What is ASME A376 TP347H HFW Solid Fin Tube with CS Fin?

Base pipe material: ASTM SA376 TP347H:

ASTM SA376 TP347H is a stabilized austenitic stainless steel grade, renowned for its exceptional high-temperature strength and superior resistance to intergranular corrosion. The addition of niobium (stabilizing element) effectively prevents carbide precipitation during exposure to elevated temperatures.

It is extensively employed in applications involving severe corrosive environments and high-temperature service, such as in superheaters, heat exchangers, and pressure vessels within power boilers and petrochemical industries. This material maintains excellent mechanical properties and oxidation resistance under sustained thermal cycling.

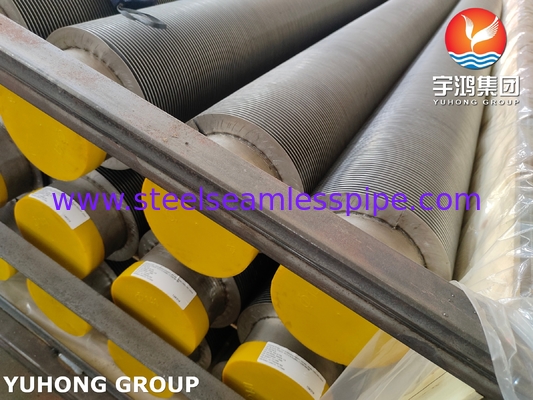

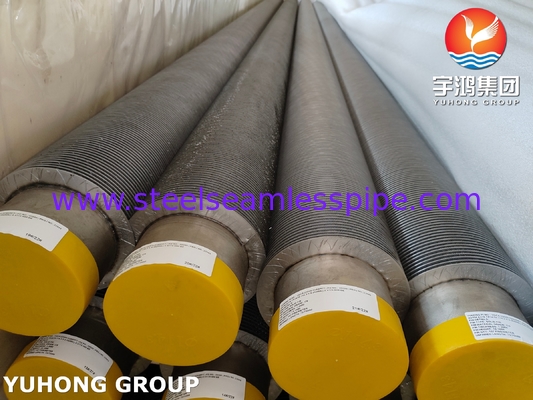

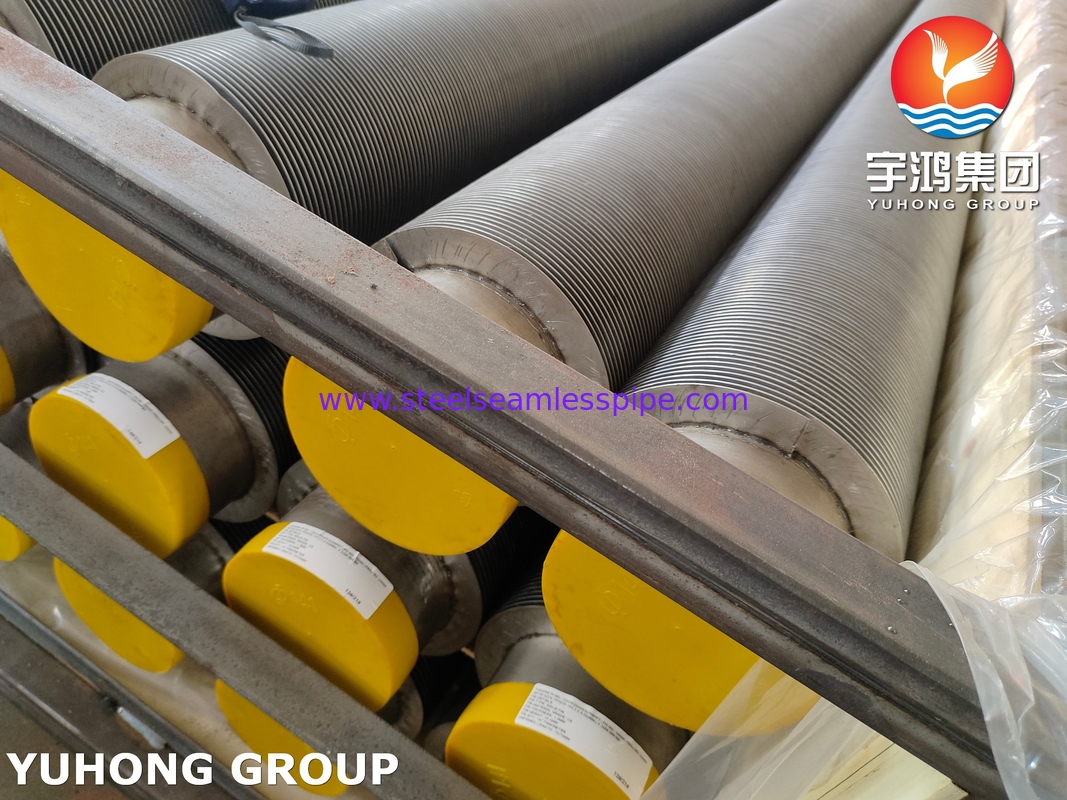

What is HFW Solid Fin Tube ?

