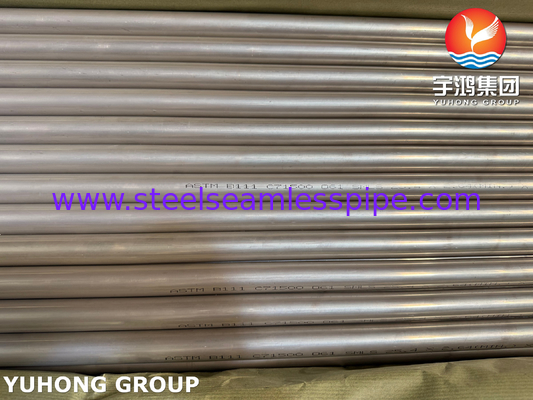

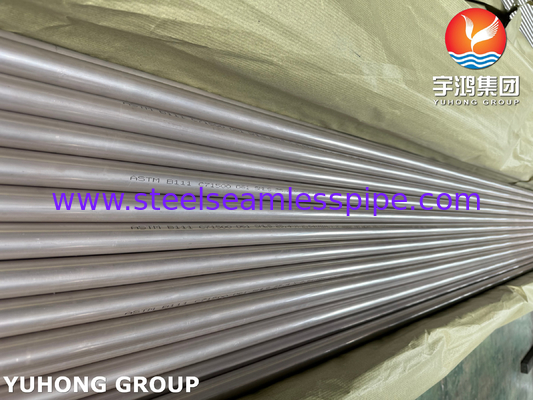

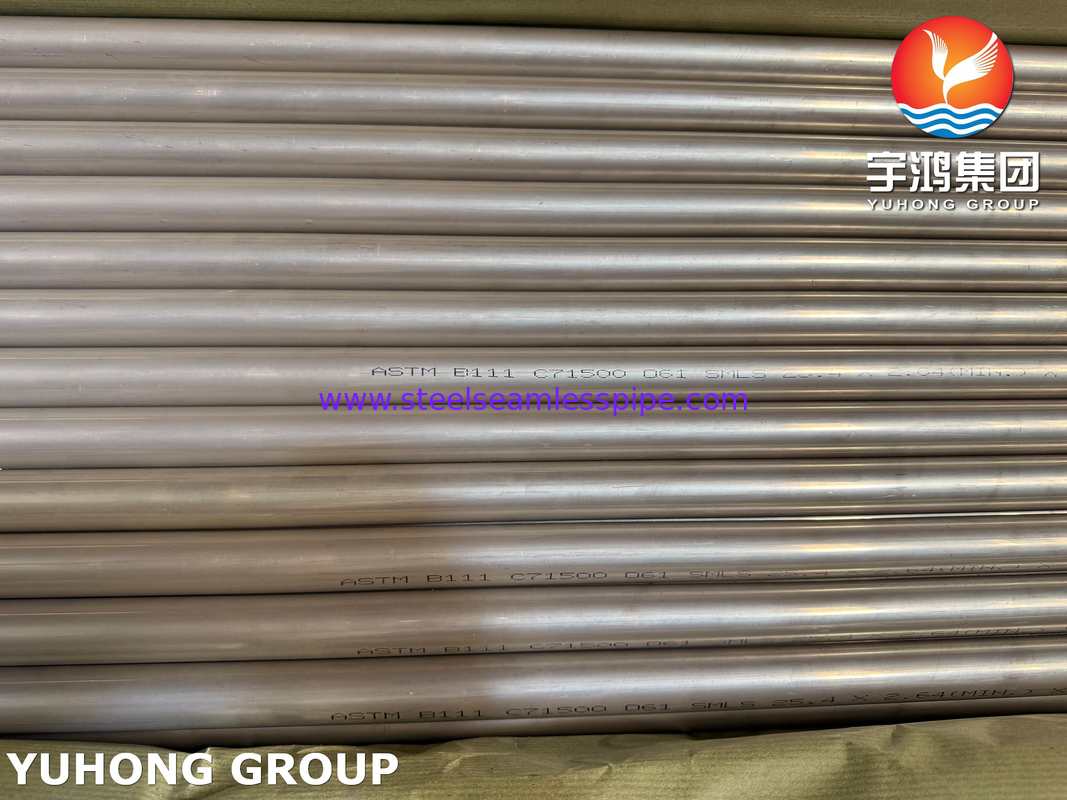

ASME SB111 C71500 Copper Nickel Alloy Seamless Tube for Marine Condenser Application

With 30 years of expertise in industrial tubing and exports to 85 countries, YUHONG specialises in premium C71500 copper-nickel alloy seamless tubes for demanding marine applications. Our production combines 70/30 Cu-Ni alloy with precision cold-drawing technology to deliver tubes with exceptional dimensional accuracy and seamless integrity.

Every tube undergoes rigorous ASME SB111 compliant testing, including hydrostatic pressure examination, eddy current inspection, and full material certification. Trust our decades of experience to provide corrosion-resistant, biofouling-proof solutions for shipbuilding condensers, offshore platforms, and desalination systems worldwide.

Chemical Composition of C71500 Copper-Nickel Alloy

| Element |

Copper (Cu) |

Nickel (Ni) |

Iron (Fe) |

Manganese (Mn) |

Zinc (Zn) |

Lead (Pb) |

| Composition (%) |

Remainder |

29.0–33.0 |

0.50–1.0 |

≤1.0 |

≤1.0 |

≤0.05 |

Mechanical Properties of C71500 Copper-Nickel Alloy

| Temper Designation |

Code |

Name |

Tensile Strength, min (ksi) |

Yield Strength, min (ksi) |

Elongation in 2 in., min (%) |

Applicable Wall Thickness |

| O61 |

O61 |

Annealed |

52 |

18 |

... |

All thicknesses |

| HR50 |

HR50 |

Drawn and Stress-Relieved |

72 |

50 |

12 (≤0.048 in.) / 15 (>0.048 in.) |

≤0.048 in. / >0.048 in. |

Summary of Testing Requirements

| Test Type |

ASTM Standard |

| Chemical Analysis |

B170, E53, E54, E62 |

| Tension Testing |

E8/E8M |

| Grain Size Test |

E112 |

| Expansion Test |

B153 |

| Mercurous Nitrate Test |

B154 |

| Ammonia Vapor Test |

B858 |

| NDT (Eddy Current) |

E243 |

Advantages of ASME SB111 C71500 Copper Nickel Alloy Seamless Tubes for Marine Condenser Applications

1.Superior Corrosion Resistance

With 29-33% nickel content, C71500 alloy offers exceptional resistance to seawater corrosion, pitting, and biofouling, ensuring long-term durability in marine environments.

2. High Mechanical Strength

Annealed (O61): Tensile strength ≥52 ksi, yield strength ≥18 ksi.

Drawn & Stress-Relieved (HR50): Tensile strength ≥72 ksi, yield strength ≥50 ksi—ideal for high-pressure condenser systems.

3.Excellent Ductility

Elongation ≥15% (thicker walls) to 12% (thin walls) post cold-working, enabling complex installations without cracking.

4.T hermal Stability

Maintains structural integrity under fluctuating temperatures, critical for condensers exposed to steam and seawater.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!