1. Applications

ASTM B622 C22 (Hastelloy C-22) seamless tubes are used in extreme environments requiring corrosion resistance, high-temperature stability, and mechanical reliability:

Reactors, distillation columns, and piping for sulfuric, hydrochloric, and nitric acid handling.

Heat exchangers in chloride-rich cooling systems (e.g., seawater or brine).

Downhole tubing, subsea umbilicals, and valves in sour gas (H₂S) environments.

Flare stacks and condensers in refineries.

Sterile bioreactors and CIP/SIP (clean-in-place/steam-in-place) systems.

Fuel reprocessing equipment exposed to nitric acid and radioactive waste storage.

Gas turbine combustion liners, geothermal brine pipes, and boiler tubes.

Marine propeller shafts, aerospace hydraulic lines, and semiconductor fabrication tools.

2. Strength

- Mechanical Properties (Per ASTM B622):

Tensile Strength: ≥ 690 MPa (100 ksi)

Yield Strength: ≥ 310 MPa (45 ksi)

Elongation: ≥ 45% (ensures ductility for forming/welding).

Hardness: ≤ 100 HRB (Rockwell B scale).

(1). Corrosion Resistance:

Resists pitting, crevice corrosion, and stress corrosion cracking (SCC) in chlorides, sulfides, and mixed acids (e.g., HCl + FeCl₃).

Performs in both oxidizing (e.g., HNO₃) and reducing (e.g., H₂SO₄) environments.

(2). Temperature Performance:

Retains strength from cryogenic (-196°C) up to 600°C (1112°F).

Resists oxidation and carburization in high-heat settings.

(3). Pressure Integrity:

Seamless construction allows use in high-pressure systems (e.g., hydraulic lines, HPHT oil wells).

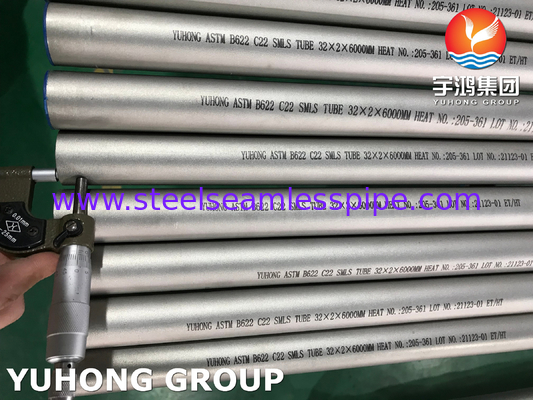

3. Making Process

Raw alloy UNS N06022 (Ni-Cr-Mo-W) is vacuum-melted to ensure purity and homogeneity.

Extrusion: Heated billets are forced through a die to form hollow tubes.

Rotary Piercing: Solid billets are pierced with a mandrel to create seamless tubes.

Cold drawing or rolling improves dimensional accuracy and surface finish.

Solution annealing at 1120–1175°C (2050–2150°F) followed by rapid quenching to dissolve secondary phases and restore corrosion resistance.

Pickling in nitric/hydrofluoric acid to remove oxide layers.

Polishing (optional) for hygienic or high-purity applications.

4. Quality Control:

Non-Destructive Testing (NDT): Eddy current, ultrasonic, or hydrostatic testing to detect flaws.

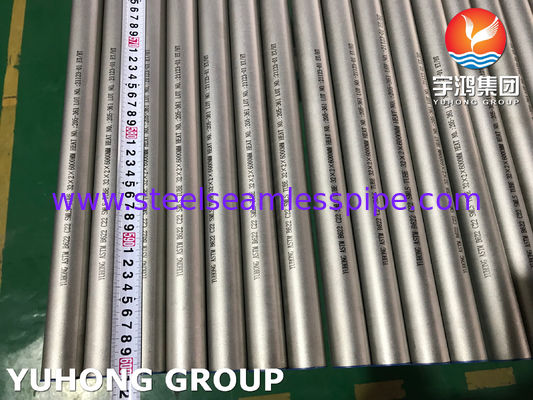

Certification: Mill test reports (MTRs) verify compliance with ASTM B622 for chemistry, mechanical properties, and dimensions.

Key Advantages of Seamless Construction:

No welds = no weak points, ideal for high-pressure/temperature applications.

Uniform grain structure enhances corrosion resistance and fatigue life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!