The HFW Solid Fin Tube is a high-efficiency heat exchanger component made via high-frequency welding. It involves helically wrapping a metal strip around the base tube and fixing it via welding using high-frequency current, with no fusion welding and secure bonding. Featuring solid helical fins (increasing heat transfer area) and flexible material options (corrosion-resistant or high-temperature-resistant), it boasts high thermal efficiency, durability, and some variants can withstand up to 800°C. Applied in power generation, petrochemicals, HVAC, etc., it is manufactured in compliance with international standards like ASTM, serving as a preferred component for optimizing heat exchange in industry.

Fin Tube Types and Material Specifications:

Size Reference for Different Types of Fin Tubes

| Type |

Description |

Base tube |

Fin specification (mm) |

| O.D. (mm) |

Fin pitch |

Fin height |

Fin thick |

| Embedded |

G-type fin tueb |

16-63 |

2.1-5 |

<17 |

~0.4 |

| Extruded |

Single metal combined metal |

8-51 |

1.6-10 |

<17 |

0.2-0.4 |

| Low fin tube t-type fin tube |

10-38 |

0.6-2 |

<1.6 |

~0.3 |

| Bamboo tube corrugated tube |

16-51 |

8-30 |

<2.5 |

/ |

| Wound |

l/kl/ll type fin tube |

16-63 |

2.1-5 |

<17 |

~0.4 |

| String |

String fin tube |

25-38 |

2.1-3.5 |

<20 |

0.2-0.5 |

| U-type |

U-type tube |

16-38 |

/ |

/ |

/ |

| Welding |

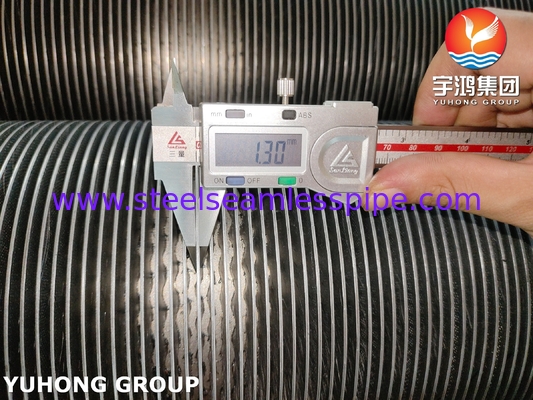

HF-welding fin tube |

16-219 |

3-25 |

5-30 |

0.8-3 |

| H/HH type fin tube |

25-63 |

8-30 |

<200 |

1.5-3.5 |

| Studed fin tube |

25-219 |

8-30 |

5-35 |

φ5-20 |

Chemical Composition(%)

|

A376 TP347H Chemical Composition(%)

|

| Element |

C |

Si |

Cr |

Mn |

P |

Ni |

S |

| Range |

0.04-0.10 |

≤0.75 |

17.00-20.00 |

≤2.00 |

≤ 0.030 |

9.00-13.00 |

≤0.030 |

Mechanical Properties

| A376 TP347H Mechanical Properties |

| Tensile Strength |

Yield Strength |

Hardness |

Elongation |

| 515MPa |

≥205MPa |

≤ 192HB |

≥35% |

Equivalent Material of TP347H

| UNS |

JIS G |

ISO |

ASTM |

ASME |

BS |

DIN |

| S34709 |

SUS 347H |

1.4550 |

A376 TP347H |

SA376 TP347H |

304S12 |

17175 12CrMo195 |

Applications of ASME A376 TP347H HFW Solid Fin Tube with CS Fin

1. Superheaters and reheaters in advanced power generation boilers

2. Process gas coolers and heat exchangers in fertilizer and chemical processing plants

3. Air preheaters and economizers in waste heat recovery systems

4. Finned tube bundles in catalytic reforming and hydroprocessing units

5. Heat recovery steam generators (HRSGs) in gas turbine combined cycle plants

Competitive Advantages

1. Excellent temp & corrosion resistance: TP347H stainless steel endures over 650℃, resists intergranular corrosion, fitting high-temp scenarios like boilers and heat exchangers.

2. High heat-transfer cost-efficiency: CS fins boost heat-transfer area for better efficiency, with lower cost than full-stainless fins, balancing performance and cost.

3. Reliable & durable HFW process: High-Frequency Welding ensures tight tube-fin bonding, offering high strength, low leakage risk, and longer service life.

4. Wide application adaptability: Meets both corrosion resistance and heat-transfer needs, suits power/chemical industries, and cuts long-term maintenance costs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!