What is ASTM A335 P9 soild fin tube?

Base pipe material: ASTM A335 P9:

ASTM A335 P9 is a chromium-molybdenum alloy steel grade known for its high temperature strength and oxidation resistance.

It is widely used in power generation, petrochemical, and refinery applications where elevated temperature service is required.

This material offers good resistance to sulfur corrosion and structural stability under high thermal stress.

What is fin tube?

P9 alloy demonstrates excellent weldability and formability, making it suitable for fabricating heat exchanger components.

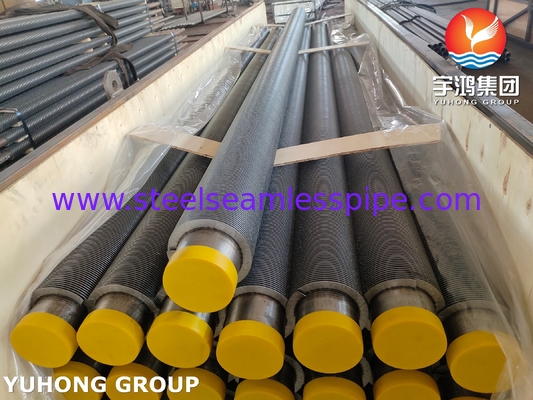

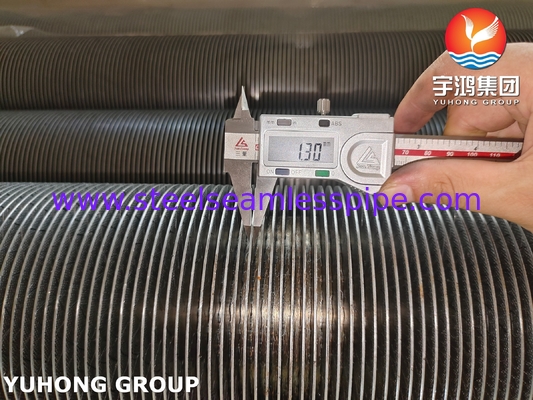

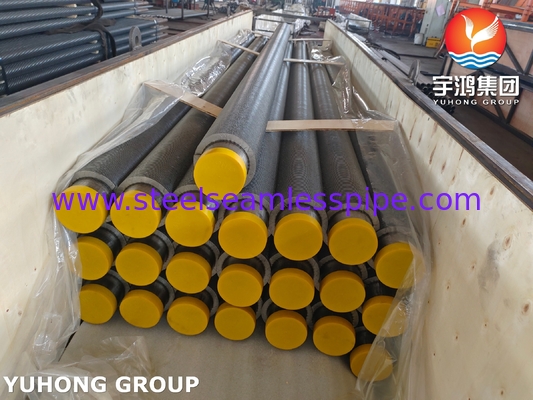

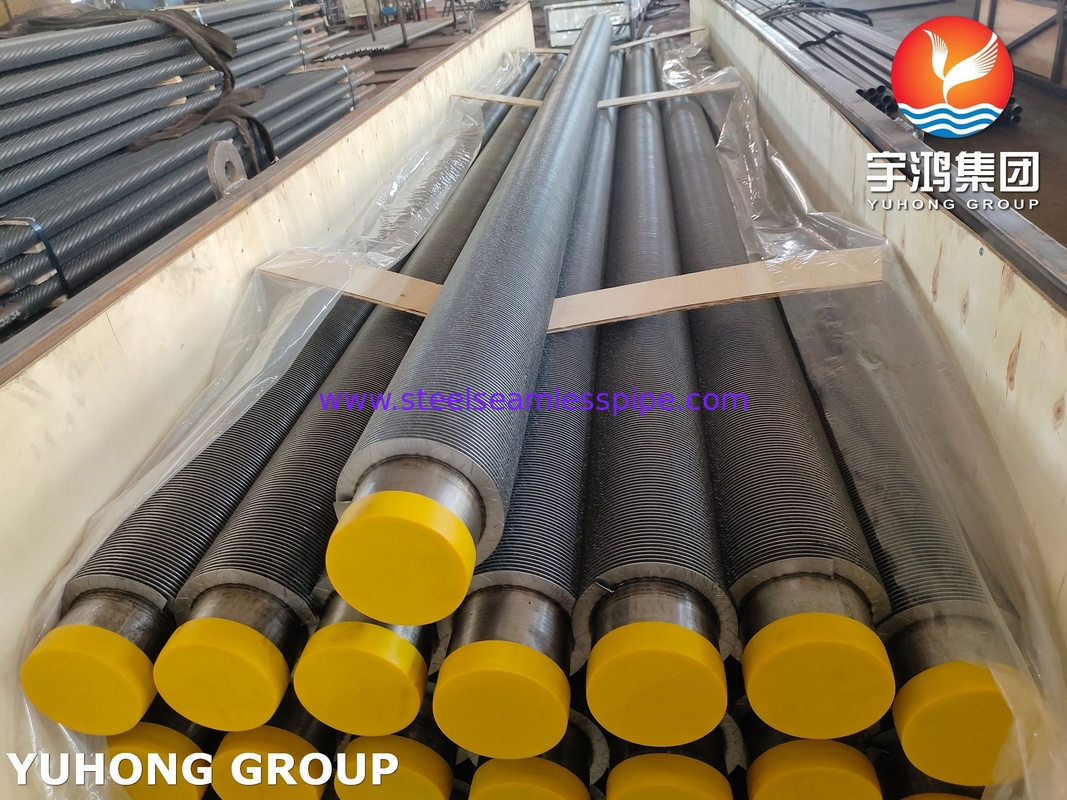

Solid fin tubes are integral finned tubes where the fins are formed directly from the tube material or attached firmly through a robust process such as extrusion or welding. They are designed for efficient heat transfer in demanding environments, including high-temperature and high-pressure conditions commonly found in boilers, heaters, and process gas coolers.

Fin Tube Types and Material Specifications:

Size Reference for Different Types of Fin Tubes

| Type | Description | Base tube | Fin specification (mm) |

| O.D. (mm) | Fin pitch | Fin height | Fin thick |

| Embedded | G-type fin tueb | 16-63 | 2.1-5 | <17 | ~0.4 |

| Extruded | Single metal combined metal | 8-51 | 1.6-10 | <17 | 0.2-0.4 |

| Low fin tube t-type fin tube | 10-38 | 0.6-2 | <1.6 | ~0.3 |

| Bamboo tube corrugated tube | 16-51 | 8-30 | <2.5 | / |

| Wound | l/kl/ll type fin tube | 16-63 | 2.1-5 | <17 | ~0.4 |

