- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

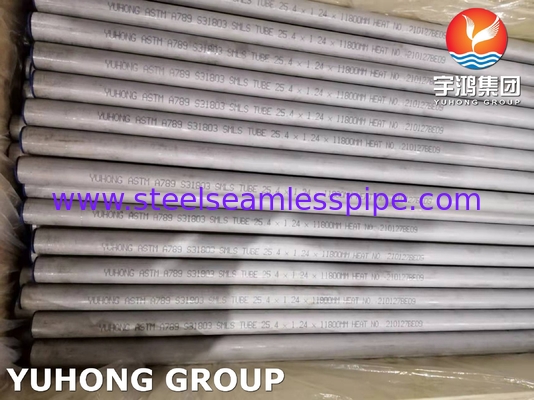

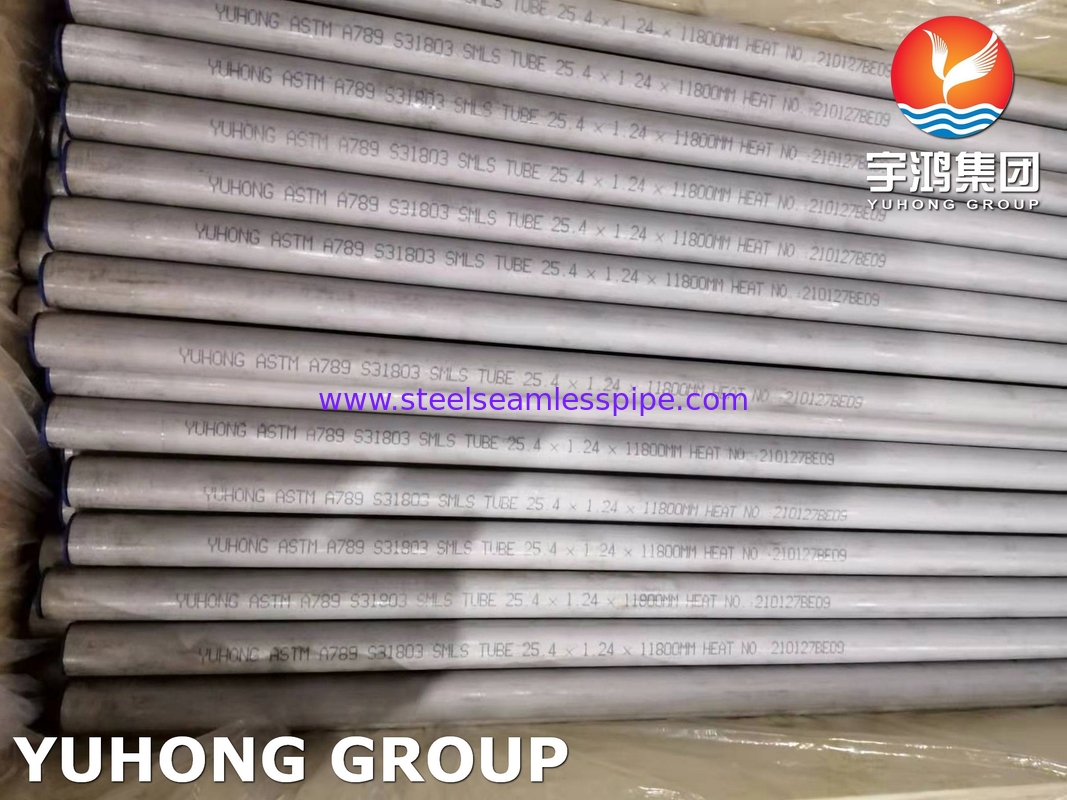

ASTM A789 UNS S31803 1.4462 Seamless and Welded Duplex Stainless Steel Tube

ASTM A789 UNS S31803 (1.4462) Seamless and Welded Duplex Stainless Steel Tube is a high-performance corrosion-resistant steel tube designed for demanding industrial applications. It is manufactured from duplex stainless steel (austenitic-ferritic structure), offering excellent strength, pitting resistance, and stress corrosion cracking resistance. This product is available in both seamless and welded forms, with a controlled averange/ minimum wall thickness to ensure structural integrity under high-pressure and harsh environments. It is widely used in oil & gas, chemical processing, desalination, and marine engineering.

1.Chemical & Mechanical Properties

| ASTM A789 UNS S31803 Chemical Composition (%) |

| C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N |

| ≤ 0.030% |

≤ 2.00% |

≤ 0.030% |

≤ 0.020% |

≤ 1.00% |

21.0 - 23.0% |

4.5 - 6.5% |

2.5 - 3.5% |

0.08 - 0.20% |

Mechanical Properties

| Property |

Standard Value |

| Tensile Strength |

620 - 795 MPa |

| Yield Strength (0.2% offset) |

≥ 450 MPa |

| Elongation |

≥ 25% |

| Hardness (Brinell) |

≤ 32 HRC |

| (-46°C) Charpy V-notch (-46°C) |

≥40 J |

Key Mechanical Characteristics

- High Strength Characteristics

- Excellent Toughness

- Excellent Fatigue Performance

- Physical Properties

2. Key Adventages

- Superior Strength-to-Weight Ratio

High strength properties: Yield strength (≥450MPa) is twice that of 304 stainless steel, with tensile strength (620-795MPa) significantly exceeding conventional austenitic grades.

Weight reduction: Allows 20-30% material savings compared to standard stainless steels at equivalent pressure ratings.

-

Outstanding Corrosion Resistance

Dual protection: Synergistic effect of Cr(21-23%)+Mo(2.5-3.5%)+N(0.08-0.20%)

Specialized resistance: Chloride stress corrosion cracking, pitting/crevice corrosion (PREN≥35), acid media

Lower lifecycle cost: 40-60% savings vs nickel alloys, 2-3x service life vs 316L

Easy installation: Excellent weldability (no PWHT required), CTE similar to carbon steel (13.5×10⁻⁶/℃)

Wide temperature range: Stable performance from -50℃ to 300℃

Dual-phase benefits: Ferrite phase for strength + Austenite phase for toughness

3. Key Applications

- Oil & Gas: Subsea pipelines, X-mas tree components, LNG heat exchangers

- Chemical: Reactors, crystallizers, pickling equipment

- Desalination: High-pressure RO vessels, brine heaters

- New Energy: Geothermal casings, hydrogen storage

Selection Guidance

- High-strength+corrosion resistance combo

- Chloride-containing media

- Weight-sensitive high-pressure systems

—————————————————————————————————————————————————————————————————————————

Order information:

Orders for product under this specification should include as following, so that we can provide you with a more accurate price.

- Quantity (inch, metres, or number of lengths)

- Type of product (seamless or welded tubes)

- Grade

- Size (outside diameter and average wall thickness, unless minimum wall thickness is specified)

- Length (specific or random)

- Special requirements

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!