- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

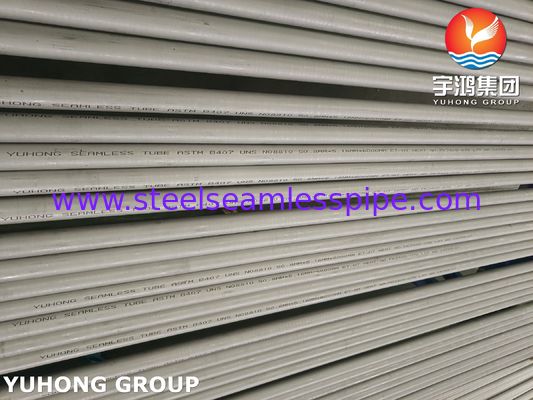

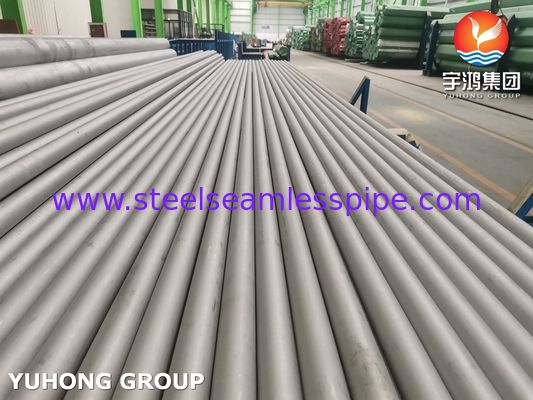

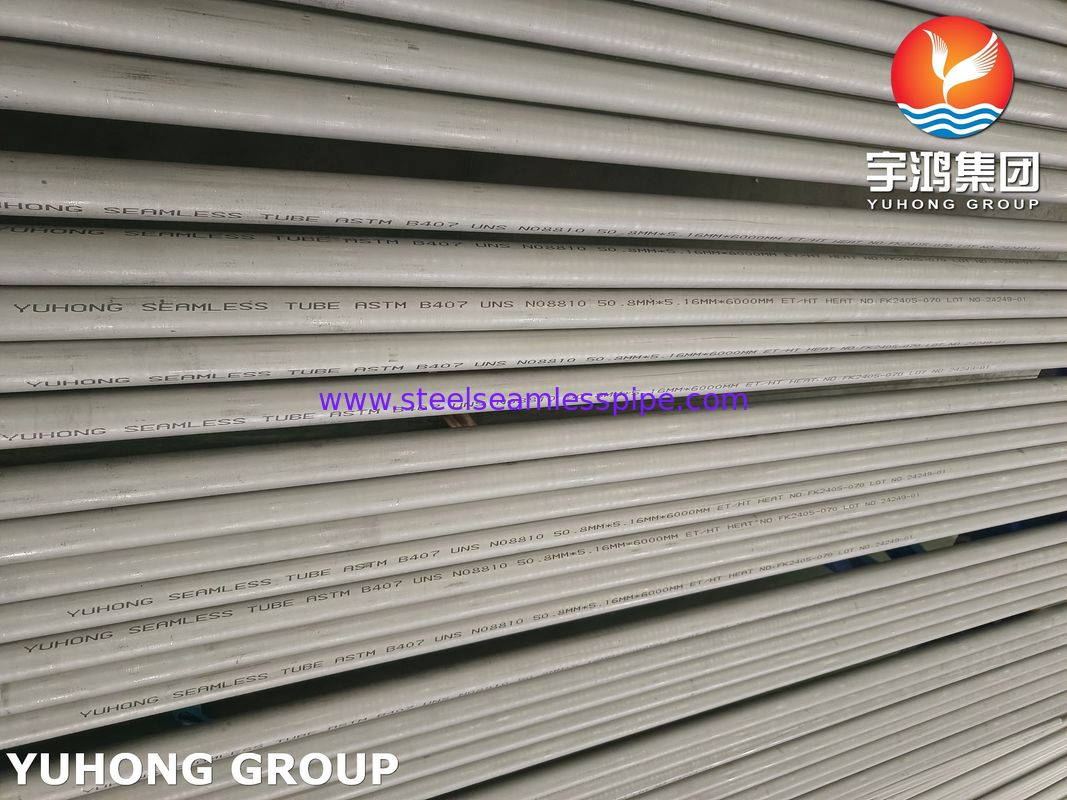

ASTM B407 UNS N08810(800H) Nickel-Iron-Chromium Alloy Seamless Tube

This product is a seamless tube manufactured according to the ASTM B407 standard from a nickel-iron-chromium alloy (UNS N08810, commonly known as 800H). This alloy is engineered to withstand extreme high-temperature and corrosive environments. Its crucial "H" designation indicates it has undergone a specific heat treatment (solution annealing) to achieve a coarse grain structure, which significantly enhances its creep and rupture strength at elevated temperatures. It has the same base composition as Incoloy 800 but exhibits significantly higher creep strength.

The seamless tube is highly valued for its exceptional resistance to oxidation, carburization, and its outstanding stability under high-stress, high-temperature conditions. This higher strength is achieved through careful control of the carbon, aluminum, and titanium contents, combined with heat treatment. It is used in petrochemical processes, power plant heater and reheater piping, industrial furnaces, and heat treatment equipment.

1.Chemical & Mechanical Properties

| ASTM B407 UNS N08810 Chemical Composition (%) |

|

Ni

|

Cr

|

Fe

|

Mn

|

Cu

|

Si

|

S

|

Al |

Ti |

|

30%-35%

|

19%-23% |

≥39.5% |

≤1.5% |

≤0.75% |

≤1.0% |

≤0.015% |

0.15%-0.60% |

0.15%-0.60% |

The chemical composition is the same as N08800(800) and N08811(800HT)

Mechanical Properties

| Property |

Standard Value |

| Tensile Strength |

450 MPa |

| Yield Strength (0.2% offset) |

170 MPa |

| Elongation |

30% |

| Condition(Temper) |

hot-finished annealed or cold-worked annealed |

| Operating temperature |

≥ 593℃

|

2. Key Adventages

- Exceptional High-Temperature Strength and Creep Resistance

The "H" designation signifies solution annealing to achieve a coarse grain structure. This provides unparalleled resistance to slow plastic deformation (creep) and fracture under sustained high-temperature and high-stress conditions (typically above 600°C), ensuring an exceptionally long service life.

- Outstanding Oxidation and Carburization Resistance

The high chromium (Cr) content forms a dense, stable chromia scale that protects against further oxidation. The high nickel (Ni) content effectively resists the inward diffusion of carbon (carburization), preventing embrittlement, dusting, and premature degradation of properties.

- Excellent Resistance to a Variety of Corrosive Environments

It demonstrates good resistance to both reducing and oxidizing atmospheres, as well as organic acids and many alkaline solutions. This allows it to handle complex process streams, giving it a very broad application range.

- Reliability and Integrity of Seamless Construction

Being manufactured by extrusion or piercing, seamless tubes have no weld seam, which is a potential weak point. This ensures superior mechanical strength and reliability under high pressure, high temperature, and thermal cycling conditions, eliminating the risk of weld corrosion and failure.

3. Key Applications

- Petrochemical Industry: Cracking Furnace Tubes

- Chemical Processing: Heat Exchangers, Reactor Piping, Catalyst Support Tubes

- Heat Treatment & Industrial Furnacing: Radiant Tubes, Furnace Rolls

- Power & Energy Generation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!