- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

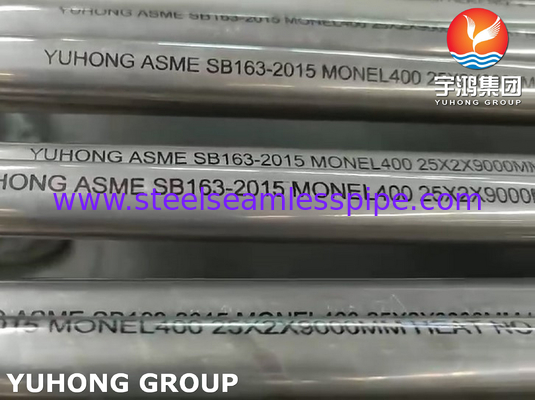

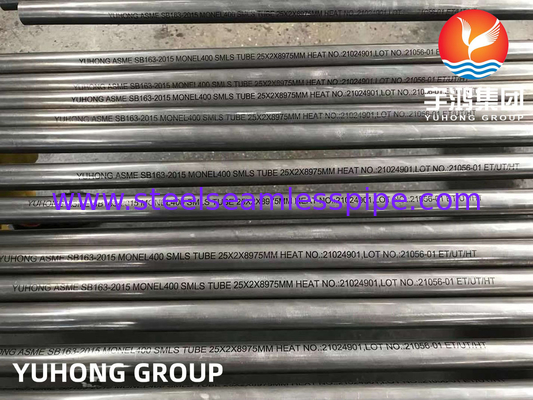

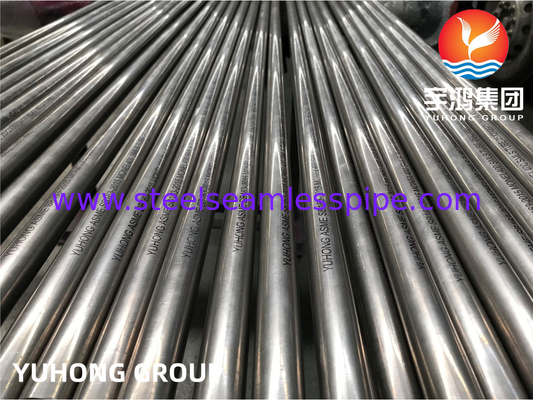

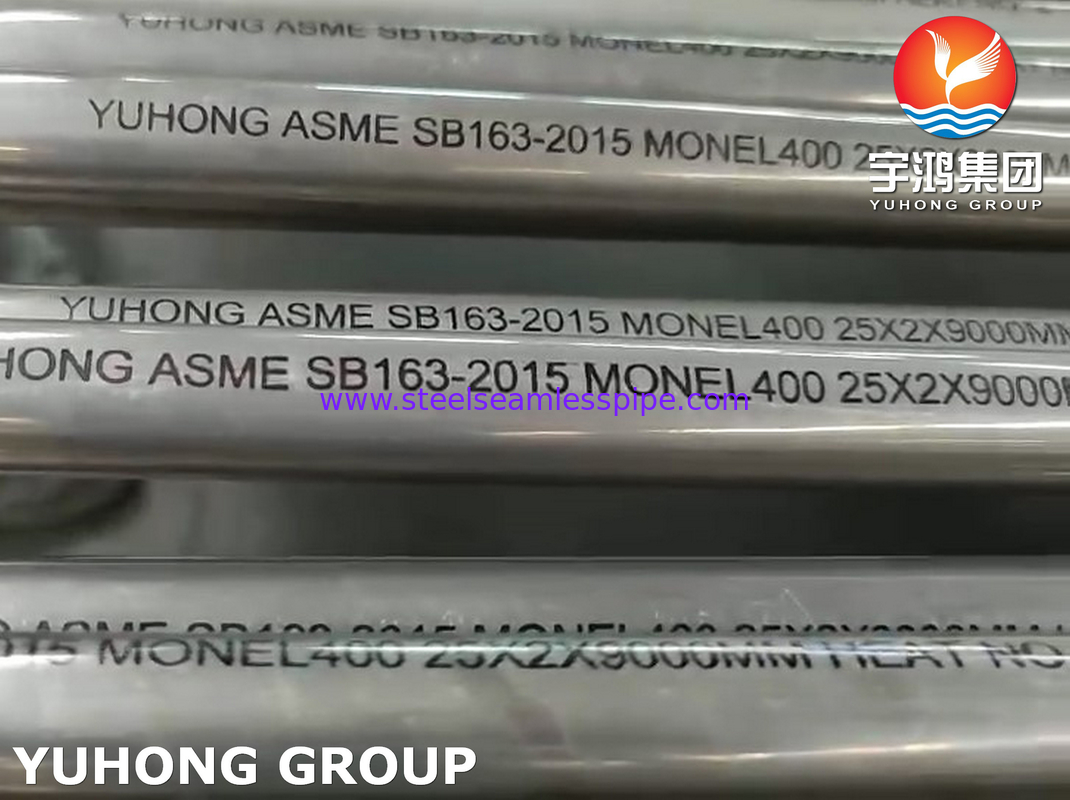

ASME SB163 MONEL 400 (UNS N04400) Nickel Alloy Seamless Tube for Heat Exchanger and Condenser

The ASME SB163 MONEL 400 (UNS N04400) is a premium nickel-copper alloy seamless tube specifically engineered for critical heat transfer applications in highly corrosive environments. Manufactured to strict ASME boiler and pressure vessel code standards, this alloy combines 67% nickel and 30% copper to deliver exceptional resistance to seawater, acids (including hydrofluoric and sulfuric), alkalis, and high-temperature steam. Its unique metallurgical structure provides immunity to chloride-ion stress corrosion cracking while offering superior thermal conductivity (21.8 W/m·K) for efficient heat exchange. The product is extensively used in shell-and-tube heat exchangers, condensers, and other pressure vessels where reliability in aggressive media is paramount, particularly in chemical processing, offshore oil & gas, marine engineering, and power generation applications.

Equivalent Grades

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR

|

EN |

| Monel 400 |

2.436 |

N04400 |

NW 4400 |

NA 13 |

МНЖМц 28-2,5-1,5 |

NU-30M |

NiCu30Fe |

1.Chemical & Mechanical Properties

| ASME SB163 MONEL 400 Chemical Composition (%) |

|

C

|

Mn

|

Si

|

S

|

Cu

|

Fe

|

Ni

|

| ≤0.30% |

≤2.00% |

≤0.50% |

≤0.24% |

28.0%-34.0% |

≤2.50% |

≥63.00% |

Mechanical Properties

| Property |

Standard Value |

| Tensile Strength |

550 MPa (80 ksi) |

| Yield Strength (0.2% offset) |

240 MPa (35 ksi) |

| Elongation |

40% in 50mm |

| Hardness (Brinell) |

65-90HRB |

| Heat treatment |

