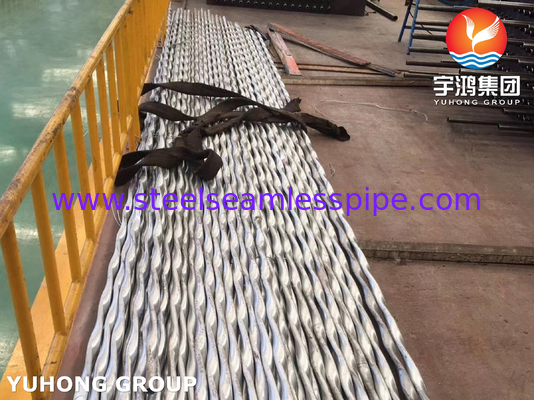

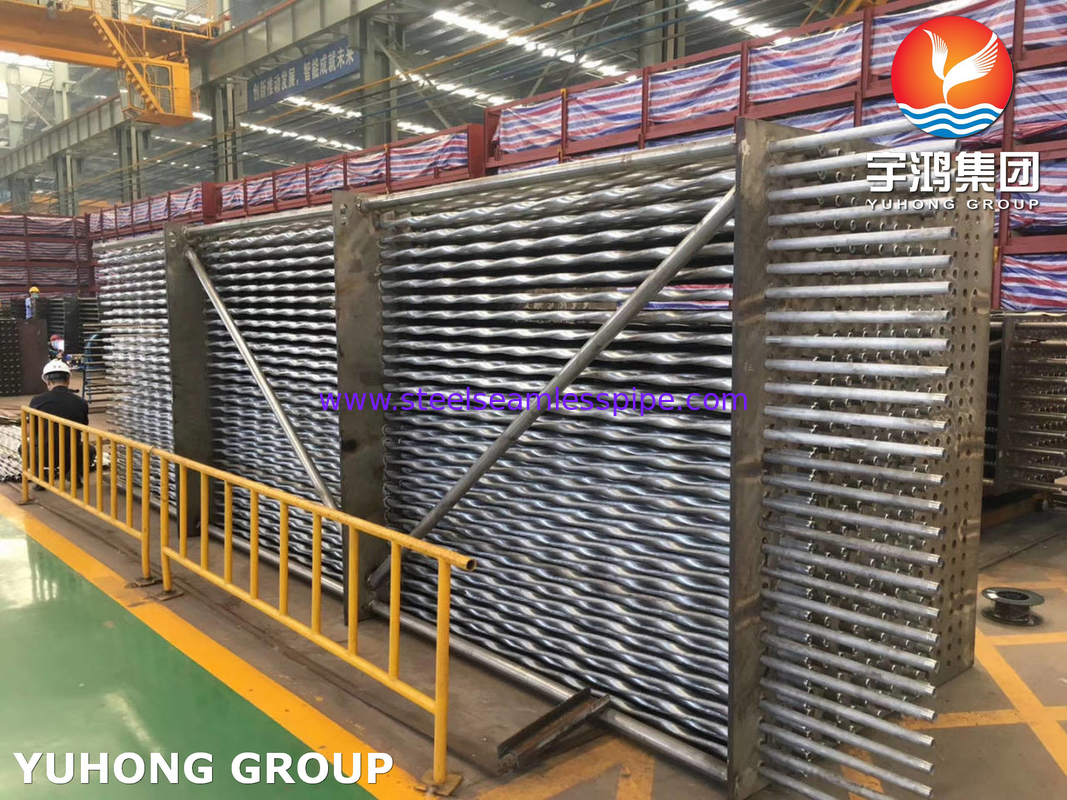

ASTM A312 TP310S Corrugated Stainless Steel Heat Exchanger Tube

What is Corrugated Tube?

A corrugated tube is a flexible, cylindrical conduit characterized by a series of ridges and grooves along its length, providing enhanced durability, thermal expansion absorption, and vibration resistance. These tubes are commonly made from stainless steel, polymers, or specialized alloys to suit various industrial applications. Their unique design allows for excellent bendability without kinking, making them ideal for complex installations. Corrugated tubes are widely used in high-temperature systems (e.g., exhausts, heat exchangers), automotive and aerospace components, chemical processing, and HVAC systems. While they offer superior flexibility and stress resistance compared to smooth tubes, their corrugated structure may require periodic maintenance to prevent debris accumulation. Their versatility makes them essential in demanding engineering environments.

1. Material Composition and Properties:

Grade 310S: An austenitic stainless steel with high chromium (~25%) and nickel (~20%) content, optimized for high-temperature performance. The "S" denotes a low carbon content (≤0.08%), enhancing weldability and reducing carbide precipitation.

Key Properties: Excellent oxidation resistance up to 1100°C (2012°F), good sulfidation resistance, and superior creep strength. Less suitable for chloride-rich environments compared to grades like 316.

2. ASTM A312 Standard Compliance:

Scope: Covers seamless and welded austenitic stainless steel pipes, including dimensional, mechanical, and chemical specifications.

Dimensions: Standard outer diameters, wall thicknesses, and lengths, adjusted for corrugation patterns which enhance flexibility and thermal expansion accommodation.

3. Manufacturing Process:

Base Tube Production: Manufactured as seamless or welded tubes per ASTM A312.

Corrugation: Post-production processes like hydroforming or roll-forming introduce corrugations, increasing surface area and flexibility.

Heat Treatment: Solution annealing post-corrugation to restore corrosion resistance and ductility by dissolving carbides.

4. Mechanical and Performance Specifications:

Mechanical Properties: Typical tensile strength ≥515 MPa, yield strength ≥205 MPa, and elongation ≥35% (post-annealing).

Testing: Hydrostatic testing, non-destructive electric testing (e.g., eddy current), and pressure tests to ensure integrity post-corrugation.

5. Applications:

High-Temperature Environments: Furnaces, heat exchangers, exhaust systems, aerospace, and chemical processing.

Advantages: Corrugations mitigate thermal stress, reduce need for expansion joints, and enhance heat transfer efficiency.

6. Installation and Considerations:

Flexibility: Allows for thermal expansion but requires proper support to prevent sagging.

Maintenance: Corrugations may trap particulates; less ideal for slurry applications without regular cleaning.

7. Comparative Analysis:

Vs. 304/316: Superior high-temperature performance but less corrosion resistance in chloride environments.

Vs. 310H: Lower carbon than 310H improves weldability but reduces high-temperature strength.

8. Standards and Specifications:

Base Tube: ASTM A312 governs material and dimensional specs.

Corrugation: Typically follows manufacturer specifications or additional standards for forming processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!