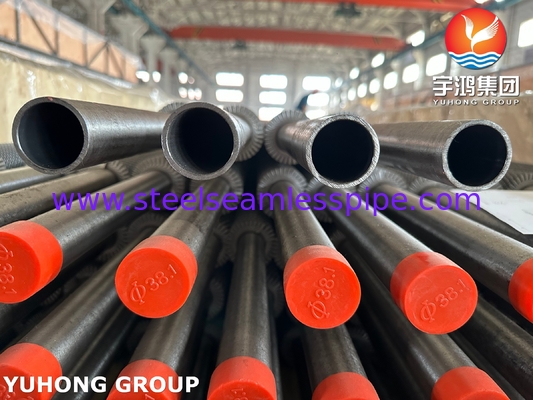

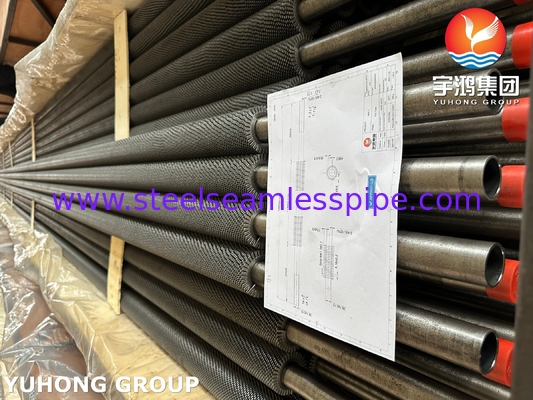

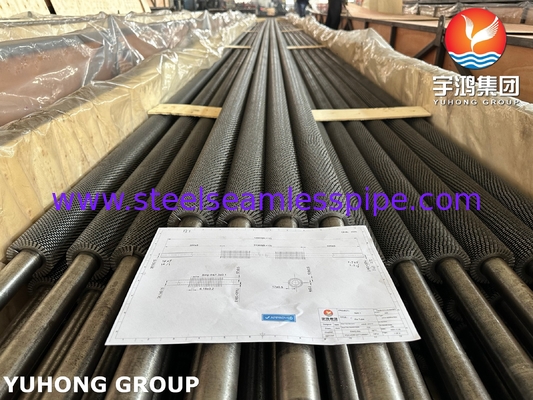

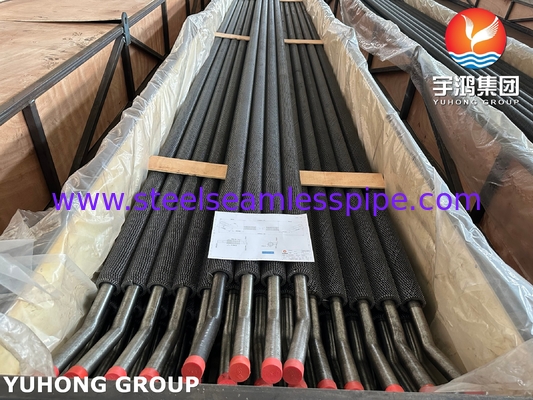

ASTM A213/ ASME SA213 T22 HFW Serrated Fin Tube Two ports can be U Bend For Heat Recovery Steam Generator

SA213 This is an ASTM International specification covering seamless ferritic and austenitic steel boiler, superheater and heat exchanger tubes for high temperature applications.

Good resistance to oxidation and corrosion at high temperatures compared to carbon steel. Good resistance to hydrogen attack and good weldability and formability. Boiler superheater and reheater tubes, heat exchanger tubes in refineries, petrochemical plants and power plants, especially those operating between 500°C and 600°C (930°F - 1110°F).

HFW FIN TUBE , the strip material is welded longitudinally to the base tube by high frequency induction welding or contact resistance welding. The process is fast and economical.

Fin: A continuous strip of metal (usually carbon steel or stainless steel) spirally wound and bonded (extruded, welded or embedded) to the outer surface of the base tube. Fins significantly increase the external heat transfer surface area.

Serrated: The fin strip is slotted or cut at regular intervals along its height. Rather than a solid continuous fin wall, it is a series of small tabs or segments.