| String | String fin tube | 25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-type | U-type tube | 16-38 | / | / | / |

| Welding | HF-welding fin tube | 16-219 | 3-25 | 5-30 | 0.8-3 |

| H/HH type fin tube | 25-63 | 8-30 | <200 | 1.5-3.5 |

| Studed fin tube | 25-219 | 8-30 | 5-35 | φ5-20 |

Chemical Composition(%)

| P9 Chemical Composition(%) |

| Element | C | Si | Cr | Mn | P | Mo | S |

| Range | ≤0.15 | 0.50-1.00 | 8.00-10.00 | 0.30-0.60 | ≤ 0.025 | 0.9-1.10 | ≤0.025 |

Mechanical Properties

| ASTM A335 P9 Mechanical Properties |

| Tensile Strength | Yield Strength | Hardness | Elongation |

| 415MPa | ≥205MPa | ≤ 179HB | 30% |

Equivalent Material of P9

| UNS | BS | ISO | ASTM | ASME | JIS G 3468 | DIN | NK | ABS |

| K81590 | 3604-620 | 9329-2 P9 | A335 P9 | SA335 P9 | STPA 26 | 17175 12CrMo195 | KSTPA 26 | ABS Gr.9Cr |

Applications of ASTM A335 P9 HFW Solid Fin Tube

1.Heat recovery systems in refineries and chemical plants

2.Boiler and superheater elements in thermal power stations

3.Process gas heaters and coolers

4.Air preheaters and economizers

5.High-temperature finned tube exchangers in sulfur recovery units

Competitive Advantages

1.High-quality seamless base tube ensuring reliability under pressure

2.Fins are integrally made or welded with full penetration for superior thermal contact and mechanical strength

3.Capable of operating in temperatures up to 600°C

4.Custom engineering support to optimize performance for specific applications

5.Full compliance with ASME, ASTM, and customer-specific standards

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!