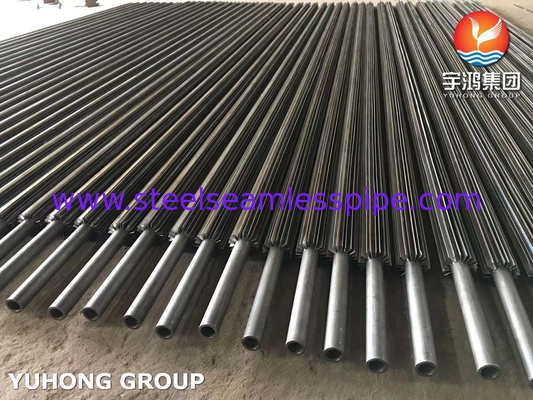

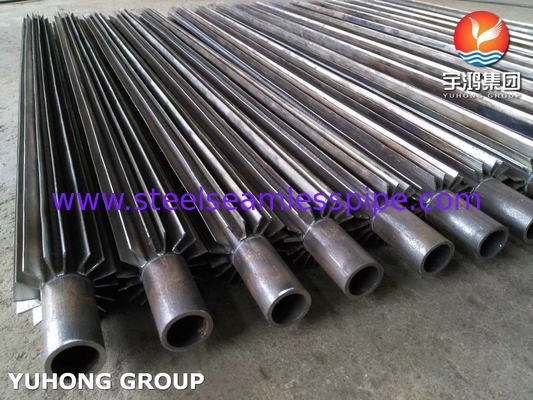

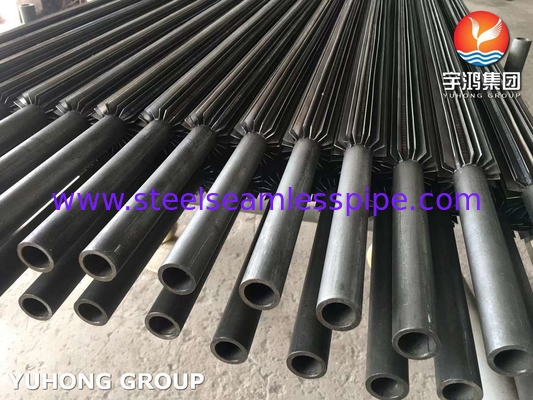

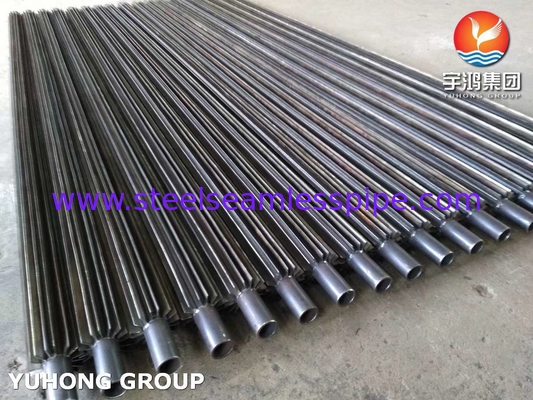

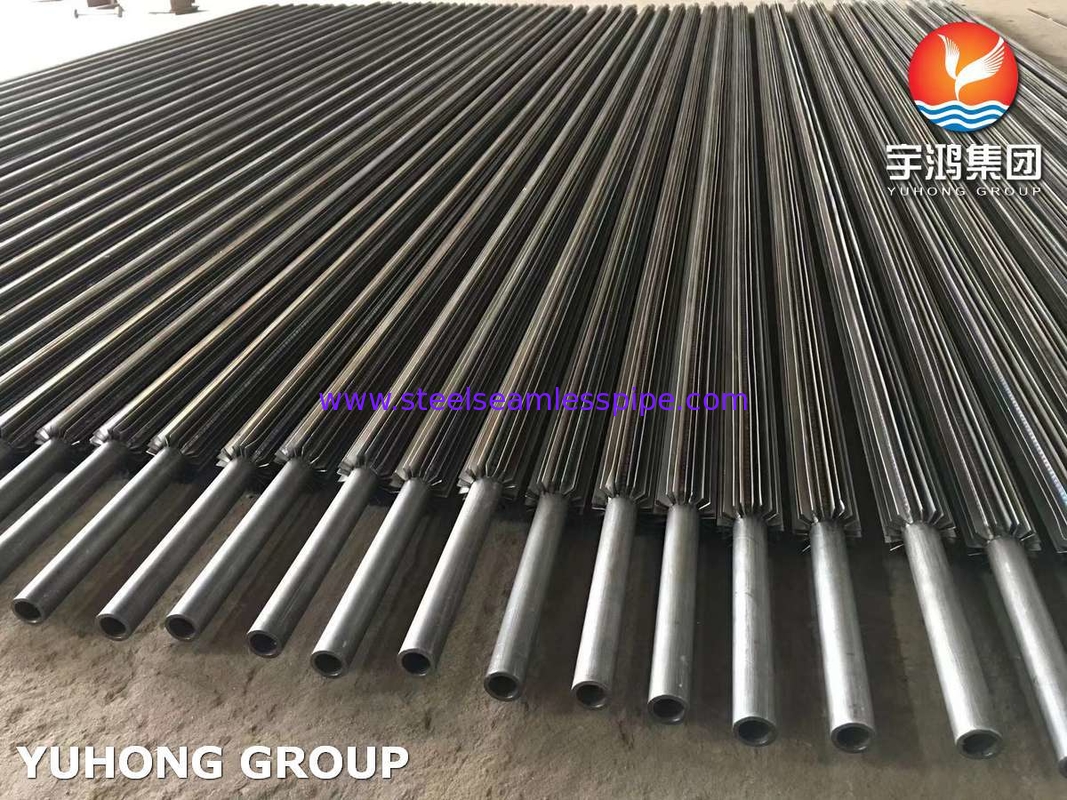

ASTM SA210 Gr A1 Longitudinal Fin Tube With Carbon Steel Fin

Longitudinal finned tube is a kind of high-efficiency heat transfer element, which is made by closely welding or integrally forming metal thin fins along the axial direction on the outer surface of metal base tube (such as steel, copper, aluminum). Its core value lies in expanding the heat transfer area outside the tube by several times to dozens of times (the fin ratio can reach 5~20 times).

This structural design specifically solves the efficiency bottleneck problem of heat exchange between gas (such as air, flue gas) and fluid in the tube (water, steam, refrigerant, etc.). Due to the extremely low heat transfer coefficient on the gas side, it often becomes the dominant factor in the thermal resistance of the system; the fin penetrates the gas boundary layer deeply by extending the heat transfer surface, and uses the disturbance effect of the fin edge on the airflow to significantly reduce the thermal resistance on the gas side, so that the overall heat transfer efficiency can be increased by 2~10 times compared with the bare tube.

Reliable manufacturing is the key to achieving its performance, which mainly relies on processes such as high-frequency resistance welding, integral extrusion (such as aluminum tube) or brazing. These processes ensure that the connection interface between the fin and the base tube has high thermal conductivity (reducing contact thermal resistance) and sufficient mechanical strength to withstand thermal stress and vibration under working conditions.

When designing longitudinal finned tubes, it is necessary to finely optimize the fin parameters (height, thickness, spacing) to strike a balance between maximizing heat transfer performance and controlling gas flow resistance (pressure drop). At the same time, it is necessary to take into account both material selection and special working conditions, such as selecting corrosion-resistant materials (such as ND steel or coating) in environments prone to dew point corrosion such as sulfur-containing flue gas, considering anti-ashing resistance in dusty gases (such as using larger fin spacing), and ensuring structural reliability under vibration conditions.