Advantages:

Enhanced turbulence: Serrated fins more effectively disrupt the boundary layer of the gas flowing through the fins than regular fins, significantly improving the heat transfer coefficient.

Reduced fouling: The gaps between serrated fins make it more difficult for ash, soot or other particulates to bridge and accumulate severely compared to solid fins.

Reduced weight: Slightly less material than solid fins of equal height.

The toothed finned tube is widely used in heat recovery steam generator (HRSG)

The core reason is that it significantly improves the heat transfer efficiency, anti-ash/corrosion ability and structural reliability, perfectly matching the harsh working conditions of HRSG.

Solve the core problems of HRSG

The flue gas heat transfer efficiency is low. The toothed structure destroys the boundary layer, induces turbulence, and improves the heat transfer coefficient by 30-50%

The flue gas is dusty/easy to accumulate dust. The serrated edge vibrates and self-cleans to reduce ash accumulation and blockage

Frequent start and stop + thermal stress impact High-frequency welding metallurgical bonding, tensile strength ≥ 200 MPa, resistance to thermal fatigue cracking

Heat transfer enhancement: subversive efficiency improvement Turbulence generator: The serrations or cracks (toothed) on the surface of the fins cause the flue gas to produce periodic vortices, breaking the laminar boundary layer (the main source of thermal resistance of the flue gas). The heat transfer coefficient is 30-50% higher than that of smooth fins, and the heat exchange area is reduced by 20% under the same heat exchange rate.

Expanded heating surface: The toothed design increases the effective heat exchange area in a limited space (15-25% more than smooth fins), especially suitable for the compact design of HRSG.

Anti-ash accumulation and self-cleaning: long-term operation guarantee. When the flue gas flows through the serrated edge at high speed, it causes micro-vibration of the fin, preventing the loose ash from adhering

Chemical Composition max %

| Grade |

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Chromium |

Molybdenum |

| T22 / K21590 |

0.05-0.15 |

0.30-0.60 |

0.025 |

0.025 |

0.50 |

1.90-2.60 |

0.87-1.13 |

Mechanical Properties

| Grade |

Tensile Strength,min |

Yield Strength,min |

Elongation (%) |

Hardness, Max |

| T22 / K21590 |

60ksi,415MPa |

30ksi,205MPa |

30 |

163 HB/170 HV |

85 HRB |

Application:

Power Generation Boilers:

Economizers: Use boiler flue gases to preheat feedwater. Serrated fins prevent ash fouling common in coal/biomass combustion processes.

Superheaters and Reheaters: Heat steam to very high temperatures (typically 540-565°C / 1000-1050°F). T22 provides necessary creep strength; serrated fins enhance heat transfer in high-ash flue gases.

Air Preheaters (Ljungström/Regenerative): Recover heat from flue gases to preheat combustion air. Serrated fins excel in this heavily fouling environment.

Heat Recovery Steam Generators (HRSG):

Evaporators, Economizers, Superheaters, Reheaters: Used in combined cycle power plants. T22 handles high pressure/temperature steam. Serrated fins efficiently transfer heat from relatively clean turbine exhaust gases while also effectively preventing potential upstream carryover or pipe fouling.

Refineries and Petrochemical Plants:

Process Heaters and Furnaces (Fired Heaters): Convection Section Tubing (e.g., Crude Heaters, Vacuum Heaters, Coker Heaters, Reformer Feed Heaters). T22 resists high temperature sulfidation corrosion. Serrated fins improve heat transfer efficiency and prevent fouling from coke, catalyst fines, or soot.

Waste Heat Boilers (WHB):

Recover heat from process streams (e.g., FCC flue gas, reformer flue gas). T22 handles steam generation; serrated fins are suitable for particulate or coking gases.

Hydrogen Plant Reformers:

Convection Section Tubing exposed to high temperature flue gases.

Chemical Processing:

High Temperature Process Gas Coolers/Heaters: Chromium-Molybdenum steels are required when the gas stream contains particulates, condensables, or is prone to fouling, and when the temperature is high.

Air Heaters (Regenerative):

Industrial systems use waste heat from furnaces or kilns to preheat combustion air, especially when the flue gas is dirty.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!