1350℃ (2460℉)

|

2. Key Adventages

-

Superior Corrosion Resistance

Excellent seawater resistance - Ideal for desalination, marine and offshore applications

Resists acids/alkalis - Performs well in sulfuric acid, hydrofluoric acid and alkaline environments

-

Outstanding Mechanical Properties

Wide temperature range: Maintains properties from -196°C to 480°C

High strength & ductility: Tensile strength ≥480MPa, elongation ≥35%

Multi-standard certified: Complies with ASME SB163, ASTM B163/B165, etc.

Rigorous QC: Includes EN 10204 3.1/3.2 material certificates

-

Application-Oriented Design

High thermal conductivity (21.8 W/m·K) for efficient heat transfer

Custom solutions: U-bending, special sizes & surface finishes available

-

Long-Term Cost Efficiency

Extended service life: Corrosion resistance reduces replacement needs

Low maintenance: Resists biofouling, minimizing cleaning costs

3. Key Applications

Offshore platform heat exchange systems: Seawater coolers, crude oil heaters

Gas processing equipment: Amine exchangers, sour gas condensers

Subsea pipeline systems: Heat transfer components for subsea equipment

-

Chemical & Petrochemical Industry

Strong acid media exchangers: Sulfuric/HF acid production equipment

Chlor-alkali industry: Electrolyzer heat transfer parts

Polymer production: High-temperature monomer condensation systems

Nuclear plants: Steam generator U-tubes, spent fuel cooling systems

Thermal power plants: FGD system heat transfer components

Geothermal power: High-salinity geothermal fluid handling equipment

-

Desalination & Marine Engineering

MED plants: Evaporator tube bundles, brine heaters

RO systems: High-pressure seawater pre-treatment exchangers

Marine systems: Engine coolers, ballast water treatment units

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!