Based on its excellent gas-side heat transfer enhancement and compactness, longitudinal finned tubes are widely used in various scenarios dominated by gas-liquid heat exchange and with high space or efficiency requirements. Typical applications include: waste heat recovery equipment (economizer, air preheater) in boiler systems, process gas coolers/heaters in the petrochemical industry, evaporators/condensers in refrigeration systems, and hot air heaters in industrial drying equipment. It is a key technology to achieve compact equipment and efficient energy utilization.

Relationship between fin direction and airflow

| TYPE |

Fin direction |

Airflow direction |

Convection mechanism |

| Longitudinal Fin Tubes |

Fins are parallel to the tube axis |

Gas flows parallel to the fins |

Airflow flows along the length of the fins, with weak disturbance |

| Horizontal fin tube |

Fins are perpendicular to the tube axis (spiral/annular) |

Gas flows perpendicular to the fins |

Airflow is forced to rotate/disturbed by the fins, causing strong disturbance |

Heat transfer performance and resistance comparison

| Characteristics |

Longitudinal fin tube |

Horizontal fin tube |

| Heat transfer coefficient |

Medium (weak air flow disturbance) |

Higher (swirl destroys boundary layer) |

| Heat transfer area |

Fin ratio 5~20 times |

Fin ratio 10~30 times (can be higher) |

| Air flow resistance |

Lower (straight flow channel) |

Significantly higher (swirl energy consumption) |

| Anti-dust accumulation |

Excellent (straight channel is not easy to be blocked by dust) |

Poor (spiral groove is easy to be blocked by dust) |

Application

Energy and power

Boiler economizer, air preheater, gas turbine waste heat boiler

Petrochemical

Process gas heater/cooler, reaction product condenser, lubricating oil coolin

HVAC & refrigeration

Evaporative condenser, air cooler coil, heat pump outdoor unit

Industrial waste heat recovery

Drying equipment, ceramic kiln, glass melting furnace flue gas waste heat utilization

Transportation machinery

Diesel engine intercooler, hydraulic oil radiator

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!