ASTM A790 S32750 Chemical Composition

| UNS Designation |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

N |

Cu |

Other |

| S32750 |

0.03 |

1.20 |

0.035 |

0.02 |

0.80 |

6.0-8.0 |

24.0–26.0 |

3.0–5.0 |

0.24–0.32 |

0.5 |

... |

ASTM A790 S32750 Seamless Tube Features

High Strength: Combines the properties of austenitic and ferritic stainless steels.

Corrosion Resistance: Excellent resistance to pitting and crevice corrosion in chloride environments.

Good Weldability: Suitable for various welding processes.

Low Thermal Expansion: Offers stability under temperature fluctuations.

ASTM A790 S32750 Seamless Tube Application

Oil and Gas: Used in pipelines, heat exchangers, and pressure vessels.

Chemical Processing: Ideal for environments with high chloride concentrations.

Marine Applications: Suitable for offshore structures and marine equipment.

Power Generation: Used in nuclear and fossil fuel power plants.

ASTM A790 S32750 Seamless Tube Advantages

Cost-Effective: Offers a balance of performance and cost compared to super duplex steels.

Durability: Long service life due to high resistance to corrosion and stress corrosion cracking.

Versatility: Applicable in various industries due to its mechanical and corrosion-resistant properties.

ASTM A790 S32750 Seamless Tube Services

Custom Fabrication: Tailored sizes and shapes available based on project requirements.

Heat Treatment: Options for stress relieving and normalization to enhance material properties.

Surface Finishing: Various finishes available, including pickling and passivation.

ASTM A790 S32750 Seamless Tube FAQs

Q1: What is the difference between duplex and super duplex stainless steel?

A1: Super duplex has a higher alloy content, providing enhanced resistance to corrosion and higher strength, but it is also more expensive.

Q2: Can S32750 be welded?

A2: Yes, S32750 can be welded using standard methods, although care must be taken to avoid overheating.

Q3: What is the maximum operating temperature for S32750?

A3: Typically, it can withstand temperatures up to around 300°C (572°F), but this can vary based on specific conditions.

Q4: Is S32750 suitable for cryogenic applications?

A4: Yes, it maintains good toughness at low temperatures, making it suitable for cryogenic applications.

Q5: How should S32750 tubes be cleaned?

A5: Use mechanical or chemical cleaning methods, ensuring that no chlorides remain on the surface to prevent corrosion.

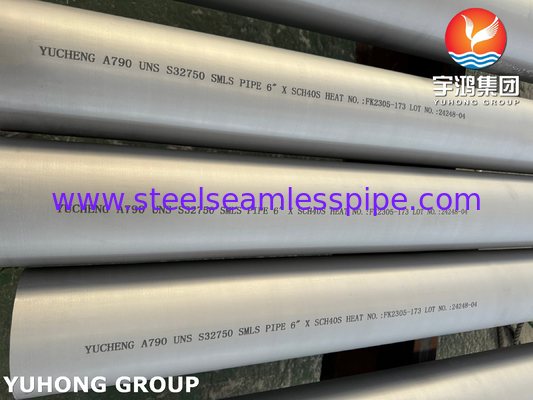

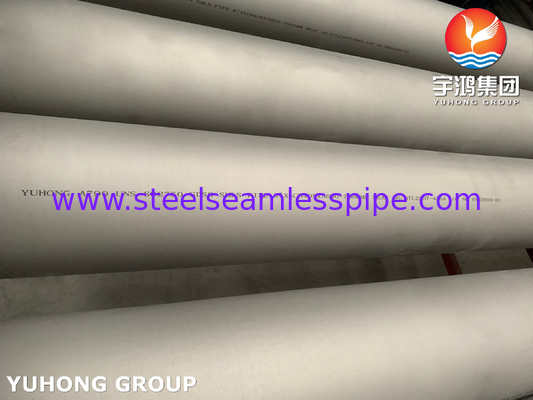

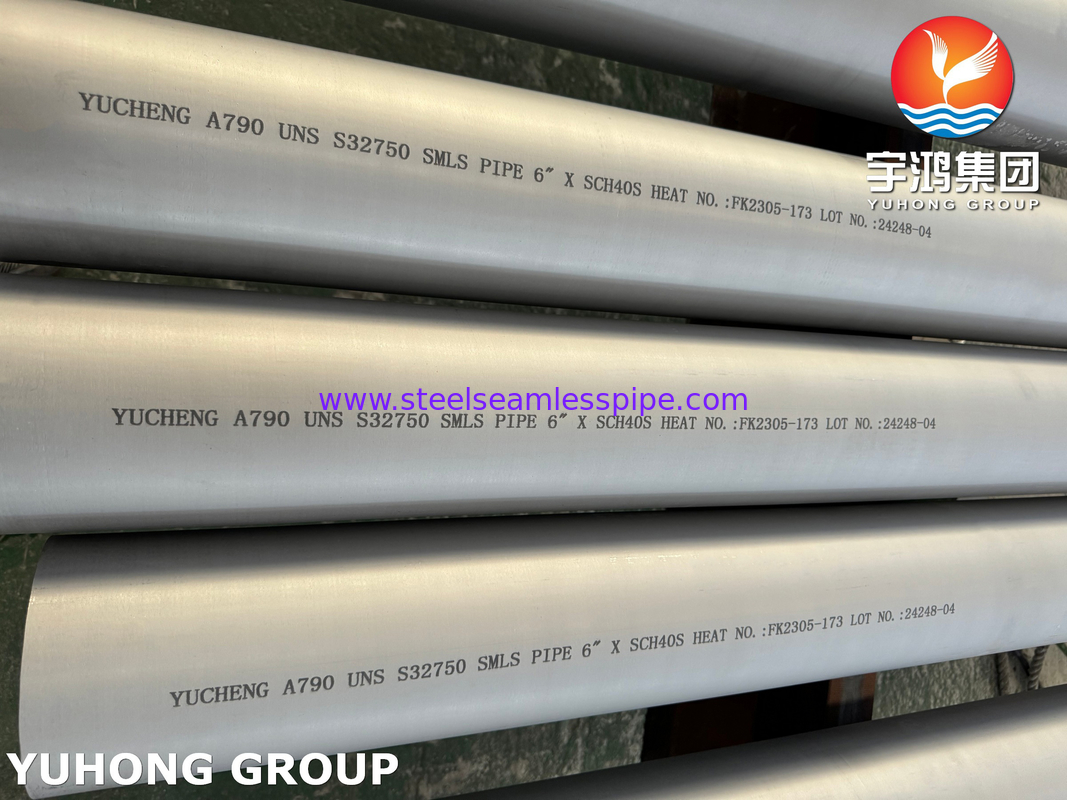

ASTM A790 S32750 Duplex Stainless Steel Tube For Pipelines and Power Plant

We are the manufacturer of duplex stainless steel seamless pipe with our own factory. And we can produce the S32202, S32205, S32750, S32760, S31500...pipe. ASTM A790 S32750 duplex stainless steel seamless pipes are a robust choice for various demanding applications due to their unique combination of strength, corrosion resistance, and weldability. Their duplex structure provides advantages in both mechanical properties and resistance to harsh environments, making them suitable for industries such as oil and gas, chemical processing, and marine applications. With options for custom fabrication, heat treatment, and surface finishing, these tubes offer versatility and durability, ensuring long service life and cost-effectiveness.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!